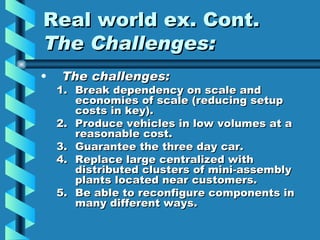

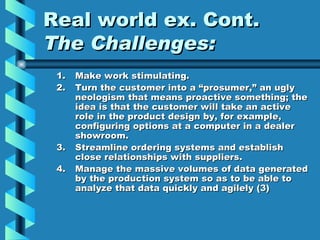

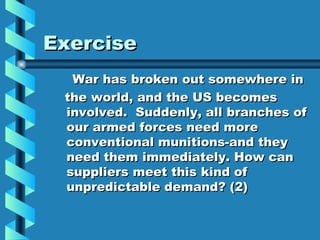

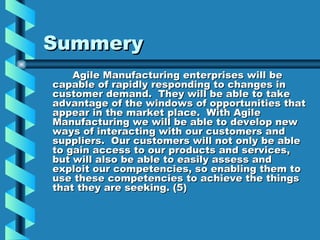

The document discusses the concept of agile manufacturing, which integrates organization, people, and technology to respond rapidly to customer demands in a competitive landscape. It emphasizes the need for flexibility, quick design and production processes, and collaboration between companies, as well as outlining key strategies and principles for transitioning to agile manufacturing. The real-world example of Japanese car makers illustrates the challenges and benefits of adopting this manufacturing approach.