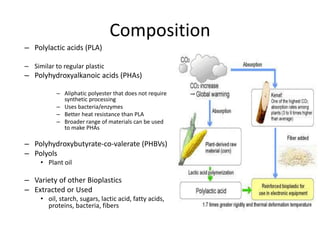

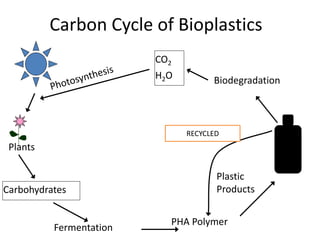

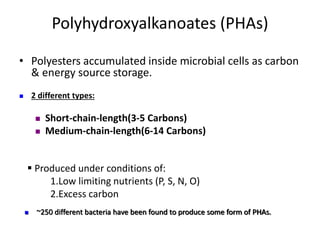

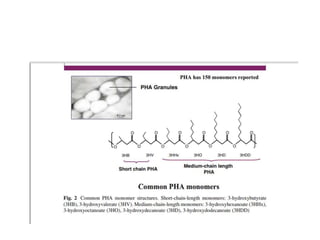

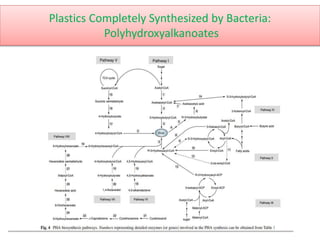

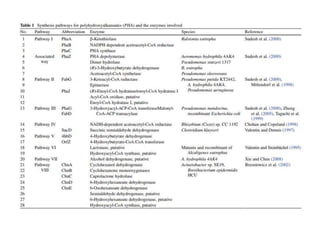

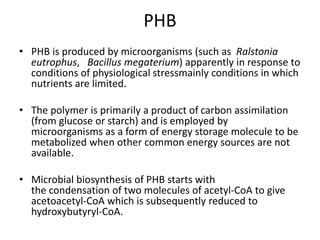

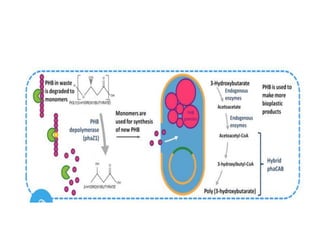

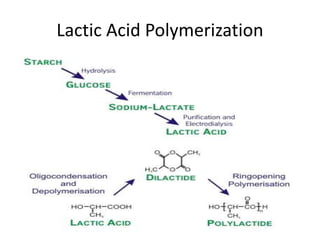

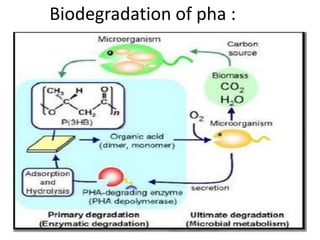

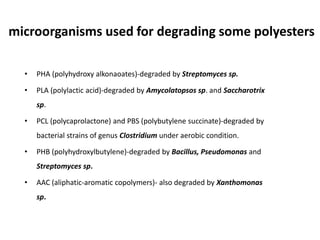

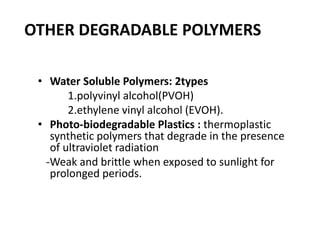

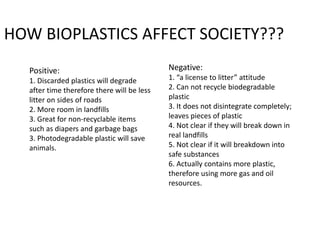

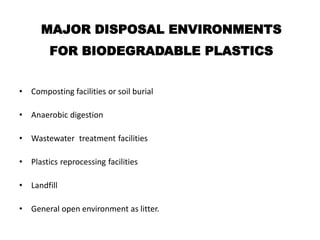

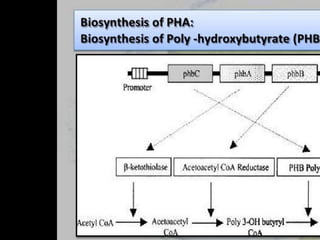

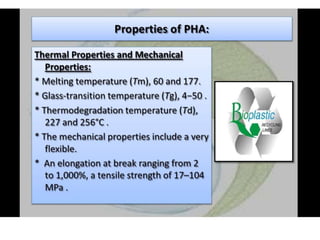

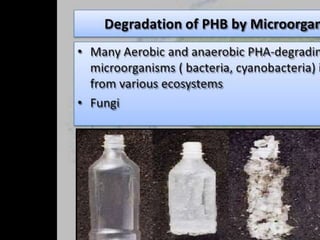

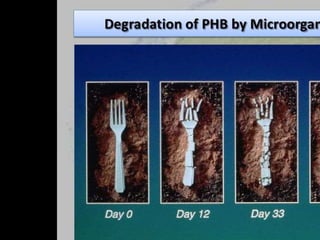

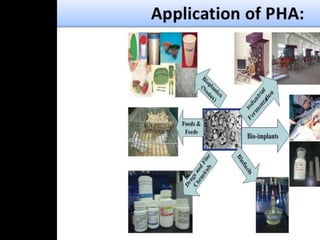

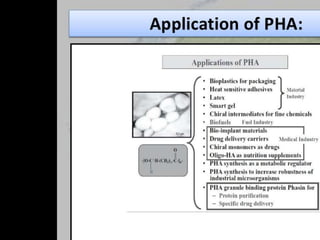

This document discusses bioplastics, which are plastics derived from renewable biomass sources such as vegetable oils, cornstarch, and pea starch. It notes that bioplastics are designed to biodegrade and can break down in either aerobic or anaerobic environments depending on how they are manufactured. Common types of bioplastics include polylactic acid (PLA), polyhydroxyalkanoic acids (PHAs), and polyhydroxybutyrate-co-valerate (PHBVs). The document also discusses the synthesis and production of bioplastics like PHAs and PHB by microorganisms, as well as their applications in packaging, catering, gardening, medical products, and sanitary products