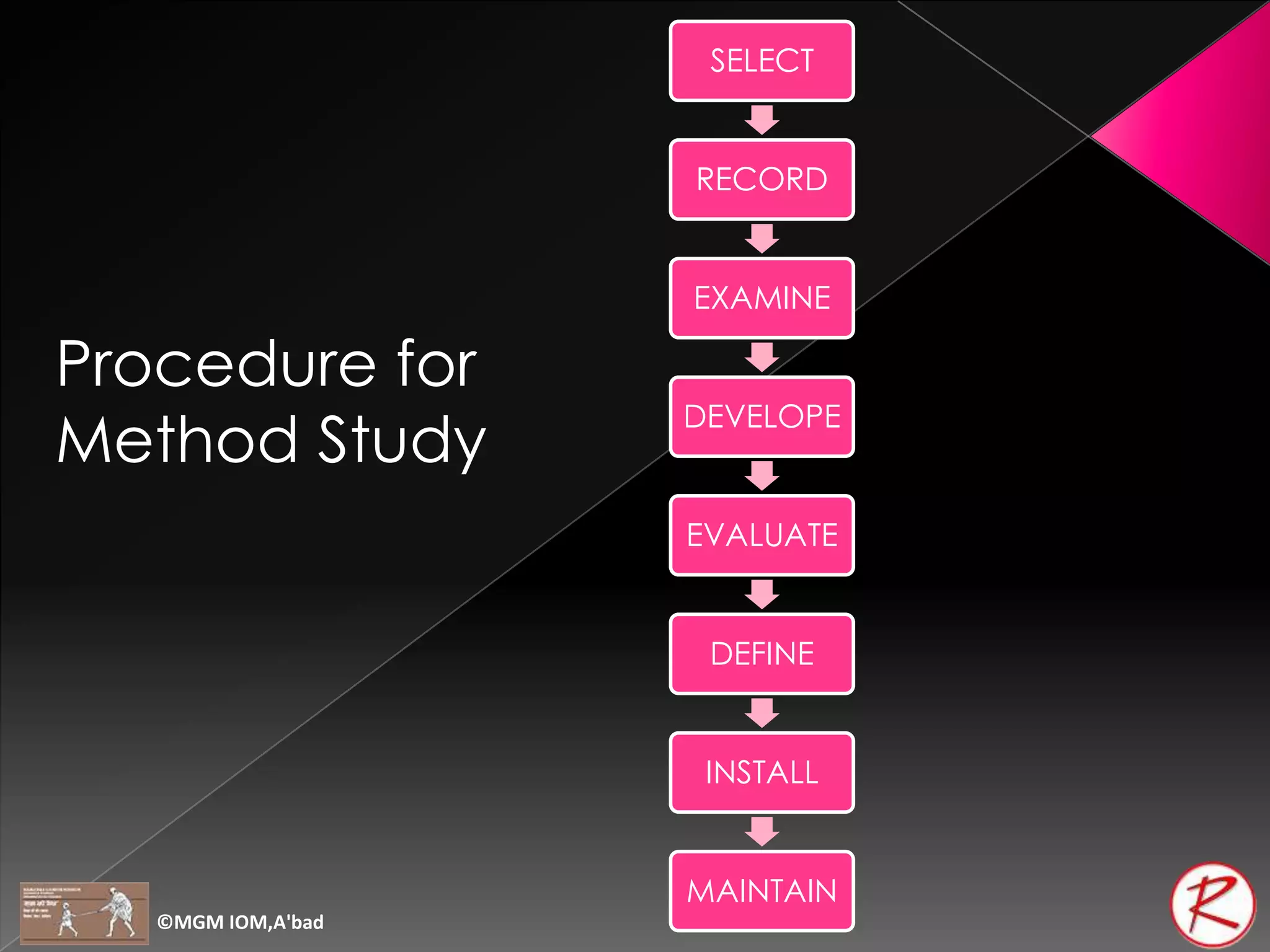

