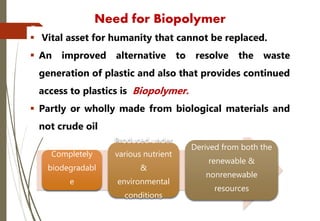

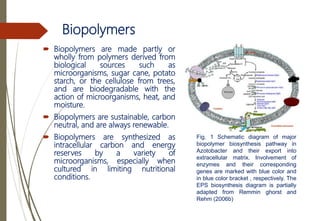

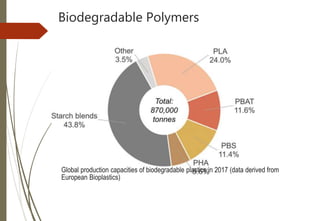

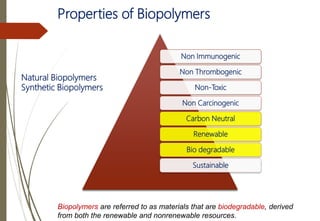

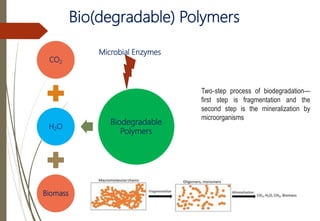

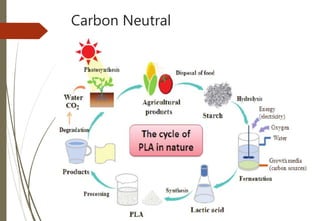

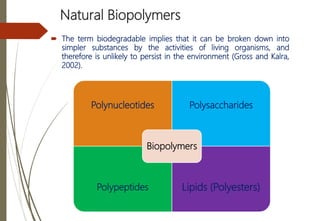

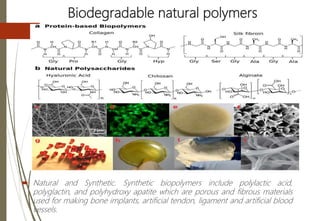

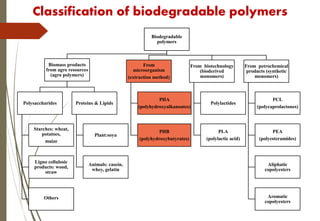

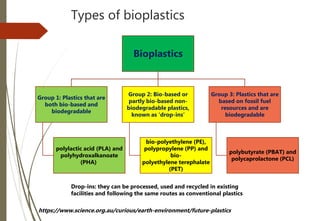

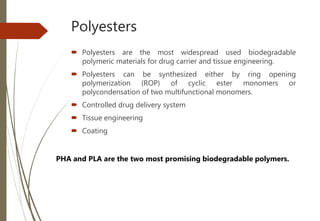

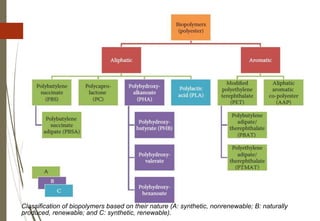

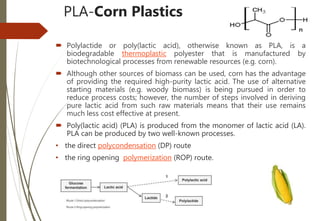

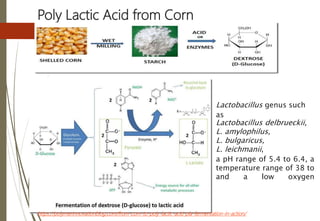

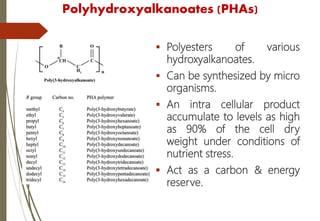

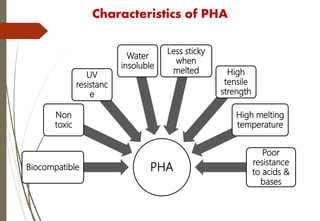

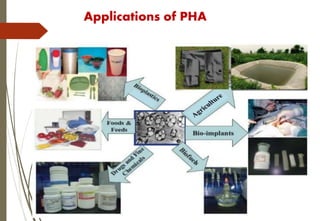

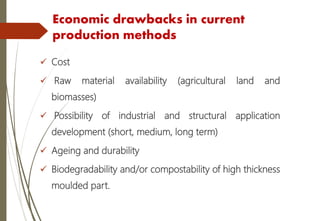

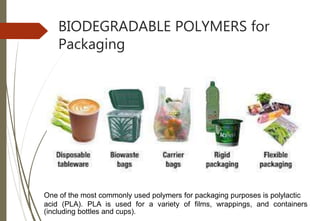

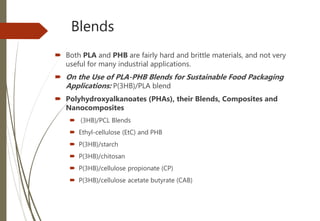

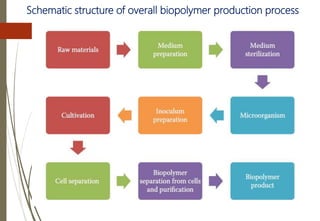

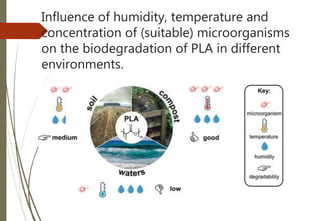

Biodegradable polymers are derived from biological sources such as plants and microorganisms. They include natural polymers like starch, cellulose, and proteins as well as synthetic polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) that are biodegradable. PLA is commonly used for packaging and is produced from corn via fermentation. PHAs can be produced by microorganisms and have applications in drug delivery and tissue engineering. While biodegradable polymers address issues with conventional plastics, their production and properties need further improvement for widespread adoption. Continued research aims to enhance production efficiency and material properties.