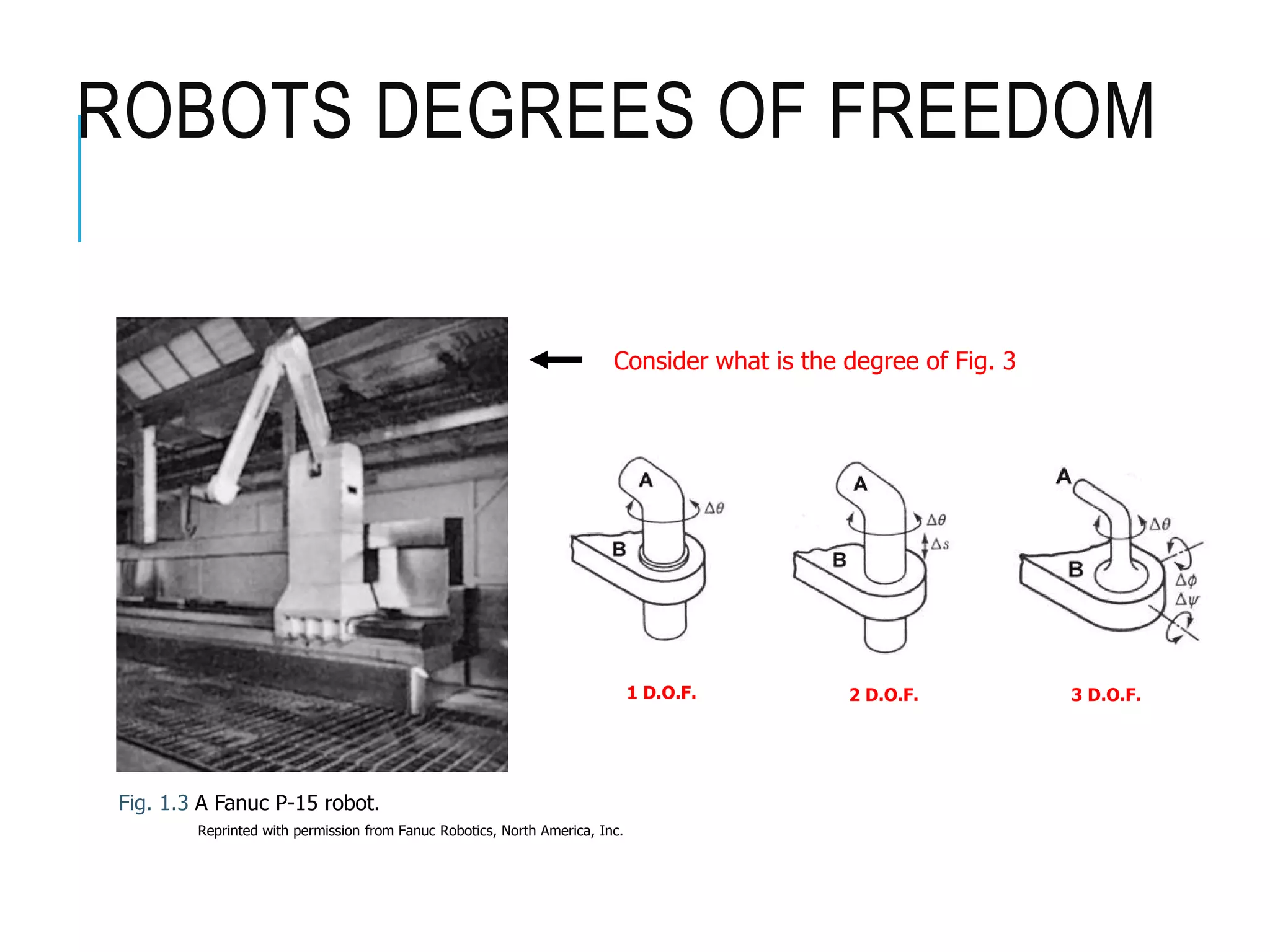

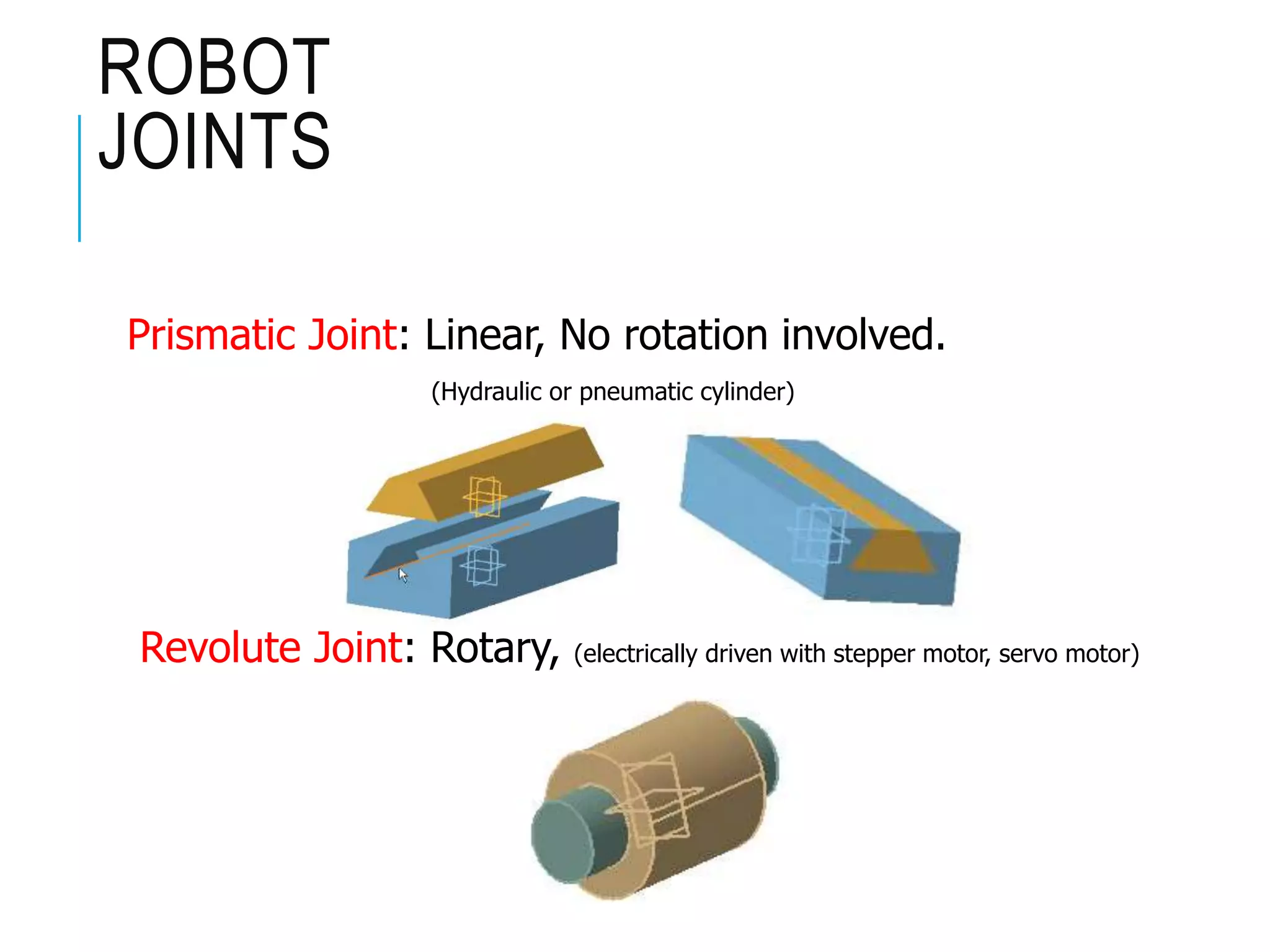

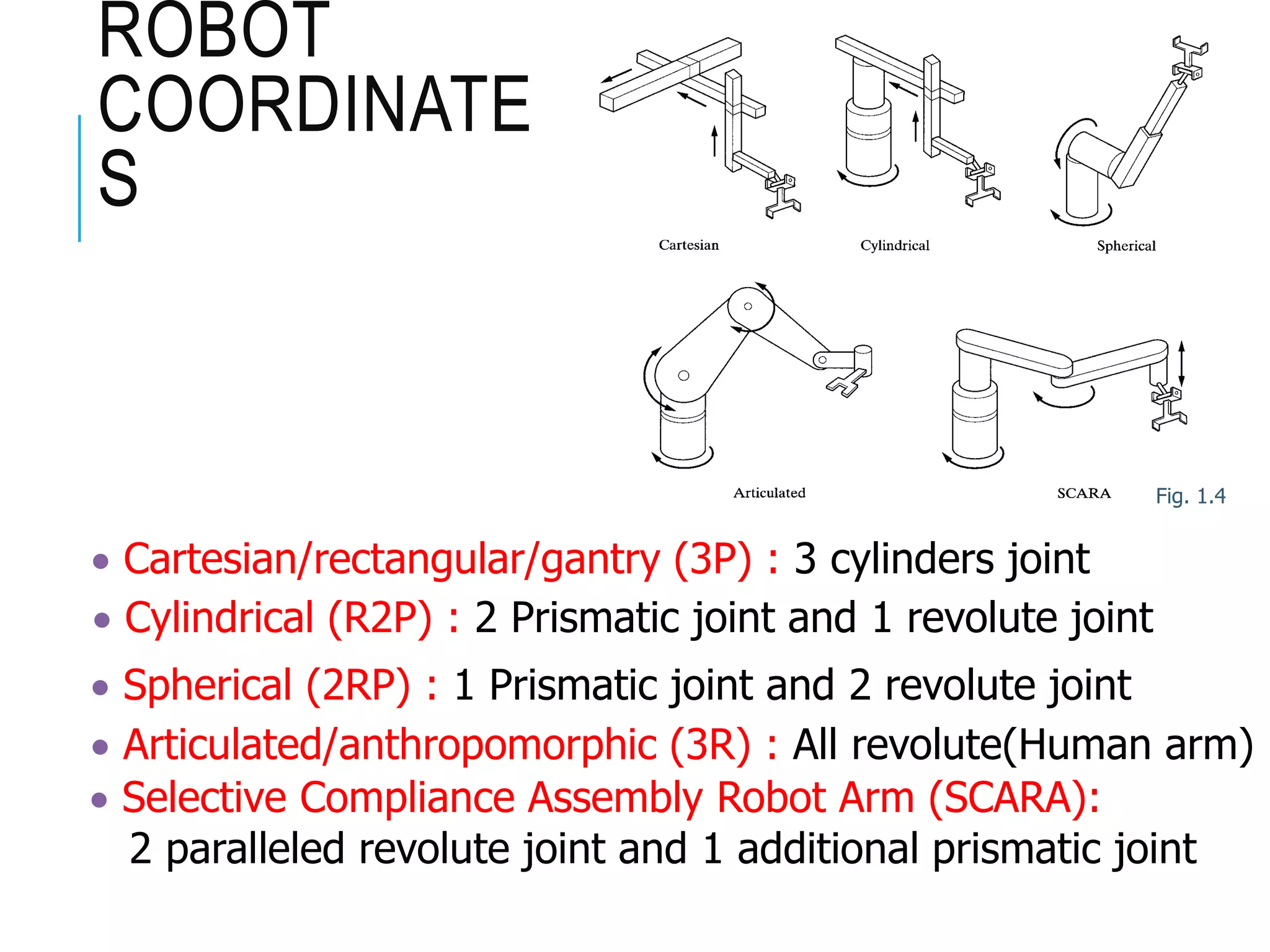