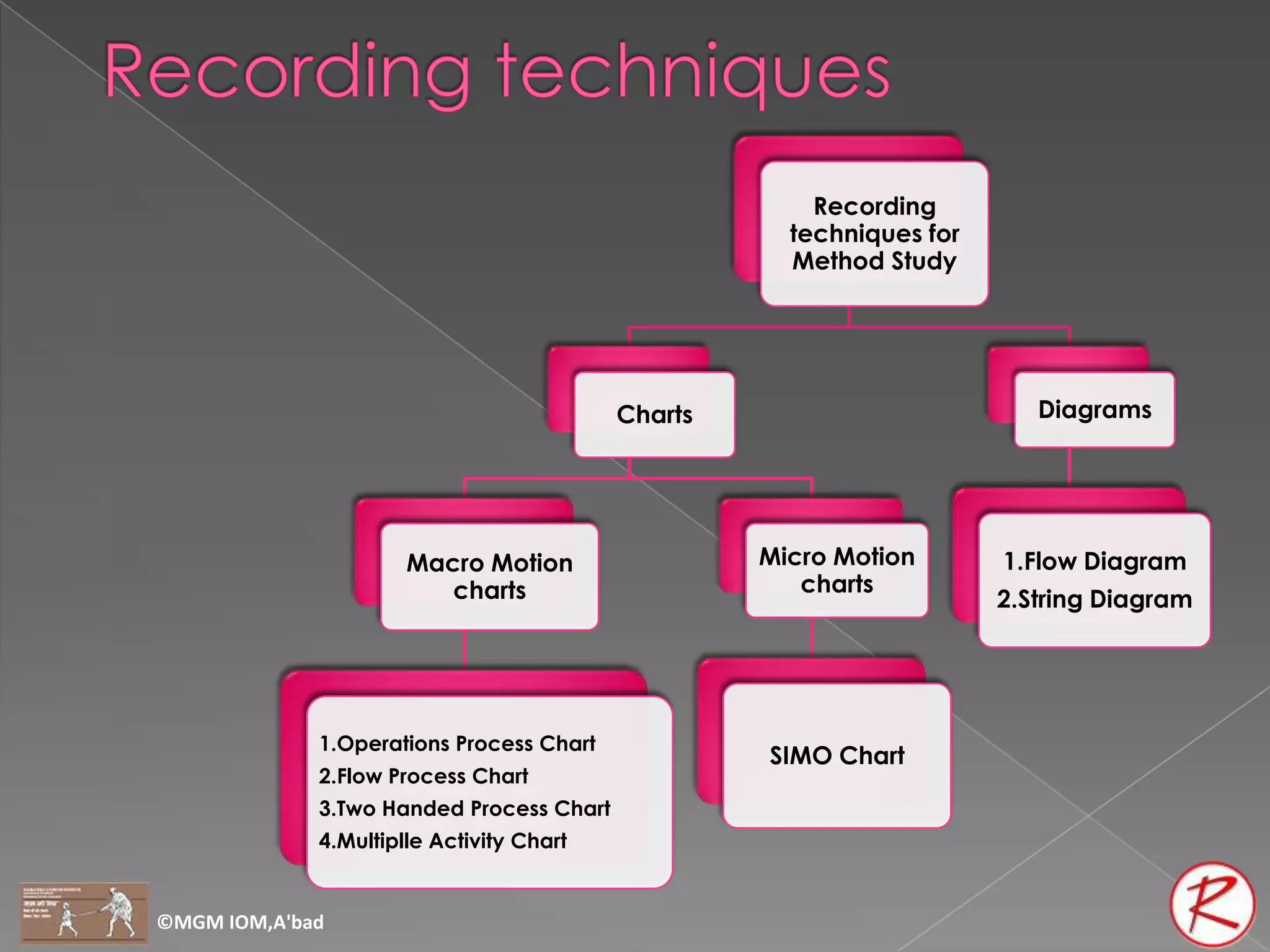

