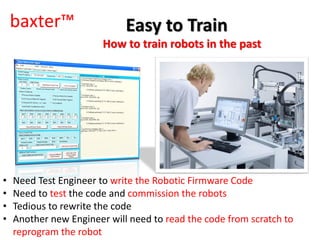

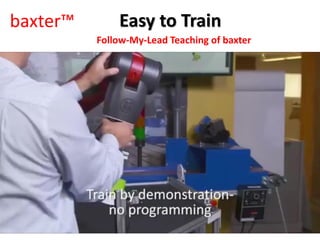

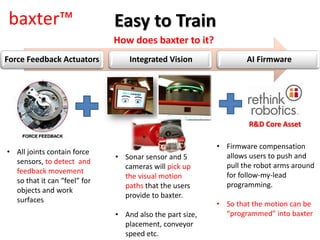

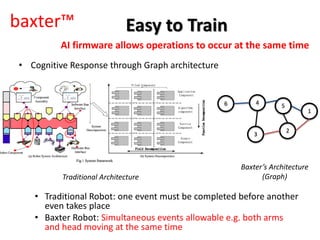

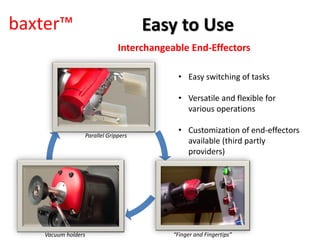

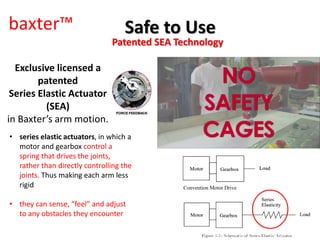

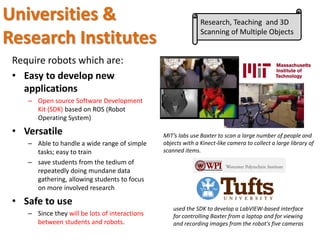

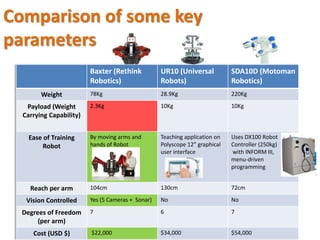

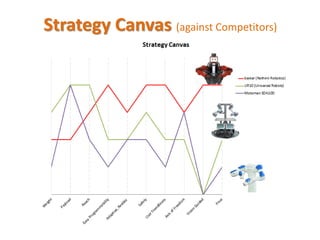

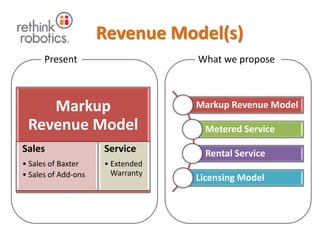

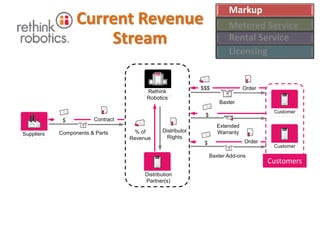

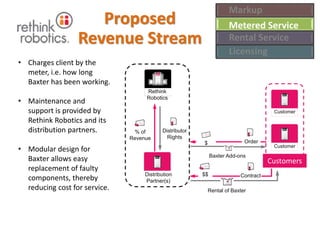

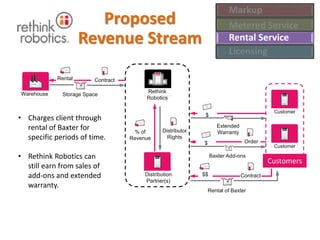

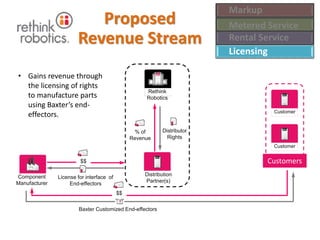

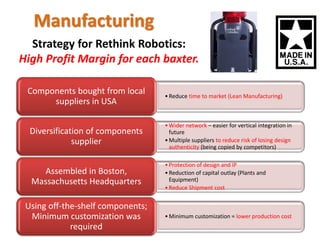

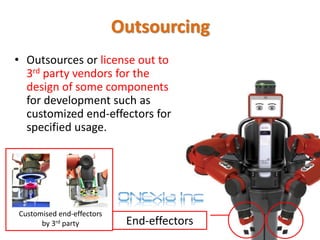

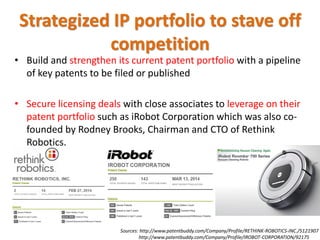

The document outlines the business model and features of Baxter, a collaborative robot (cobot) designed for simple tasks in various industries. It emphasizes Baxter's user-friendly interface, ease of training, and safety, making it suitable for small and medium-sized enterprises. The document also discusses the competitive landscape, potential revenue streams, and the company's strategic approach to research and development.