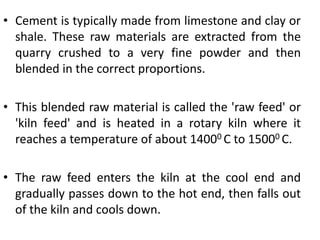

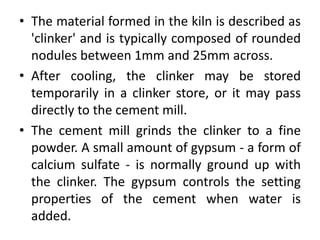

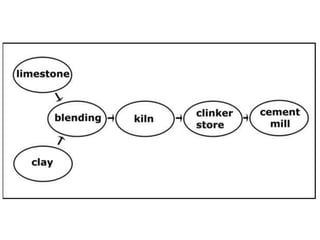

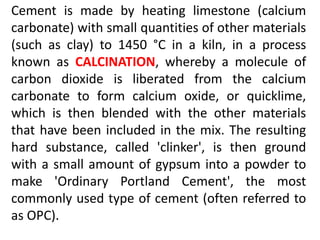

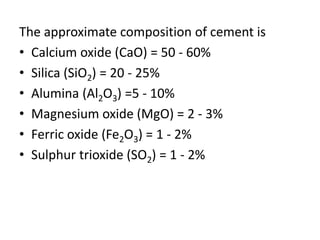

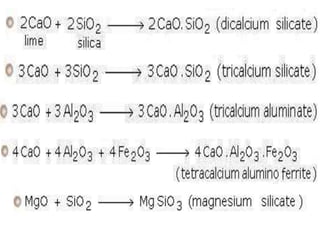

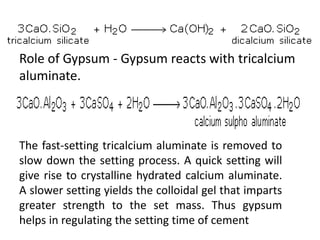

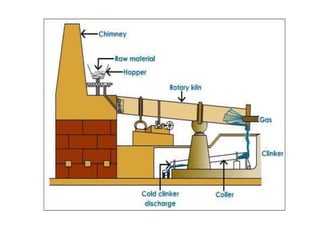

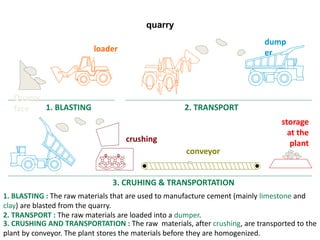

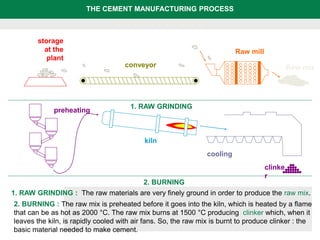

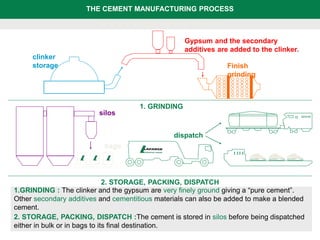

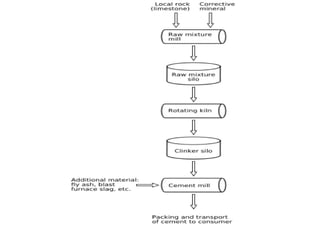

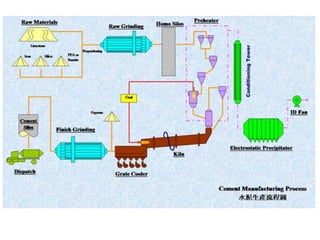

Cement is a finely ground mineral powder, primarily made from limestone and clay, that acts as a binding agent when mixed with water, sand, and gravel to create concrete. The manufacturing process involves heating raw materials in a kiln to produce clinker, which is then ground with gypsum to form ordinary Portland cement. Various types of blended cements incorporate supplementary materials like fly ash or slag to enhance properties such as strength, setting time, and heat resistance.