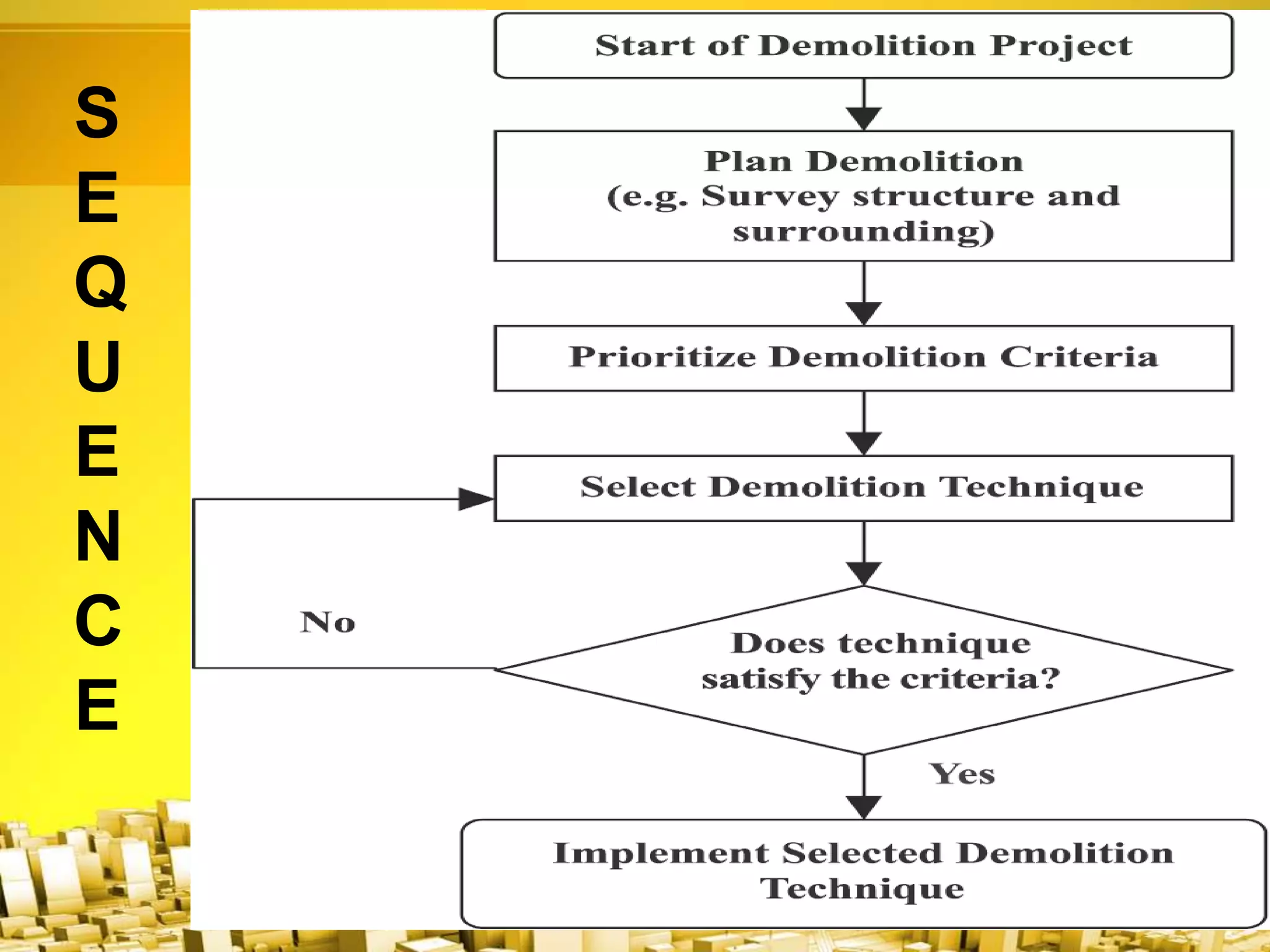

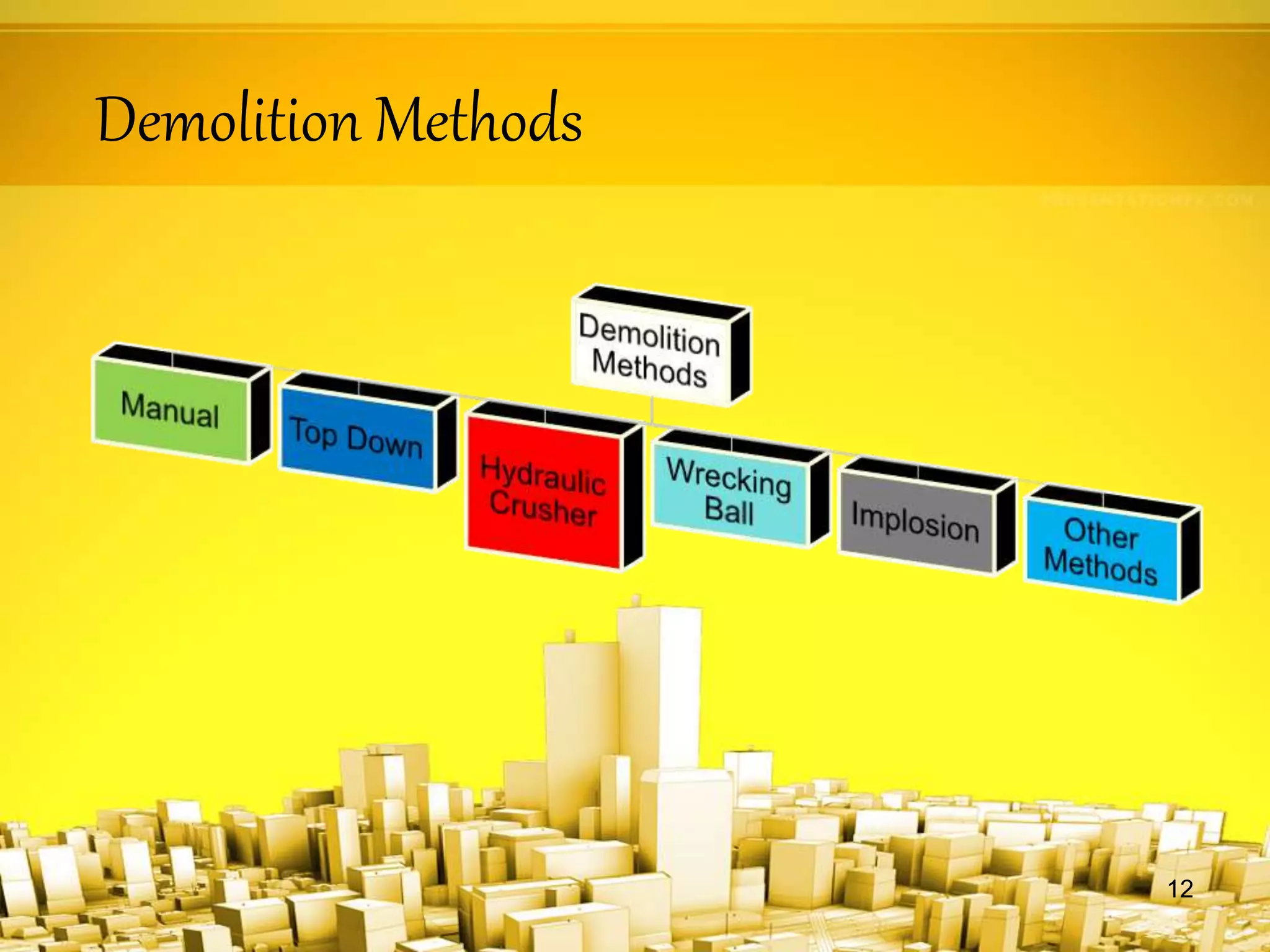

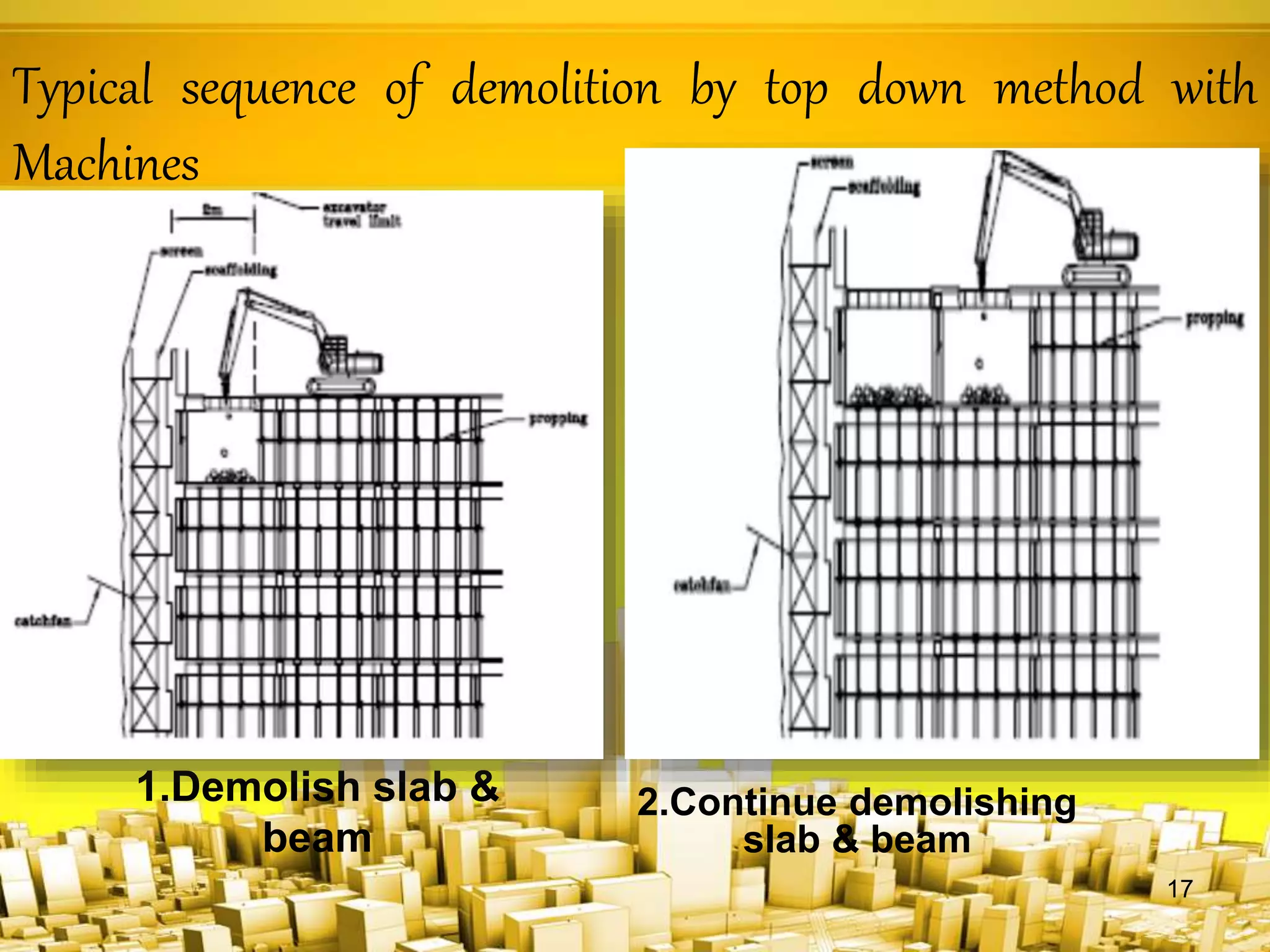

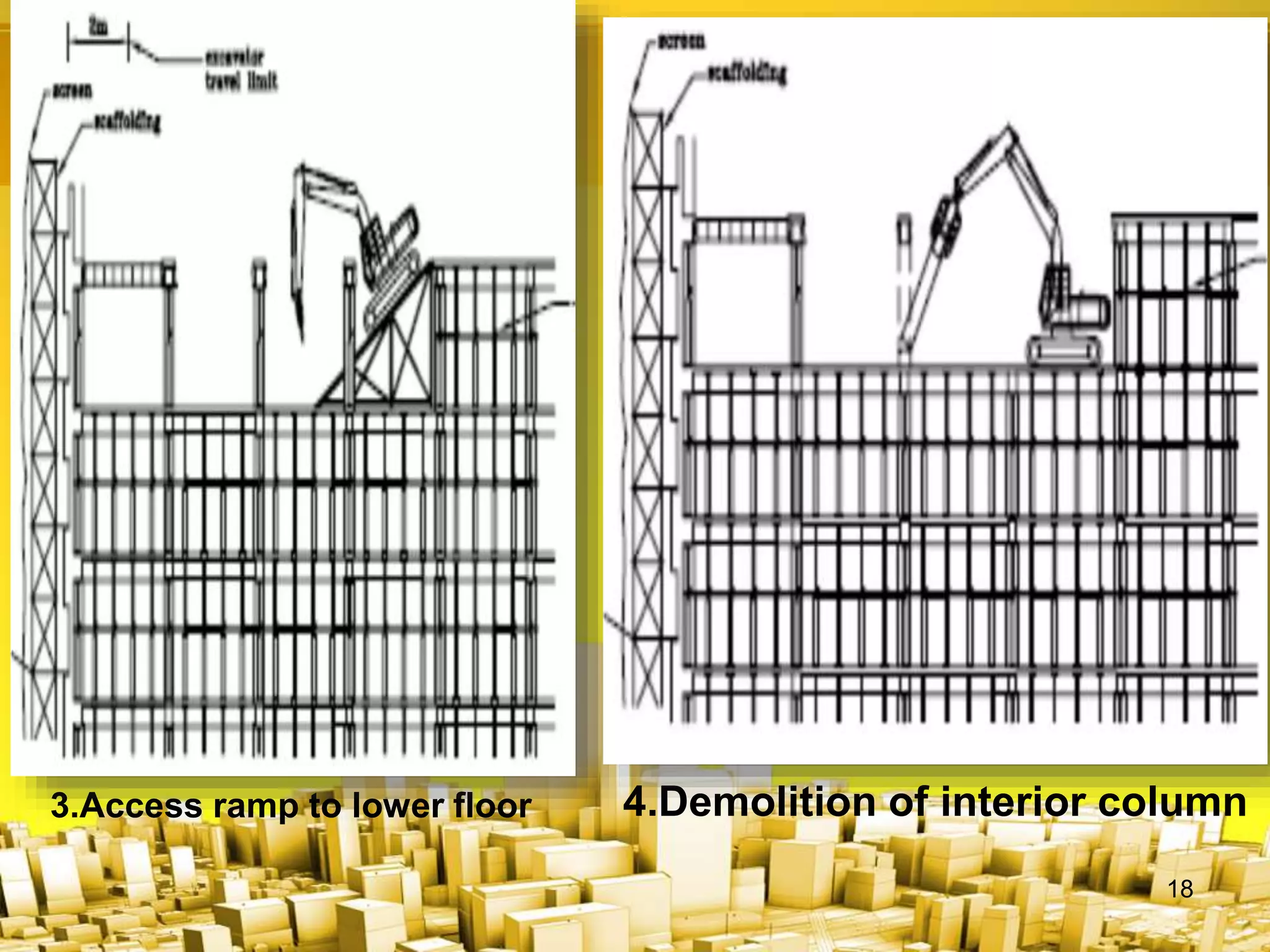