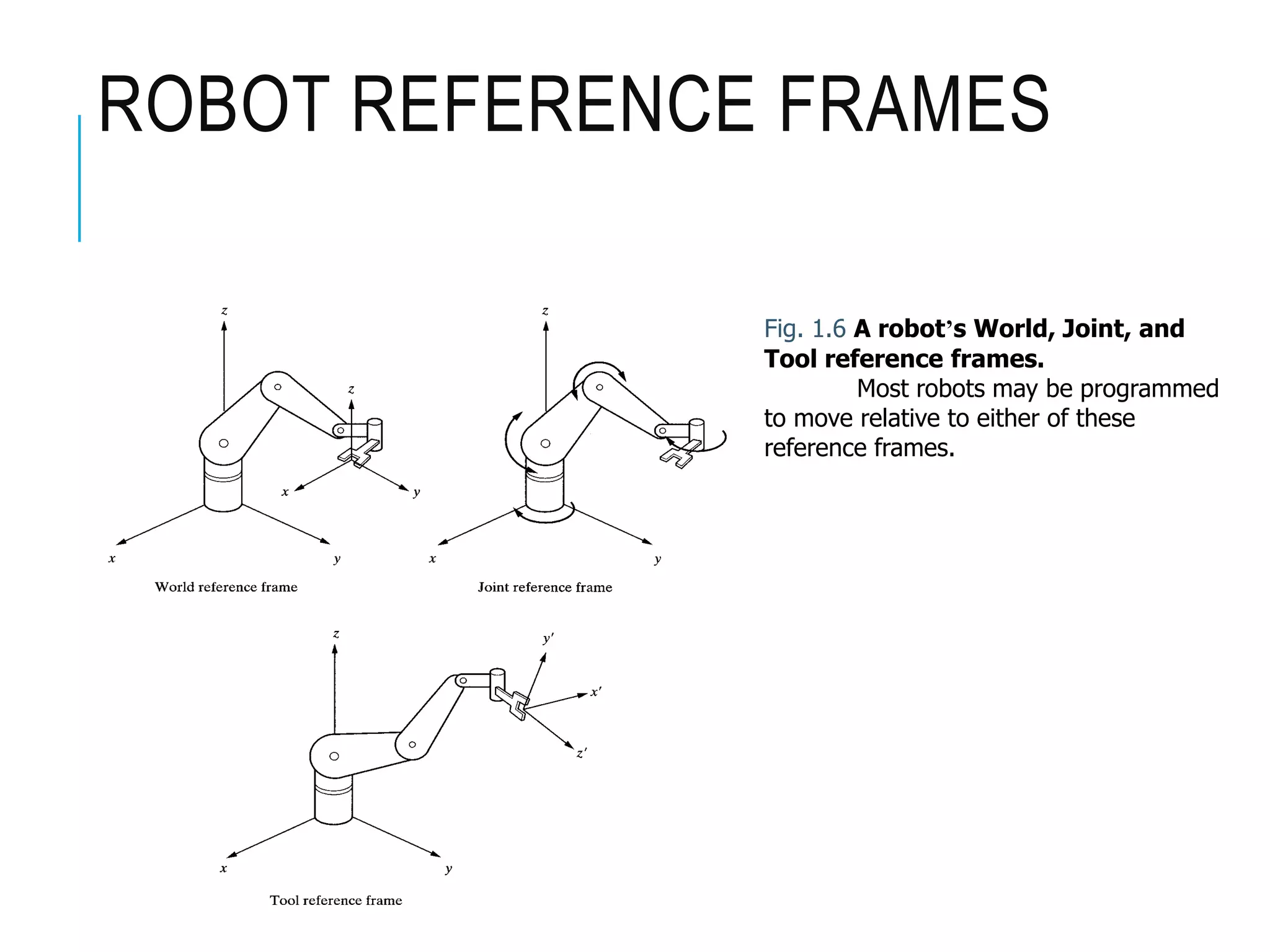

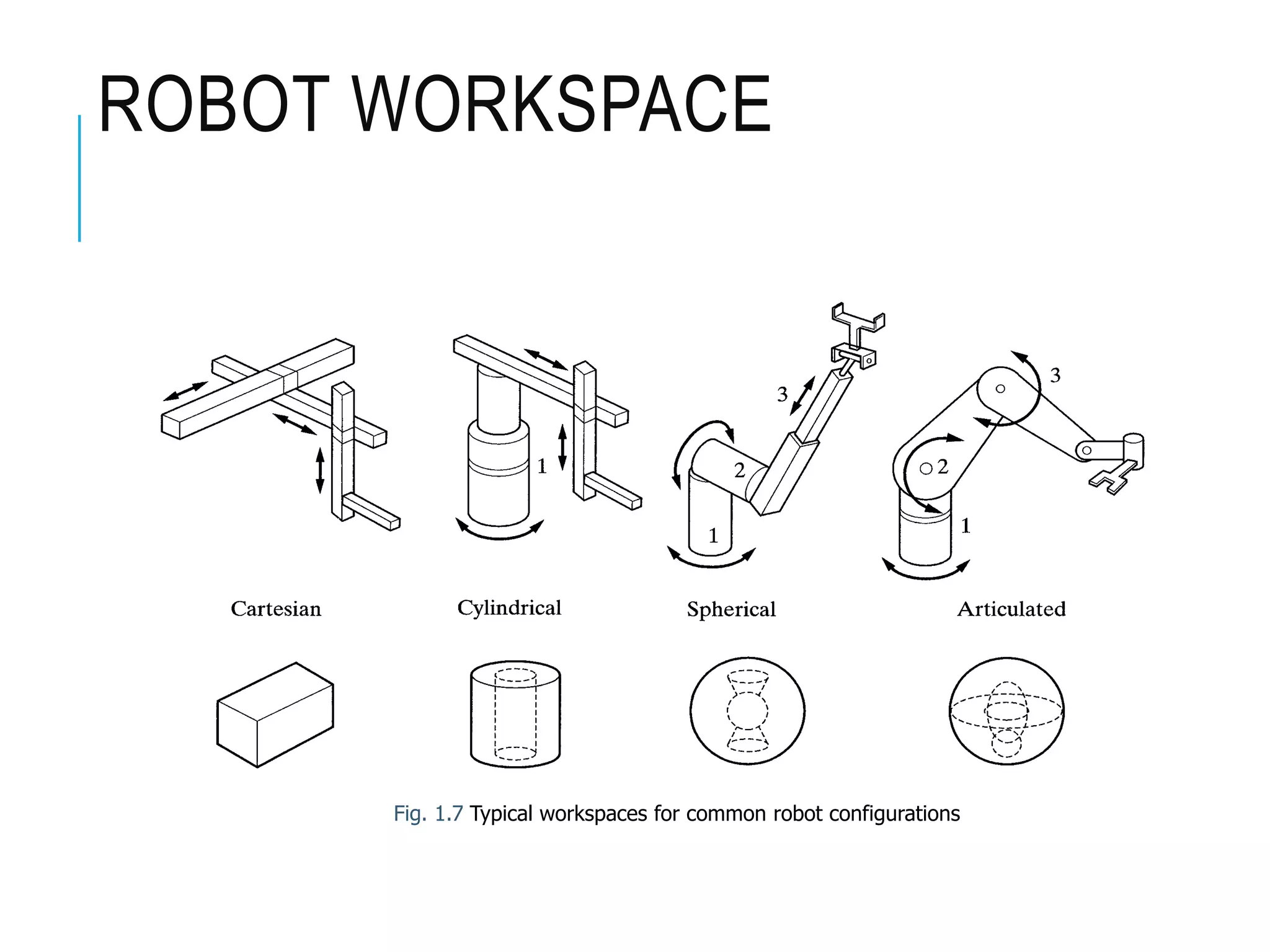

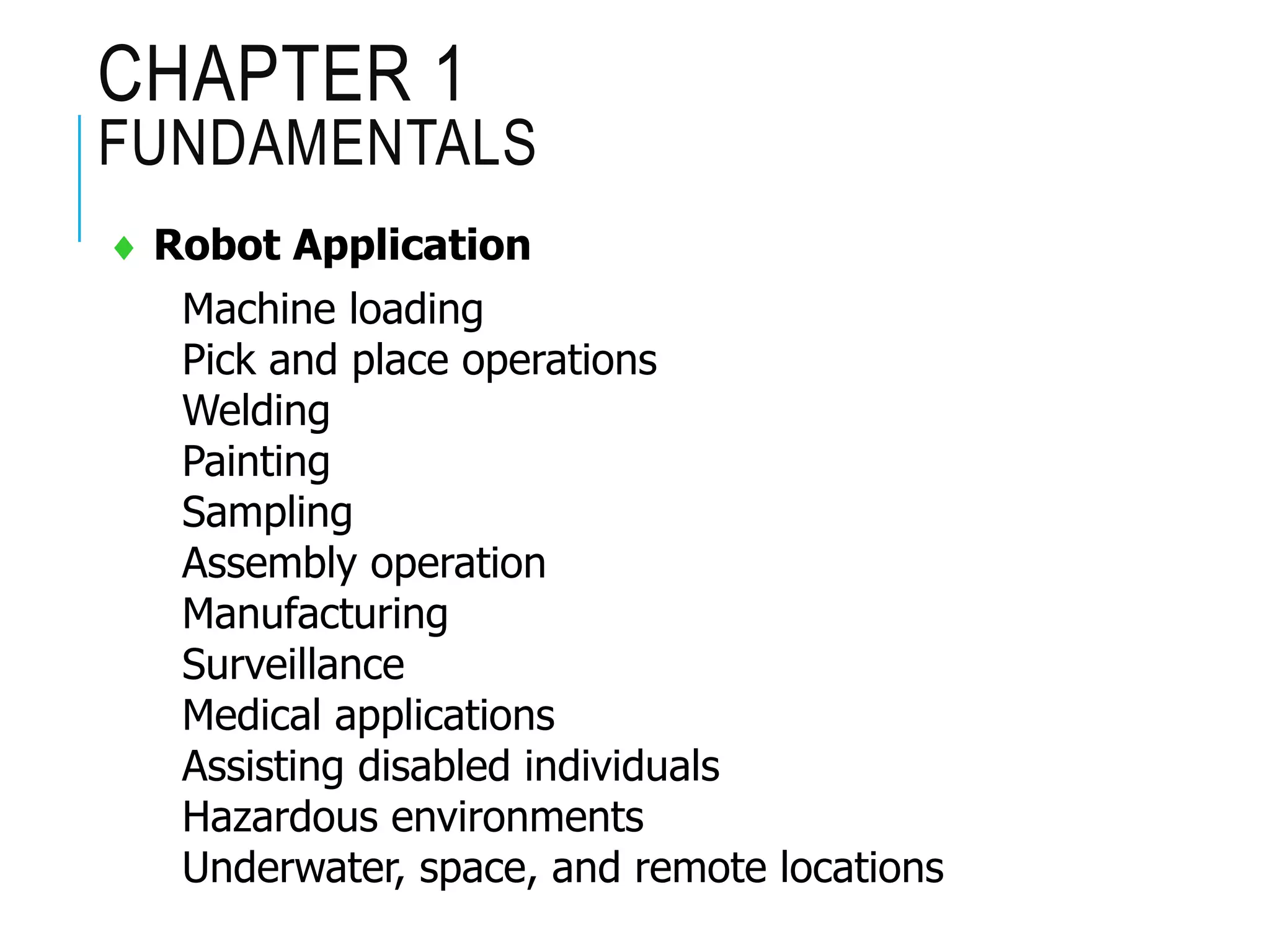

This document provides an introduction to robotics, including definitions of robots, classifications of robots, the parts of a robot, robot joints and coordinate systems, robot workspaces, robot characteristics, robot languages, applications of robots, and the advantages and disadvantages of robots. It defines a robot as a reprogrammable manipulator designed to perform tasks through variable programmed motions. Robots are classified based on their level of autonomy and programming. The key parts of a robot are its manipulator, pedestal, controller, end effectors, and power source.