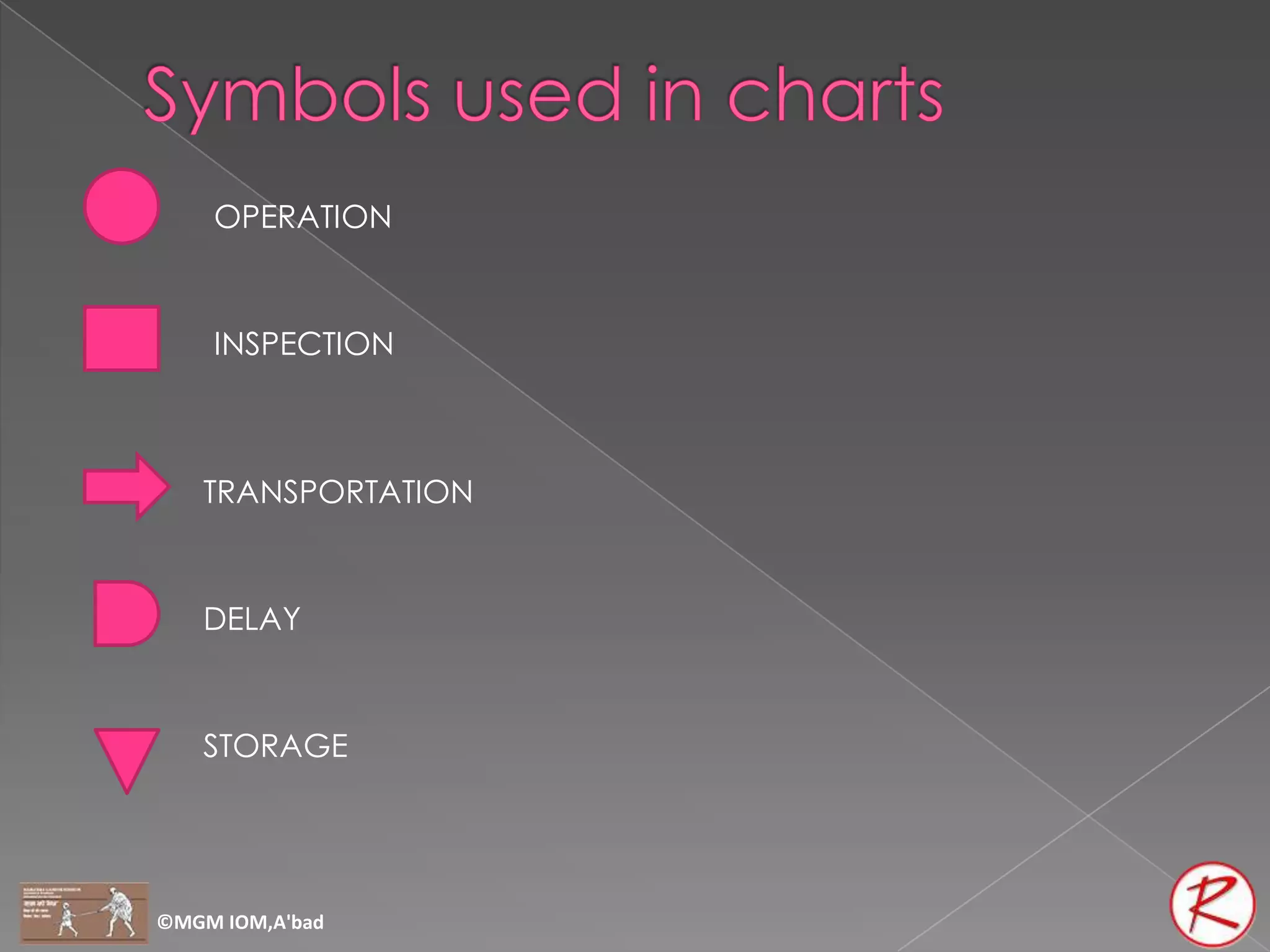