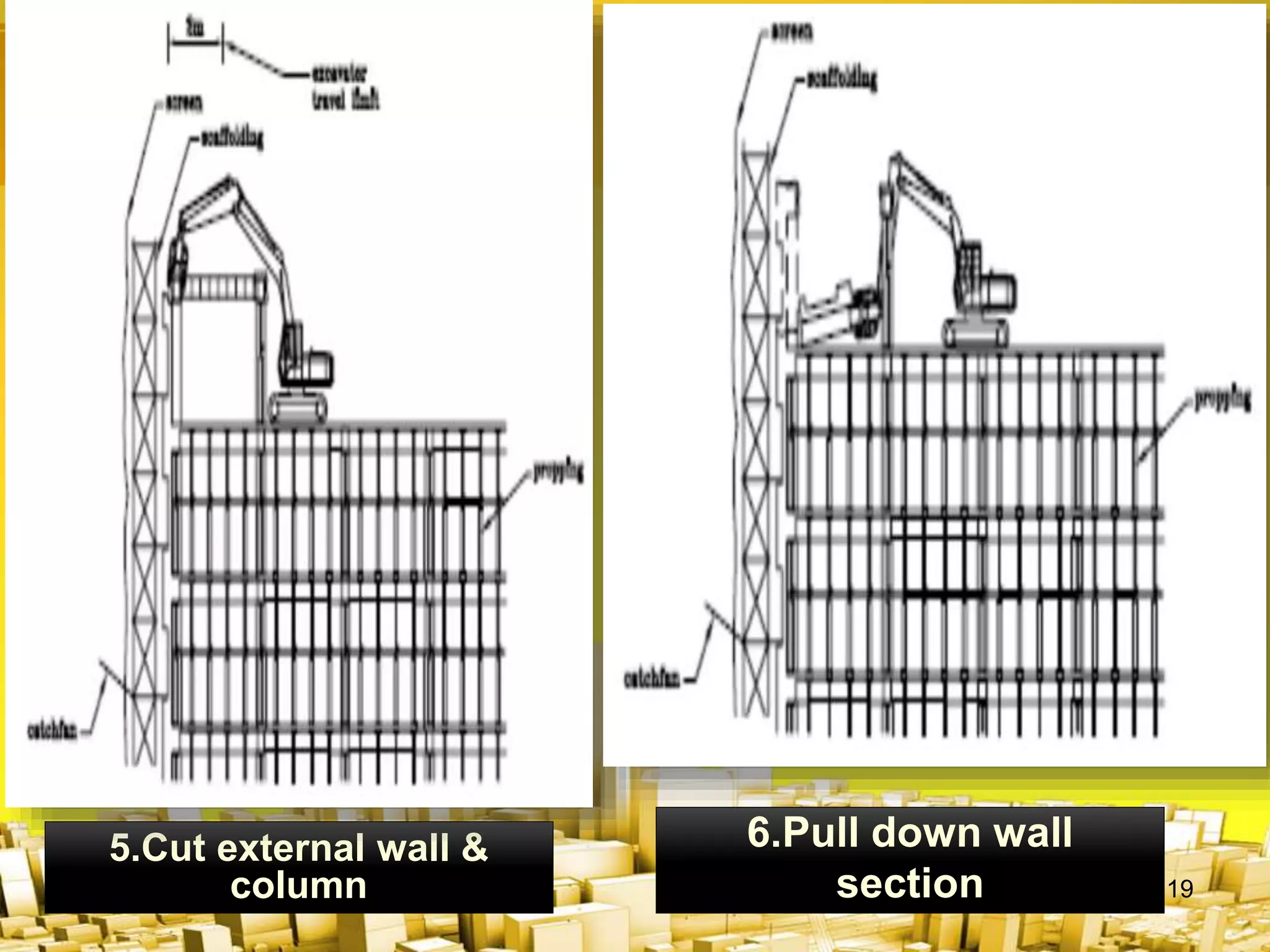

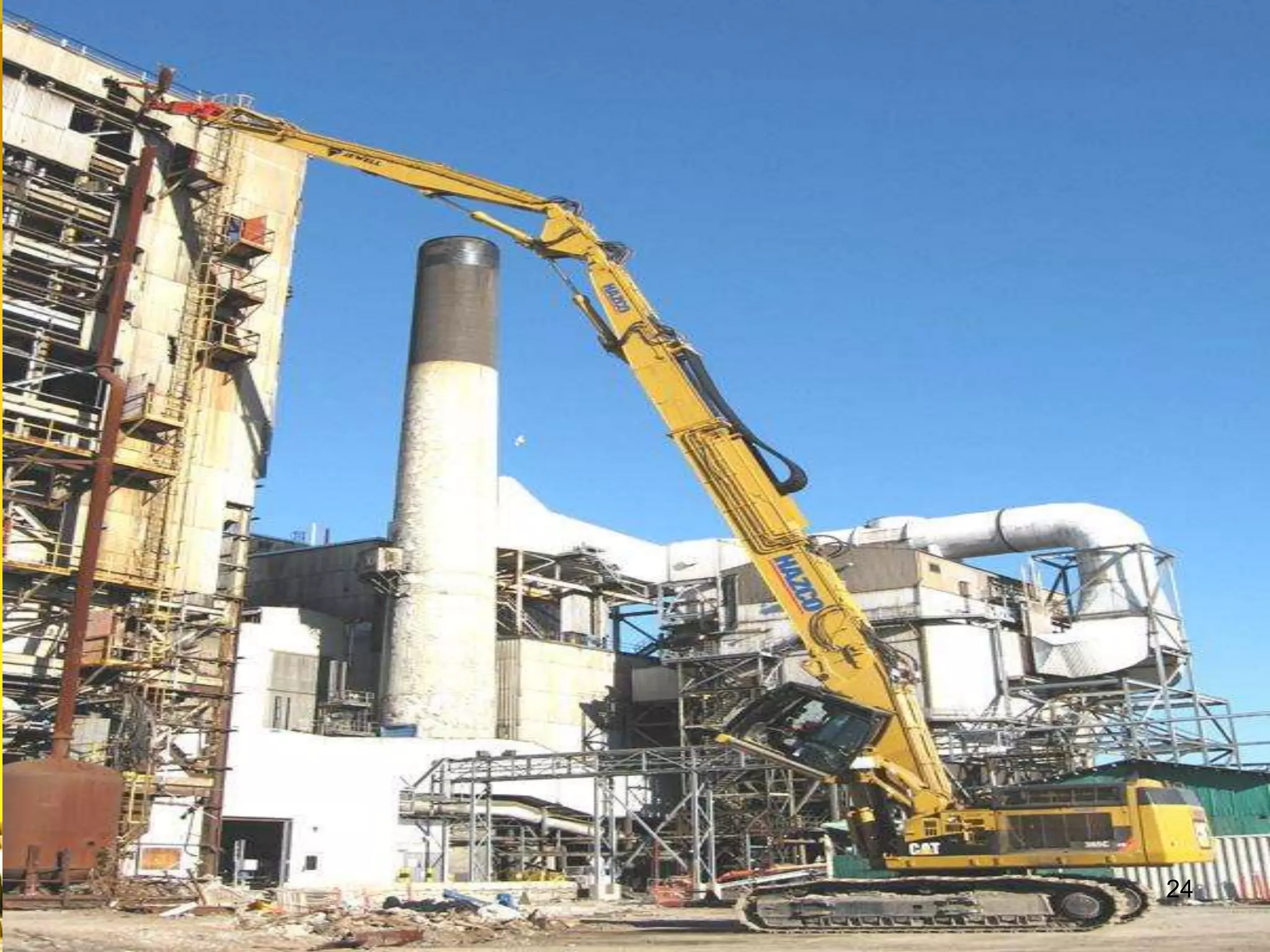

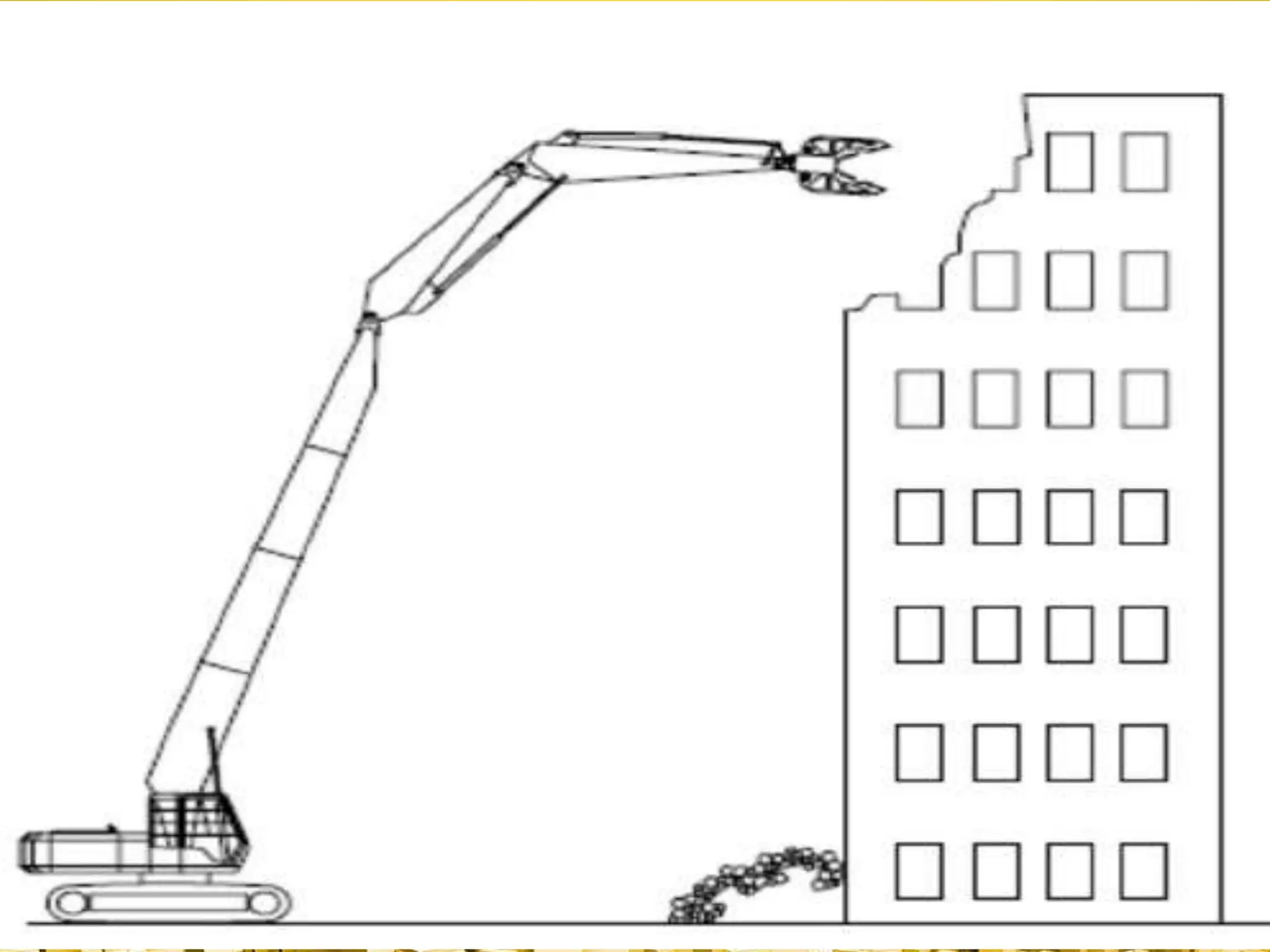

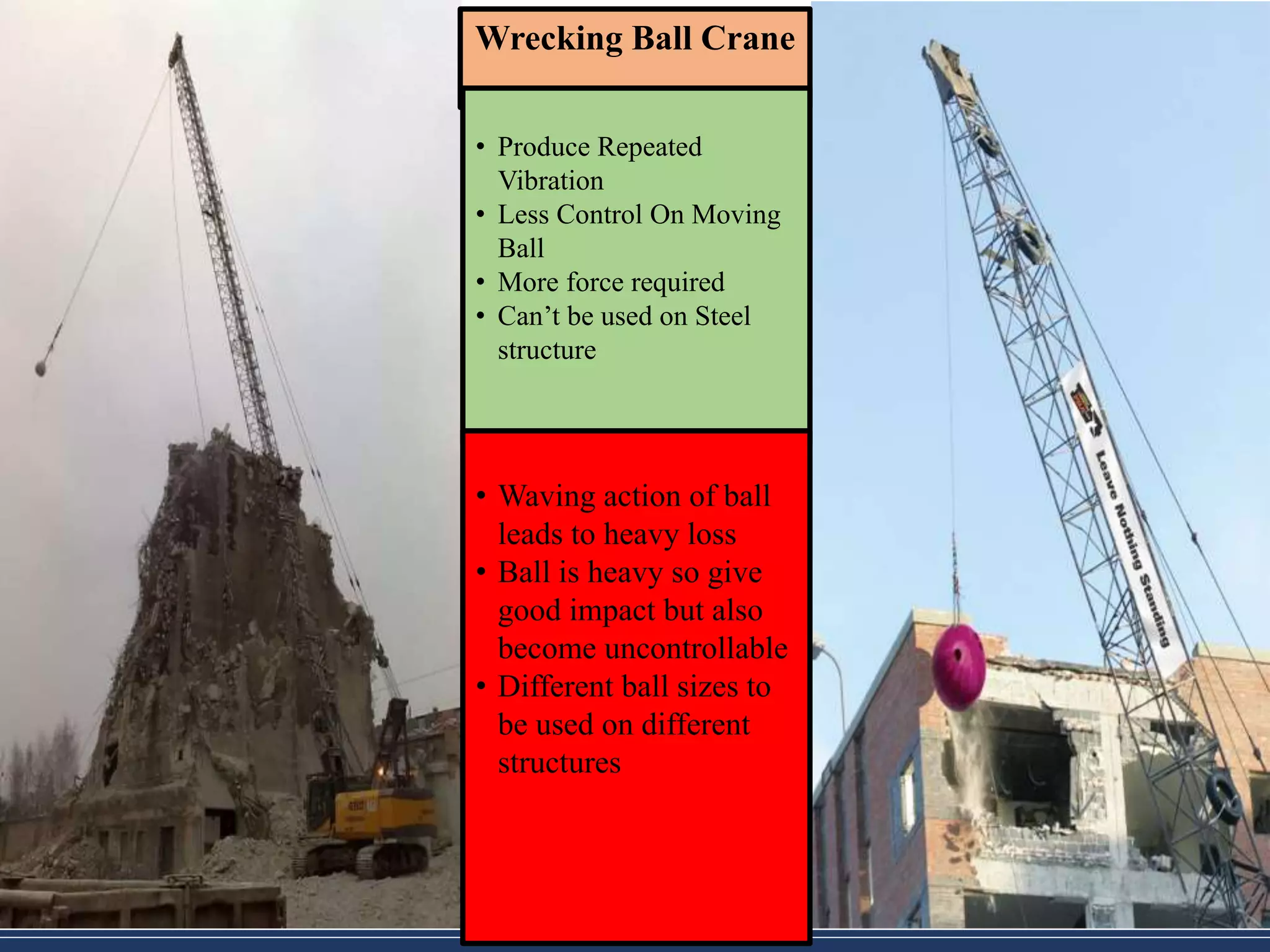

