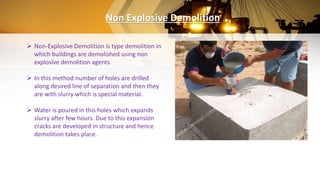

The document discusses the demolition of buildings. It describes various demolition methods including mechanical demolition using jackhammers and hydraulic breakers, and explosive demolition using explosives and implosions. It also covers non-explosive demolition using slurry, and deconstruction which is the selective dismantling of buildings. The document outlines important steps before demolition such as surveying, removing hazardous materials, preparing a demolition plan, and safety measures. Key steps after demolition include hauling and salvaging materials, disposing of waste, and planning new construction projects.