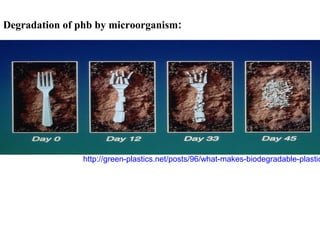

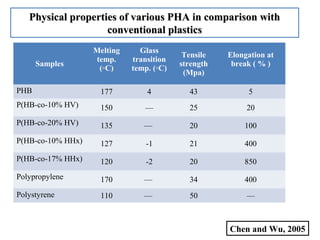

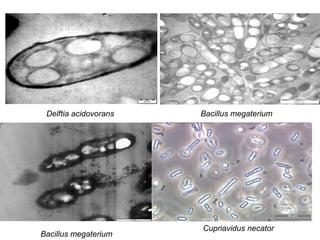

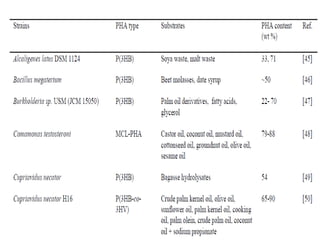

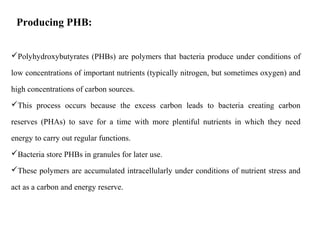

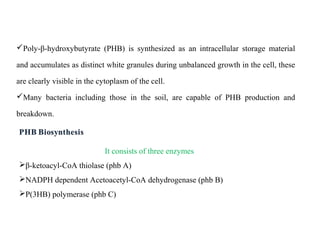

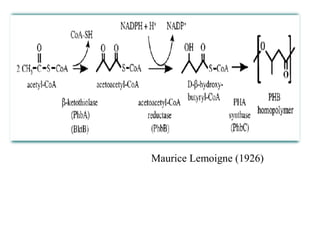

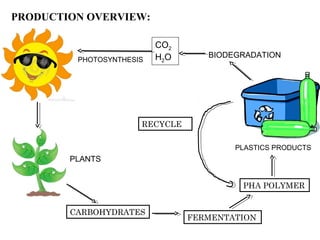

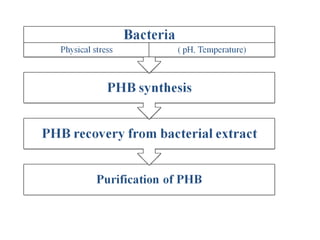

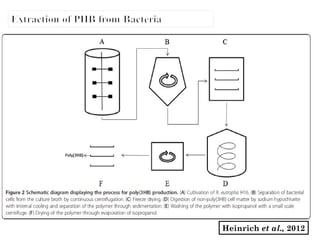

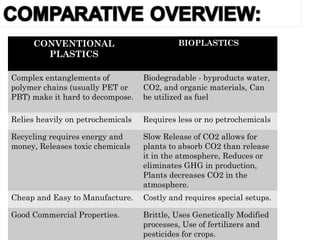

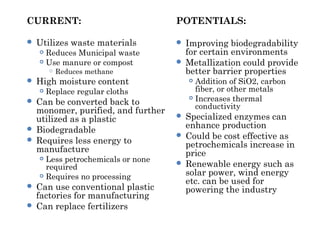

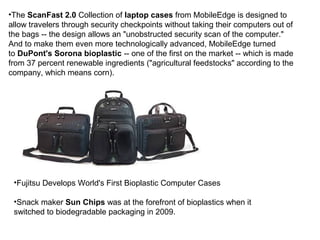

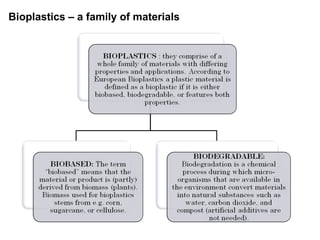

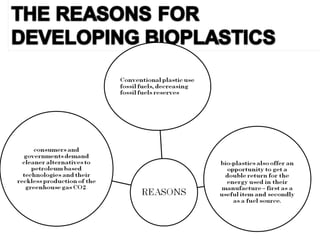

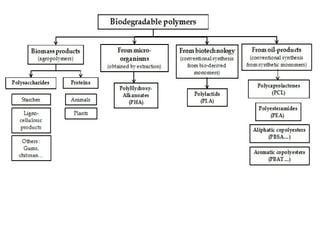

The document discusses bioplastics, particularly polyhydroxybutyrates (PHB), their production from renewable biomass, and their biodegradable properties compared to conventional plastics. It outlines the advantages of bioplastics, such as reduced greenhouse gas emissions and potential applications in various industries. The text emphasizes the evolving technology that may further enhance the benefits and cost-effectiveness of bioplastics in the future.

![Introduction:

Polyhydroxybutyrates (PHBs) are members from family of polyesters known as

Polyhydroxyalkanoates (PHAs).

Accumulated in intracellular granules by Gram-positive and Gram-negative

microorganisms.

PHB are produced when there is excess carbon source with the limitation of one of

the essential nutrients.

Also known as Biopolymers as they are produced from microorganisms.

They are thermoplastic polymers and are totally biodegradable

Many different types of PHAs are available and PHB is the most common one

Empirical formula - [C4H6O2]n

Structural formula for the linear chain of PHB](https://image.slidesharecdn.com/bioplastics-160227035407/85/Bioplastics-13-320.jpg)