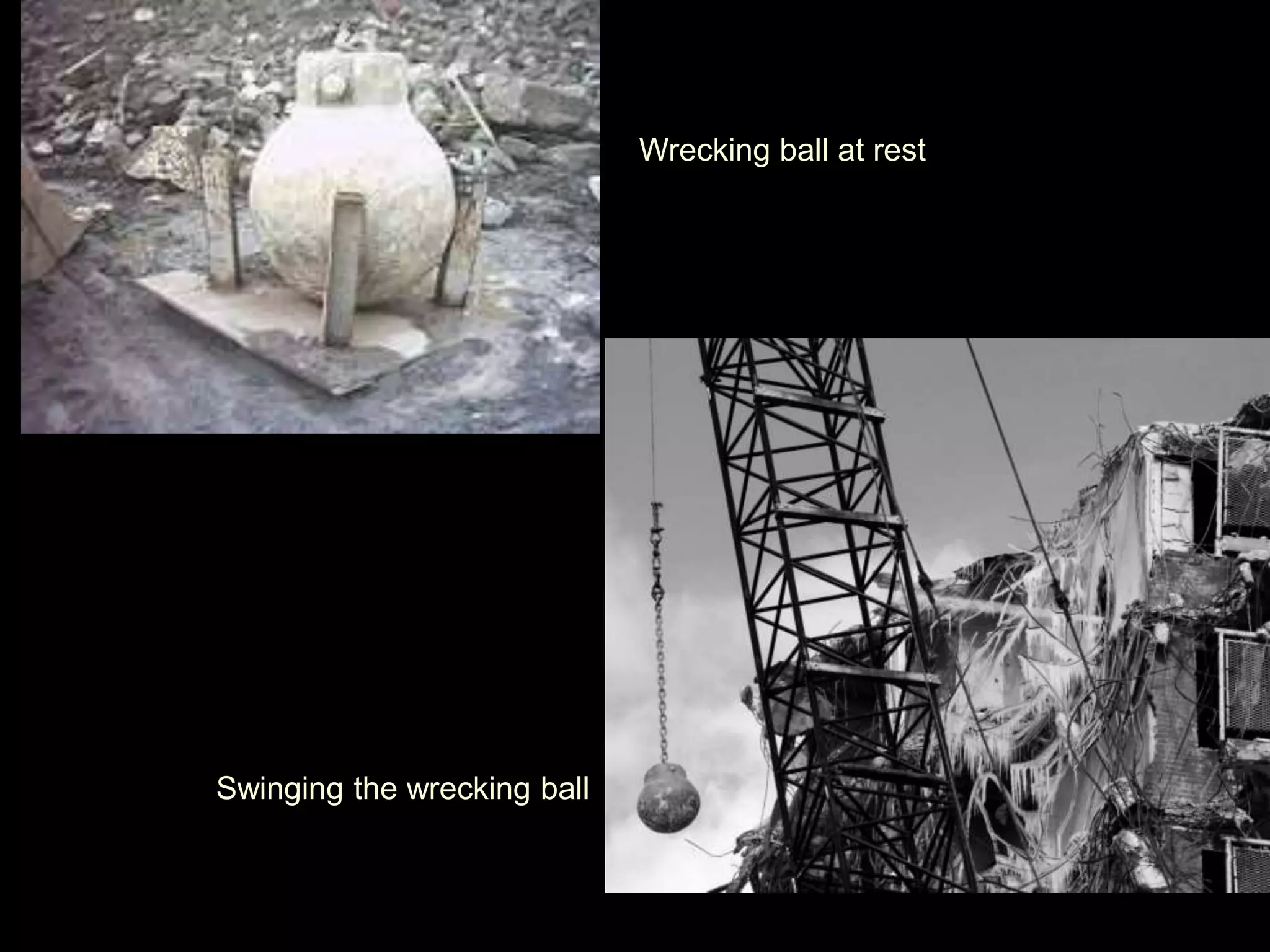

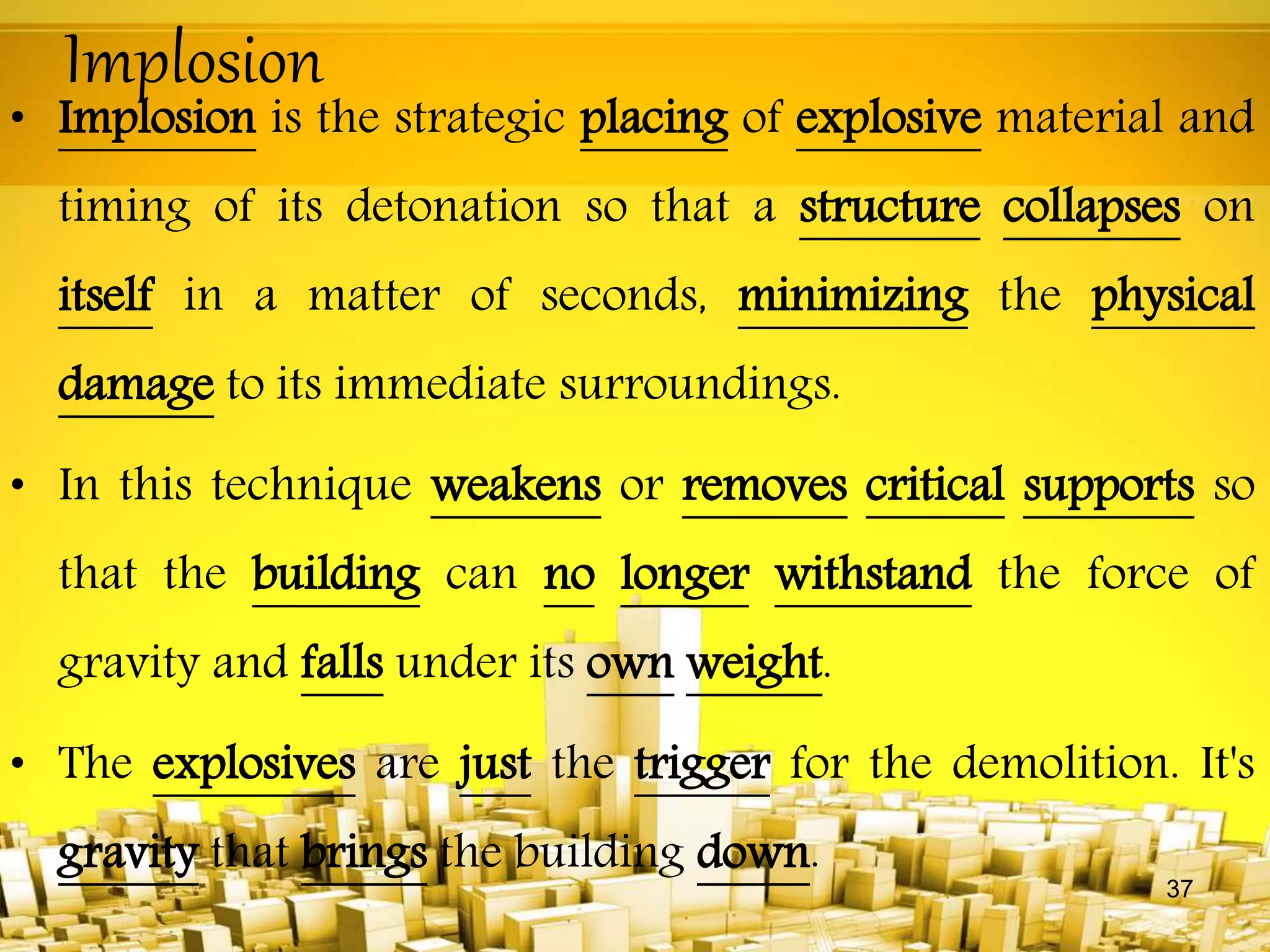

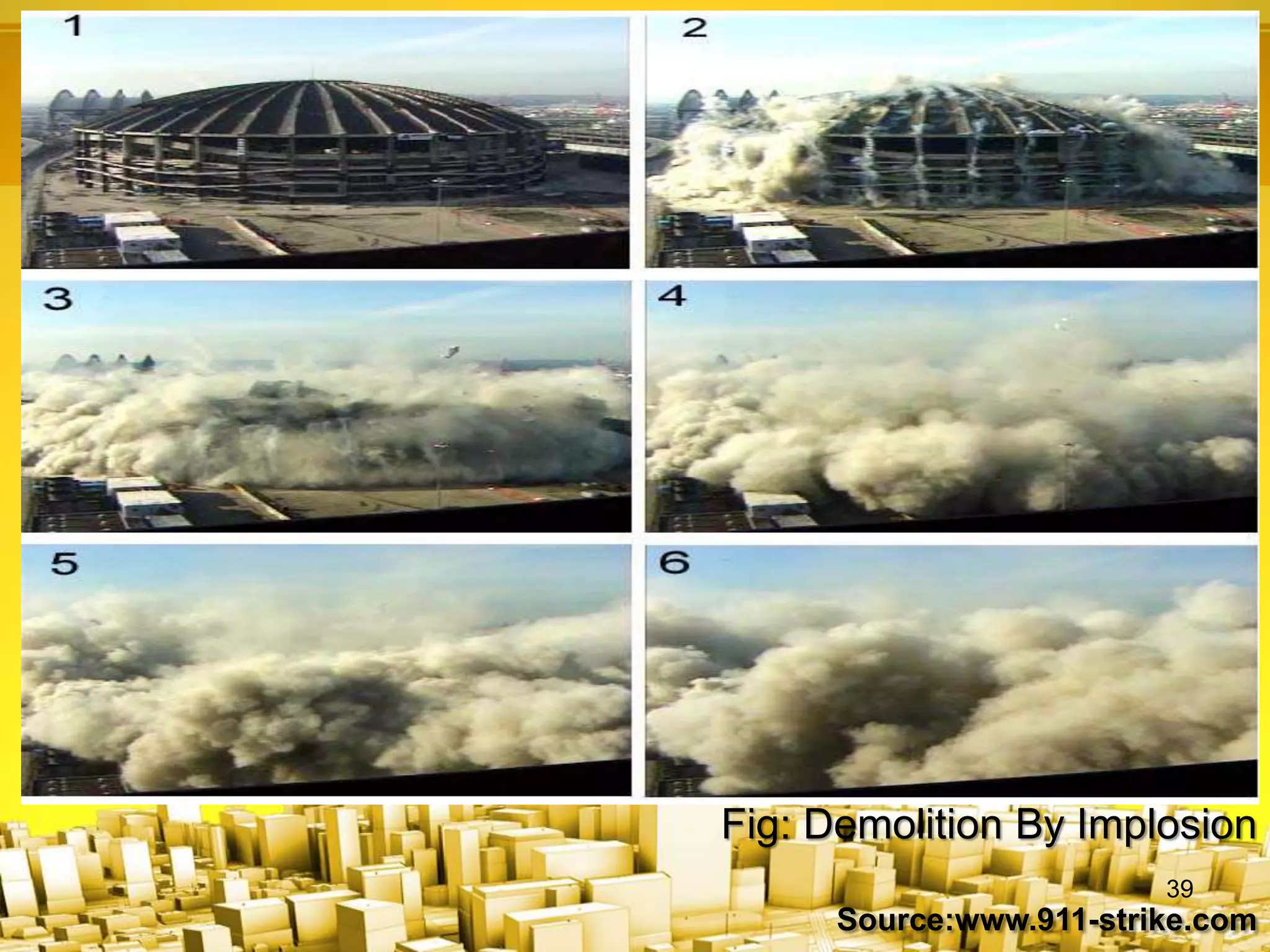

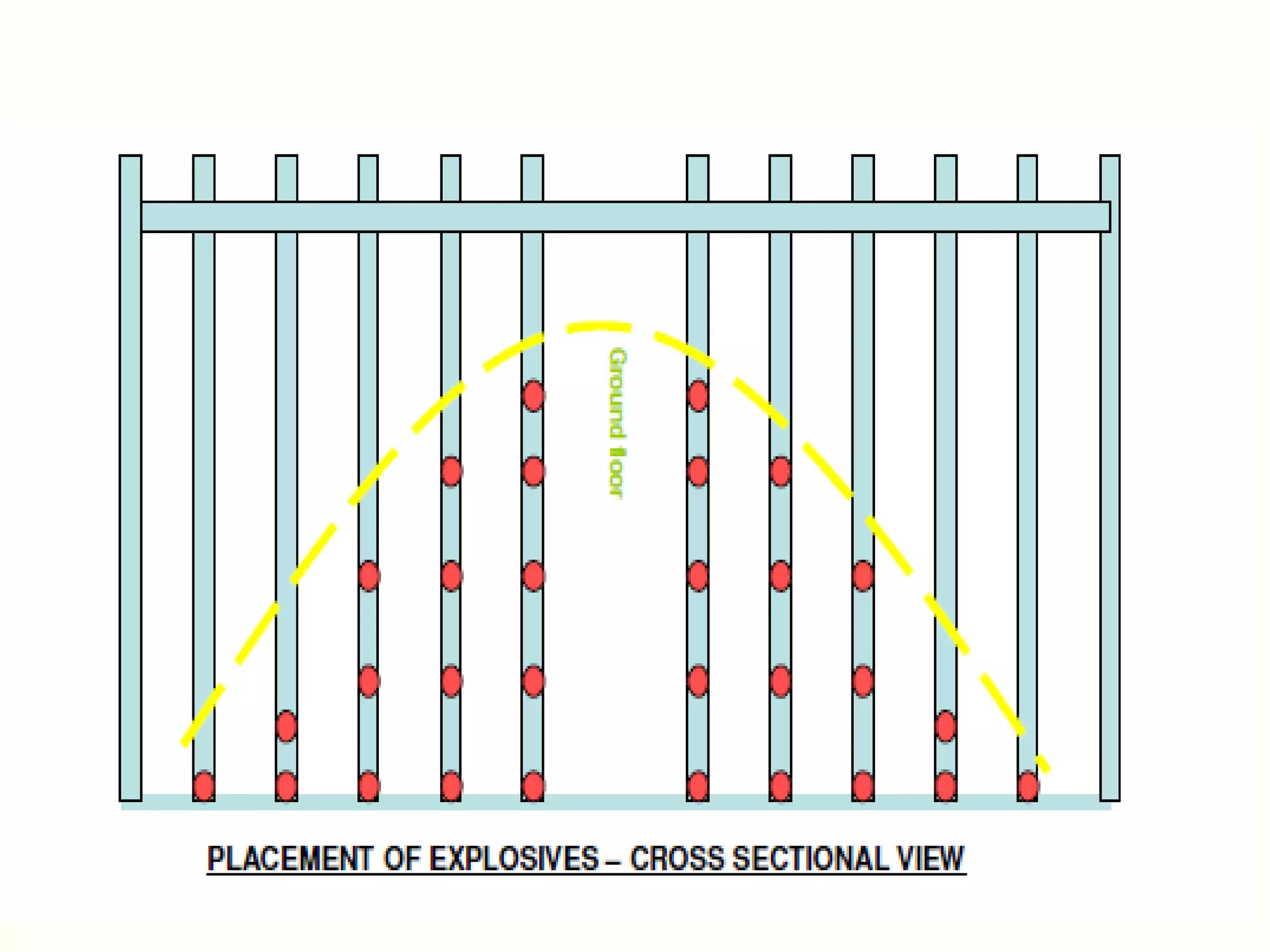

