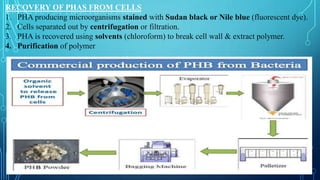

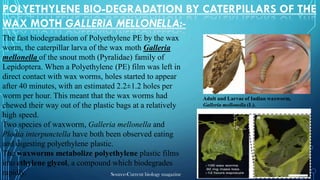

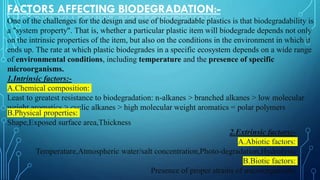

This document discusses biodegradable plastics and polyhydroxybutyrate (PHB). It provides background on biodegradable plastics, including their production from renewable biomass sources and ability to break down naturally. It then focuses on PHB, describing its discovery in bacteria in the 1920s, how it is synthesized intracellularly through three enzymatic reactions, and its properties. Factors that influence biodegradation rates and some commercial producers of PHB are also mentioned.

![TOPIC:-BIO-DEGRADABLE

PLASTICS

Presentation By-

GAGAN KUMAR JANGHEL [M.Sc.III-Sem.]](https://image.slidesharecdn.com/bioplasticppt-230506203913-c1af6199/85/bioplastic-bioplastic-1-320.jpg)

![• In 1862 -The first ever man made plastic was a bio-plastic. It was made from

cellulose nitrate By Wascalles Parkesine.

• In 1888-Polyhydroxyalkanoate (PHA) was first observed in bacteria by

Martinus Beijerinck.

• In 1926-French microbiologist Maurice Lemoigne chemically identified the

polymer after extracting it from Bacillus megaterium.

• In 1983-Imperial Chemical Industries [ICI] manufacture the first broad-

application biodegradable plastic,PHBV, named -Biopol. that was biodegradable

• In 1996, Monsanto discovered a method of producing one of the two polymers in

plants and acquired Biopol with Zeneca, a spinout of ICI, as a result of the

potential for cheaper production.](https://image.slidesharecdn.com/bioplasticppt-230506203913-c1af6199/85/bioplastic-bioplastic-3-320.jpg)

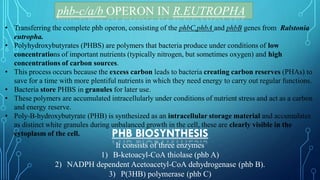

![• The polyester PHB is derived from acetyl-CoA by a sequence of three enzymatic

reactions-

1) [Condensation Step]-First condensation of two molecules of acetyl-CoA is catalyzed

by ẞ-ketothiolase(phbA) to form acetoacetyl-CoA.

2) [Reduction Step]-Acetyl-CoA(phbB) reductase reduces acetoacetyl-CoA to D-ẞ-

hydroxybutyryl-CoA.

3) [Polymerization Step]-It is polymerized by PHA(phbC) synthase to PHB.

Glucose](https://image.slidesharecdn.com/bioplasticppt-230506203913-c1af6199/85/bioplastic-bioplastic-17-320.jpg)