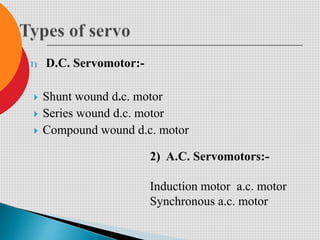

Servo motors have an output shaft that can be positioned to specific angular positions by sending a coded signal. They are constructed from basic DC motors with added gear reduction, a position sensor, and control circuitry. There are two main types - DC servo motors which are controlled by DC command signals applied directly to coils, and AC servo motors which are controlled by AC command signals. Servo motors offer advantages for sewing machines by allowing precise control of speed and silent operation when not engaged.