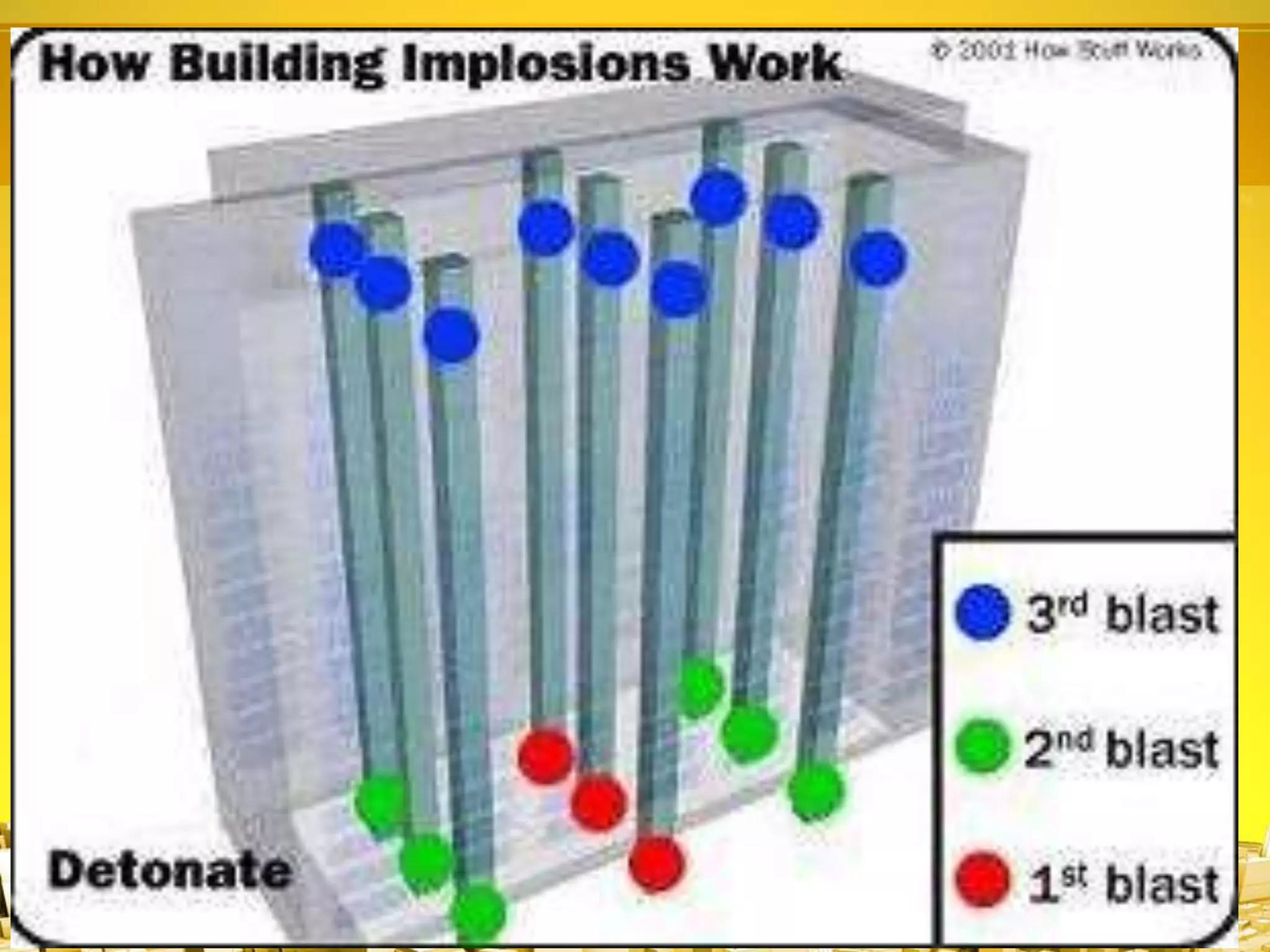

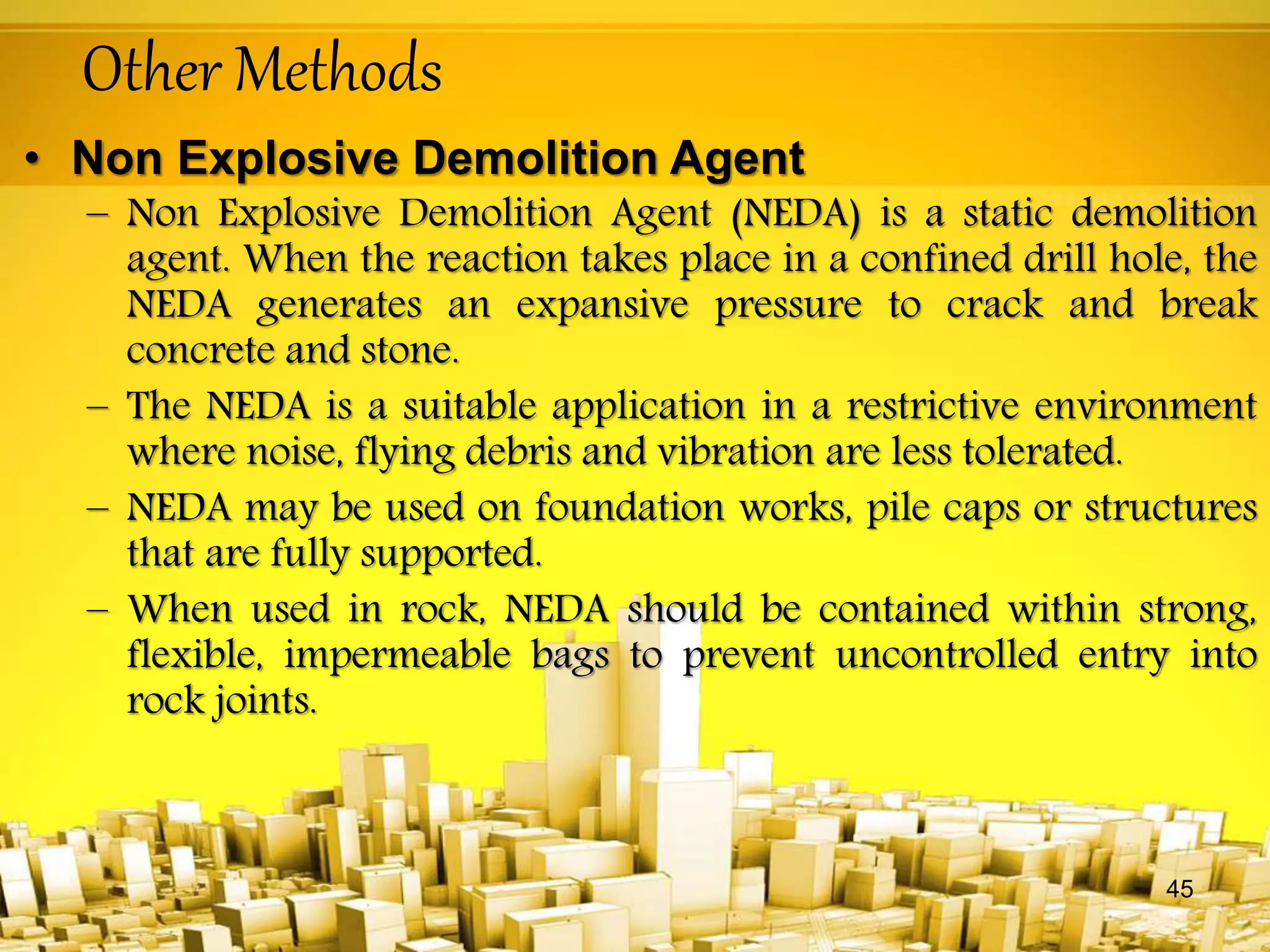

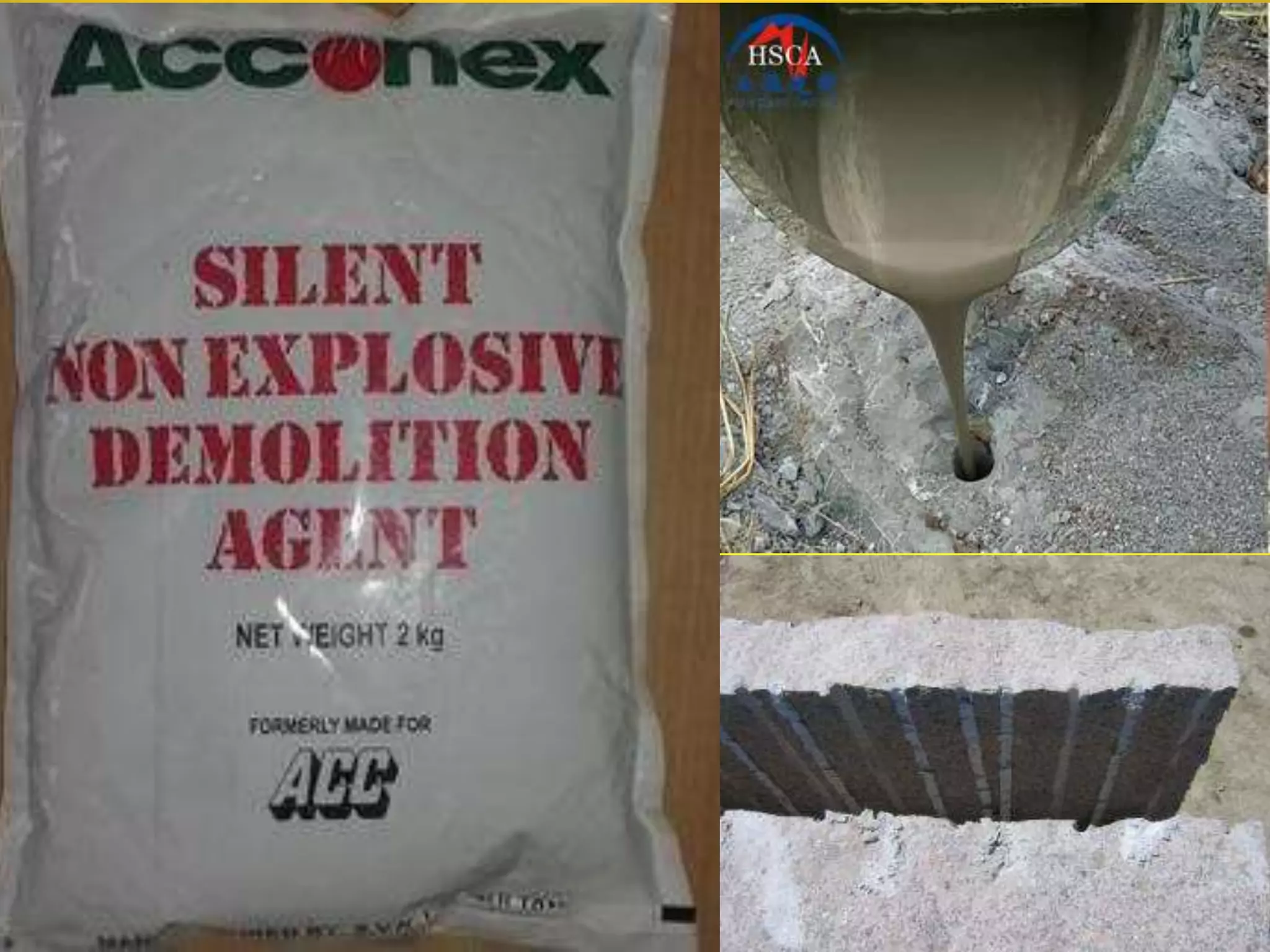

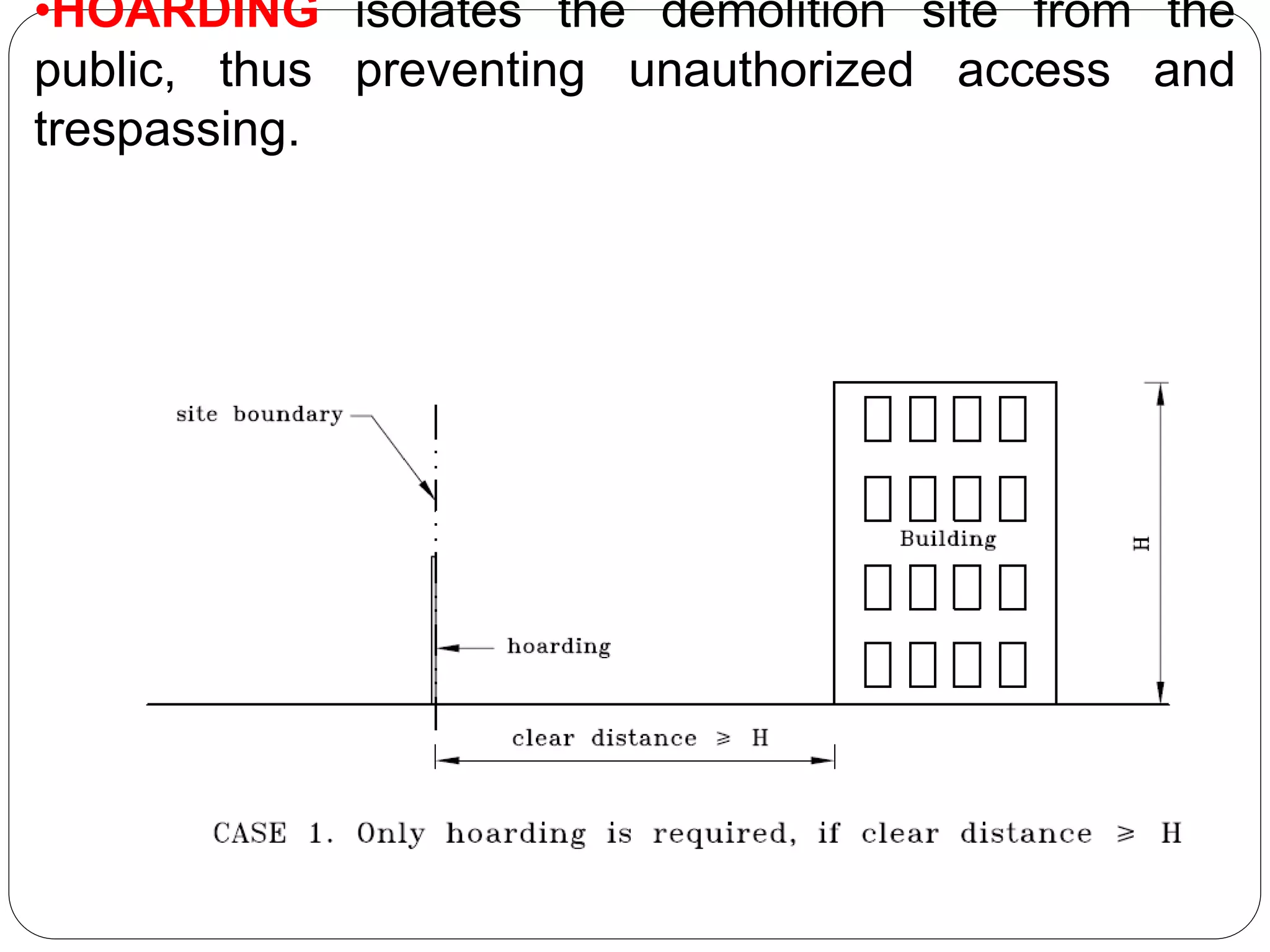