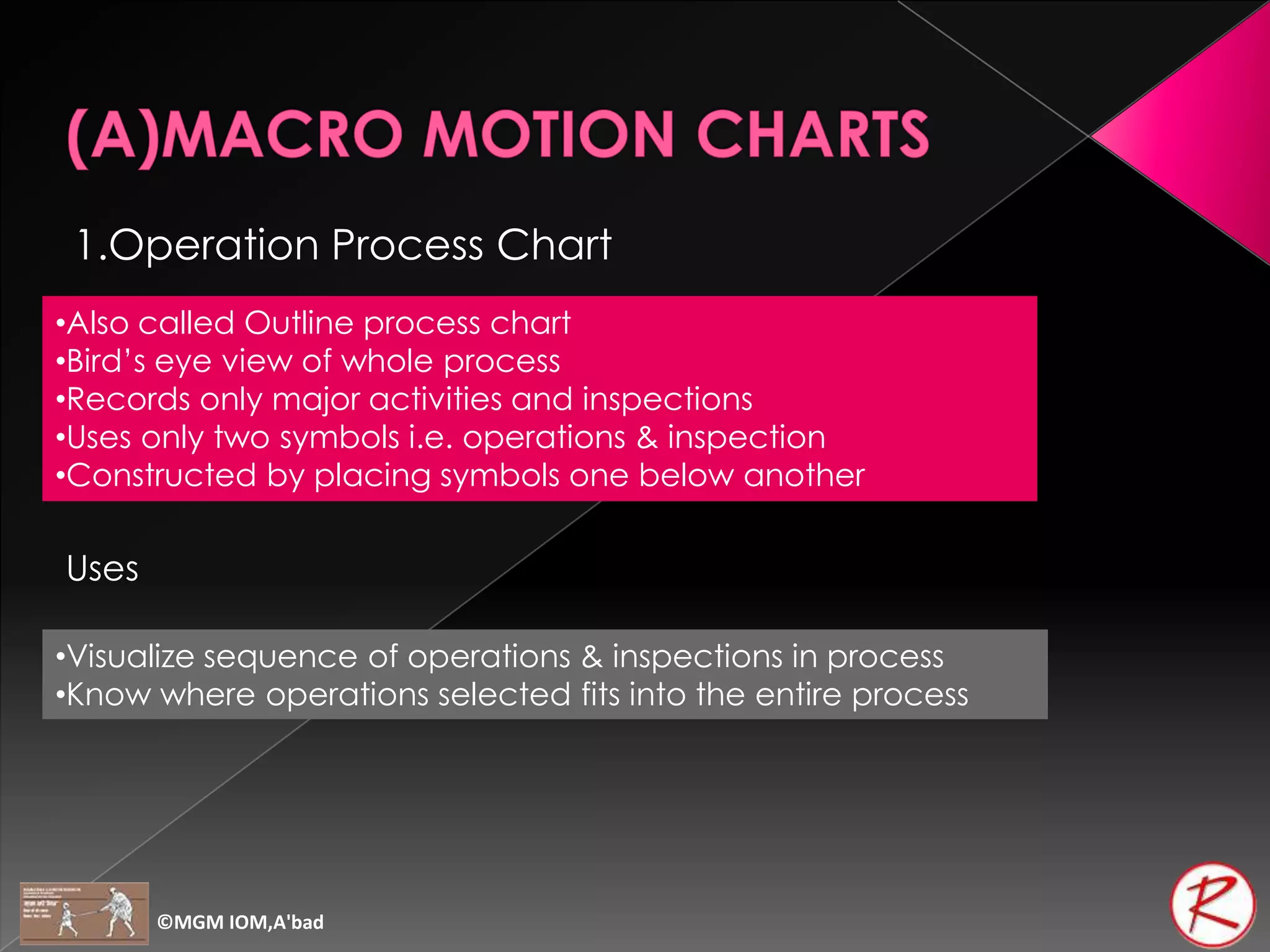

