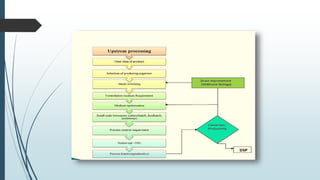

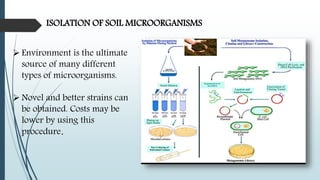

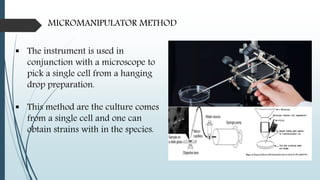

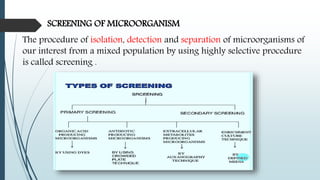

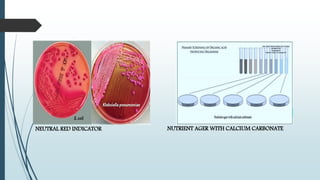

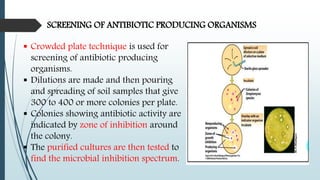

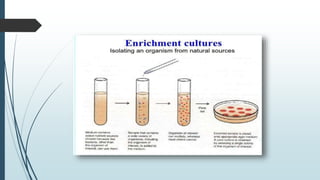

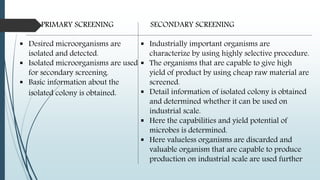

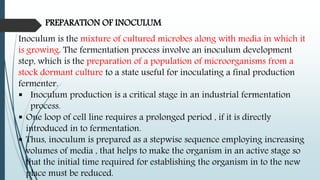

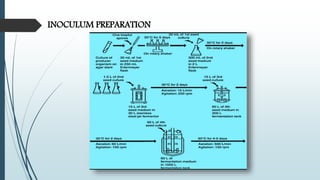

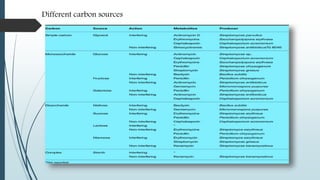

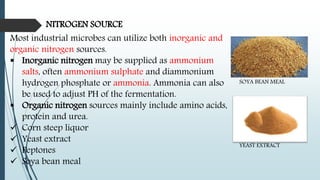

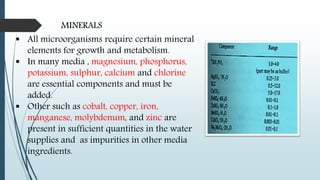

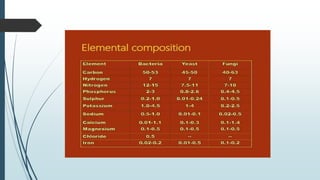

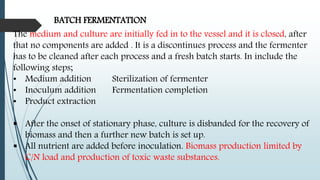

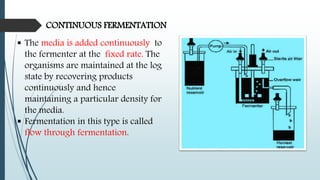

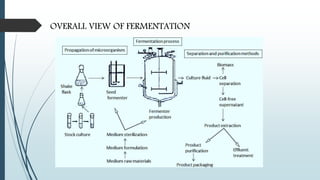

The document summarizes key aspects of upstream processing in fermentation. The upstream process includes culture isolation and screening to obtain desired microorganisms, inoculum preparation using increasing media volumes to actively grow cultures, and media formulation and sterilization. Primary screening qualitatively determines which microorganisms can produce compounds of interest, while secondary screening characterizes industrially important organisms and determines yield potentials under different conditions to select microbes suitable for industrial use. Important steps in inoculum preparation and considerations for media composition like carbon, nitrogen, minerals and growth factors are also outlined.