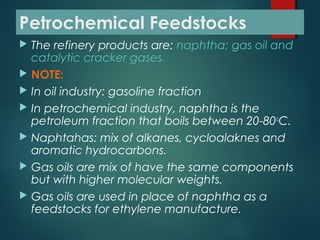

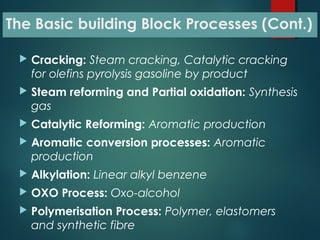

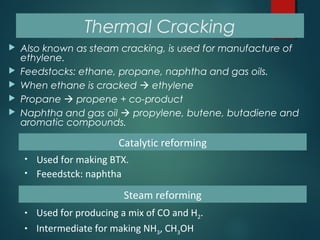

Petrochemical processes involve basic building block processes for manufacturing intermediates and products. Key petrochemical processes include thermal cracking, catalytic cracking, and steam reforming which produce olefins, synthesis gas, and aromatic compounds from petroleum feedstocks like naphtha and gas oil. Thermal cracking uses steam to crack ethane, propane and heavier hydrocarbons to produce ethylene, propylene and other products. Catalytic reforming uses naphtha to produce BTX aromatic compounds. Steam reforming produces a mixture of carbon monoxide and hydrogen from hydrocarbon feeds. Polymerization then links monomer molecules into long chains or networks to form plastics, fibers and other polymer products.