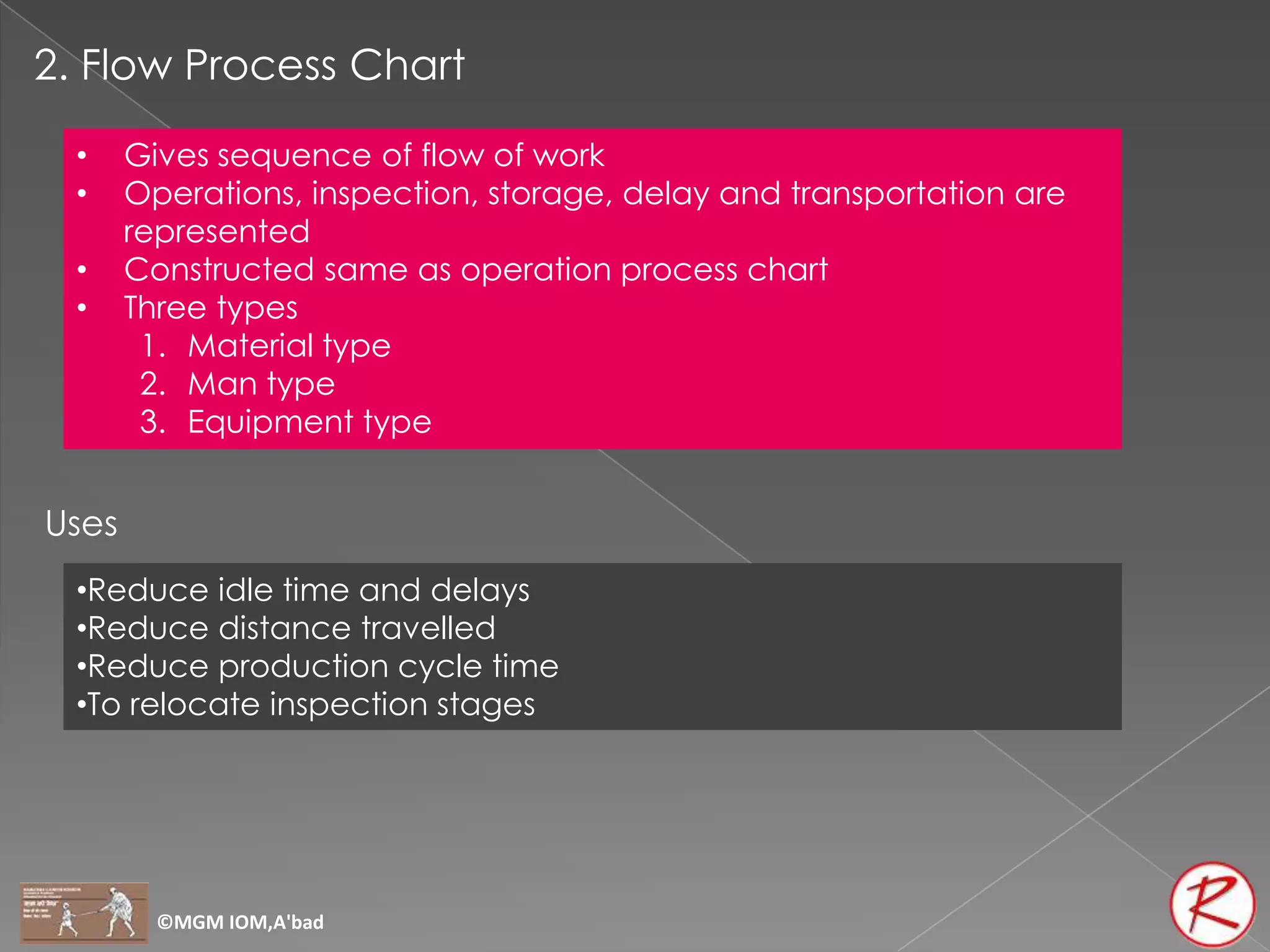

