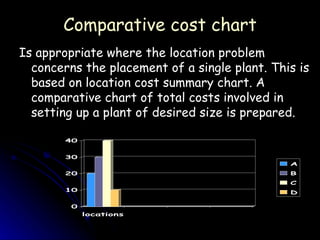

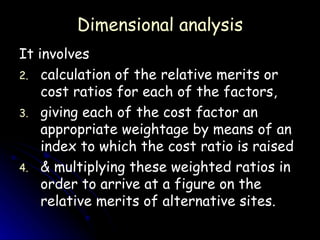

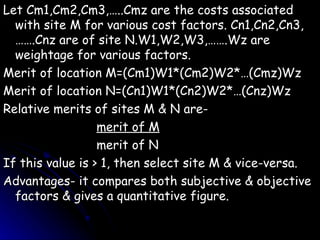

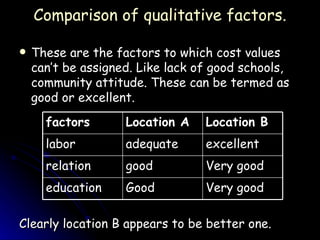

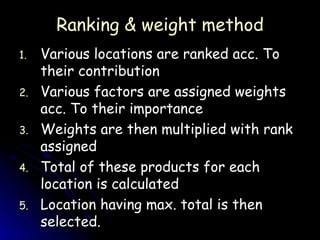

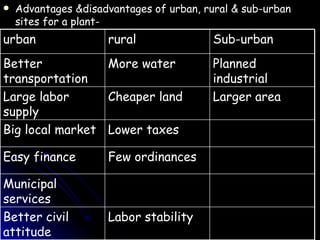

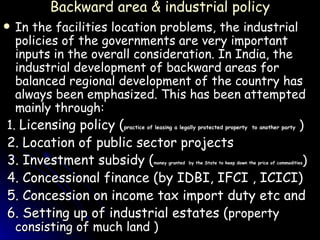

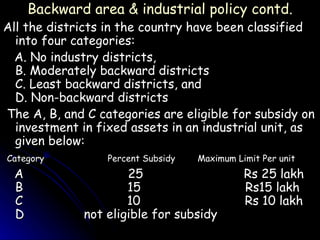

Plant location refers to establishing an industry at a particular place. There are two types: localization/centralization concentrates similar industries in one area, while delocalization/decentralization spreads them out. Key factors in choosing a location include availability of resources like materials, labor, transportation; market access; and operating costs. Methods for evaluating potential sites include comparative cost charts, which assess total costs, and dimensional analysis, which assigns weights to qualitative factors.