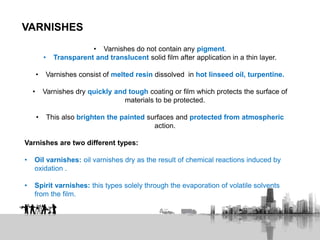

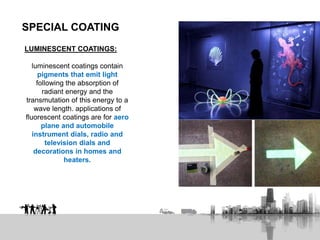

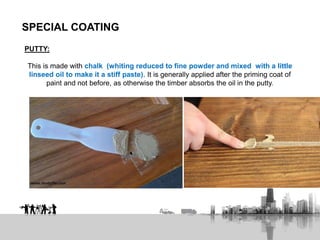

This document discusses different types of paints used in construction, including their composition and uses. It covers oil paints, water paints, aluminum paints, cellulose paints, water-repellent paints, distempers paints, varnishes, and special coatings. Oil paints are not ready-mixed and require grinding in oil. Water paints contain both oil and water in an emulsion. Aluminum paints protect surfaces from corrosion. Cellulose paints are commonly used as spray paints. Distempers are a form of water paint used for interior decoration. Varnishes form a transparent protective film and are divided into oil and spirit types. Special coatings include fire retardants