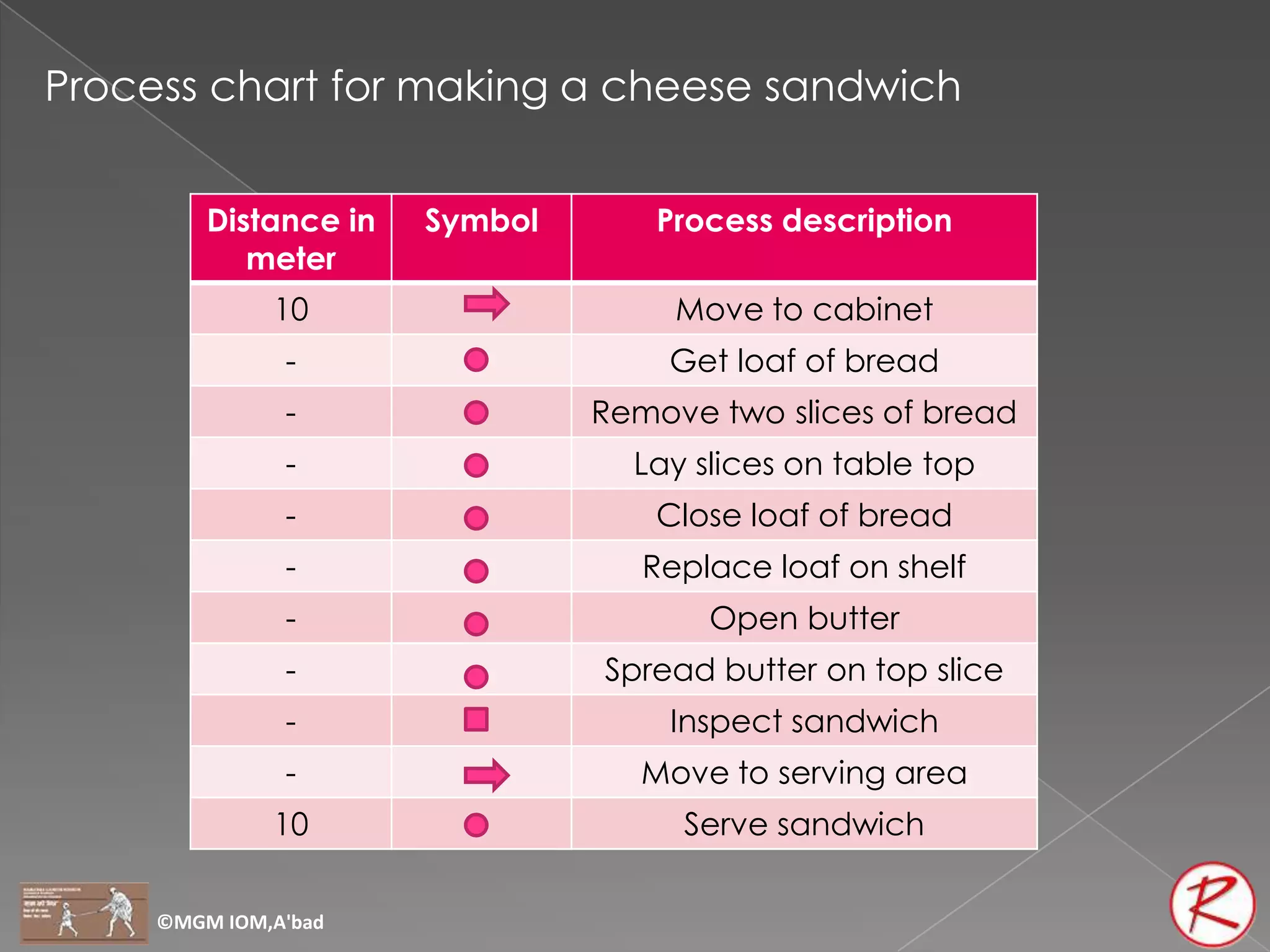

