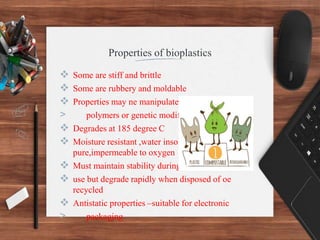

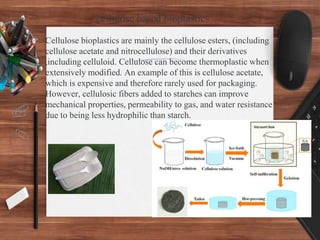

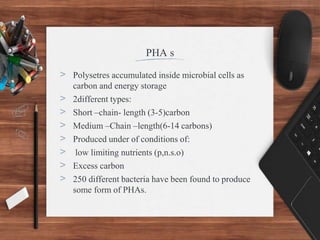

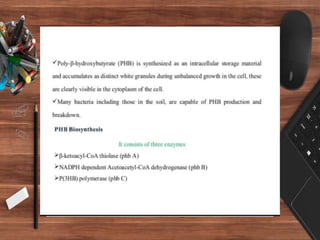

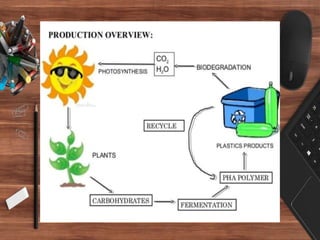

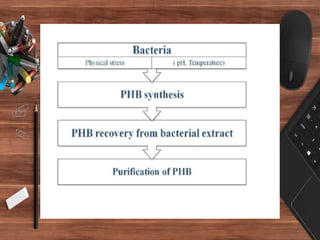

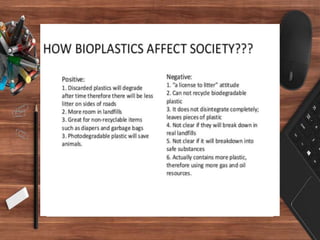

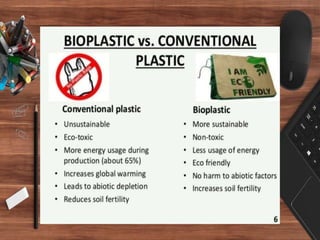

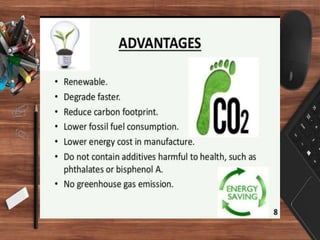

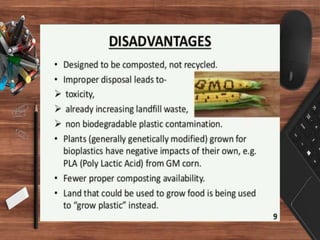

The document discusses bioplastics, which are moldable plastics derived from renewable resources and often biodegradable, contrasting them with traditional petroleum-based plastics. It covers the types of bioplastics, their properties, production methods, and environmental benefits, particularly focusing on starch-based and cellulose-based bioplastics. Additionally, it highlights the production process of polylactic acid (PLA) and polyhydroxyalkanoate (PHA), their applications, and environmental impacts.