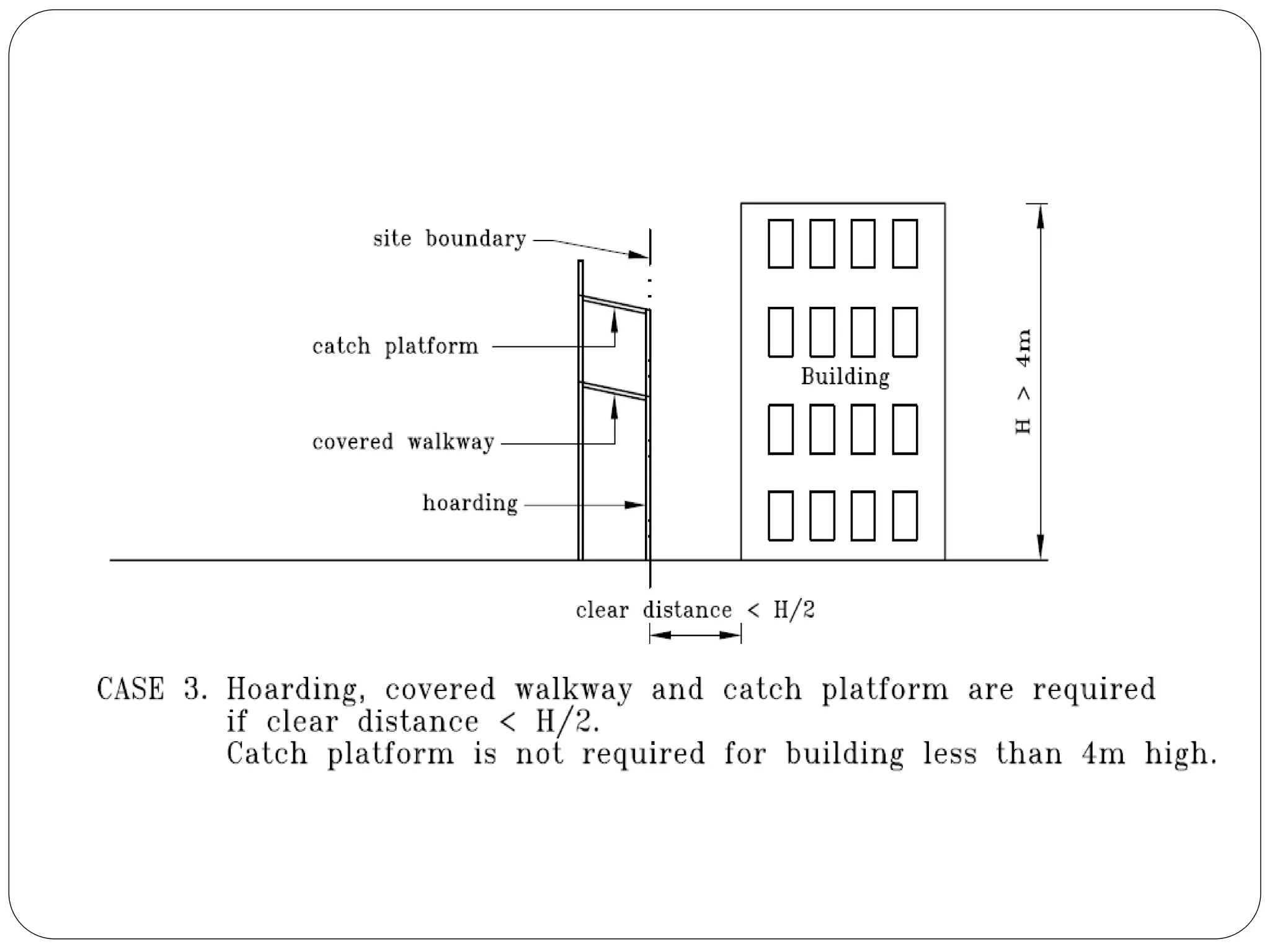

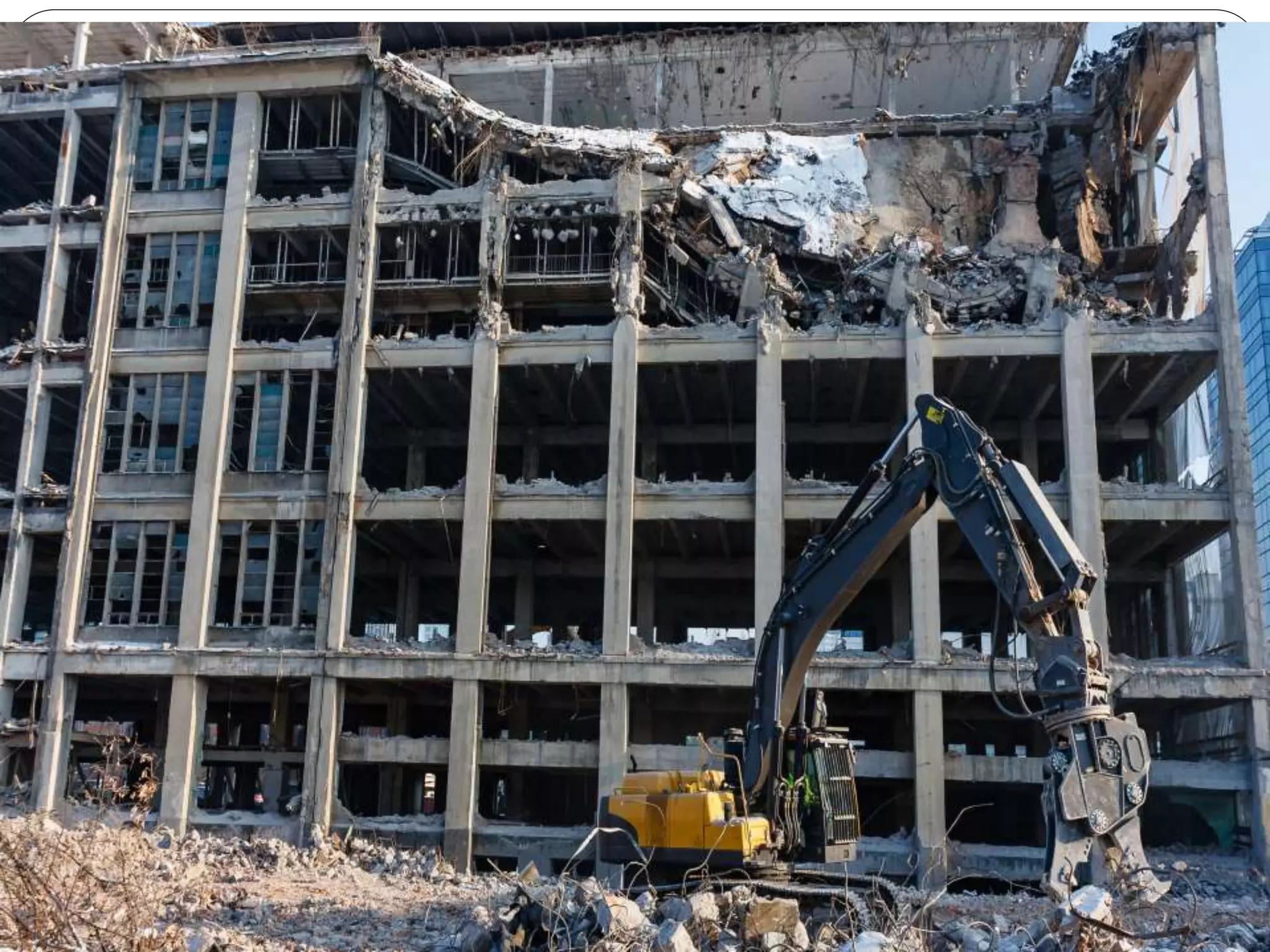

The document outlines the definitions, planning, types, and methods of demolition, emphasizing careful assessments of structures and surroundings before demolition begins. It details various techniques such as manual methods, pneumatic hammer, hydraulic crushers, wrecking balls, explosive demolition, implosion, and non-explosive agents, considering safety precautions throughout the process. Key considerations include utility management, hazardous material handling, and the necessity for approvals and supervision to ensure a safe demolition environment.