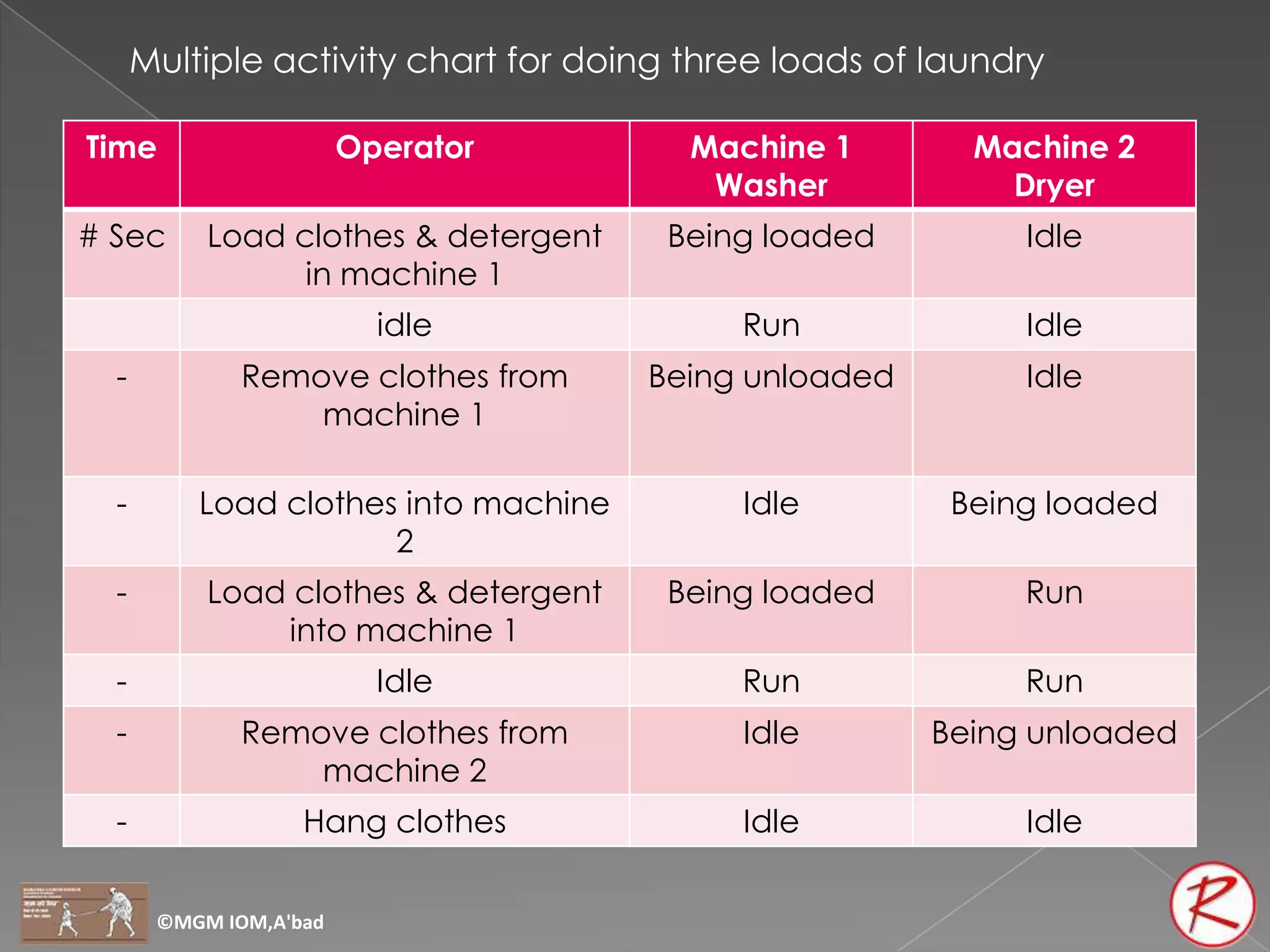

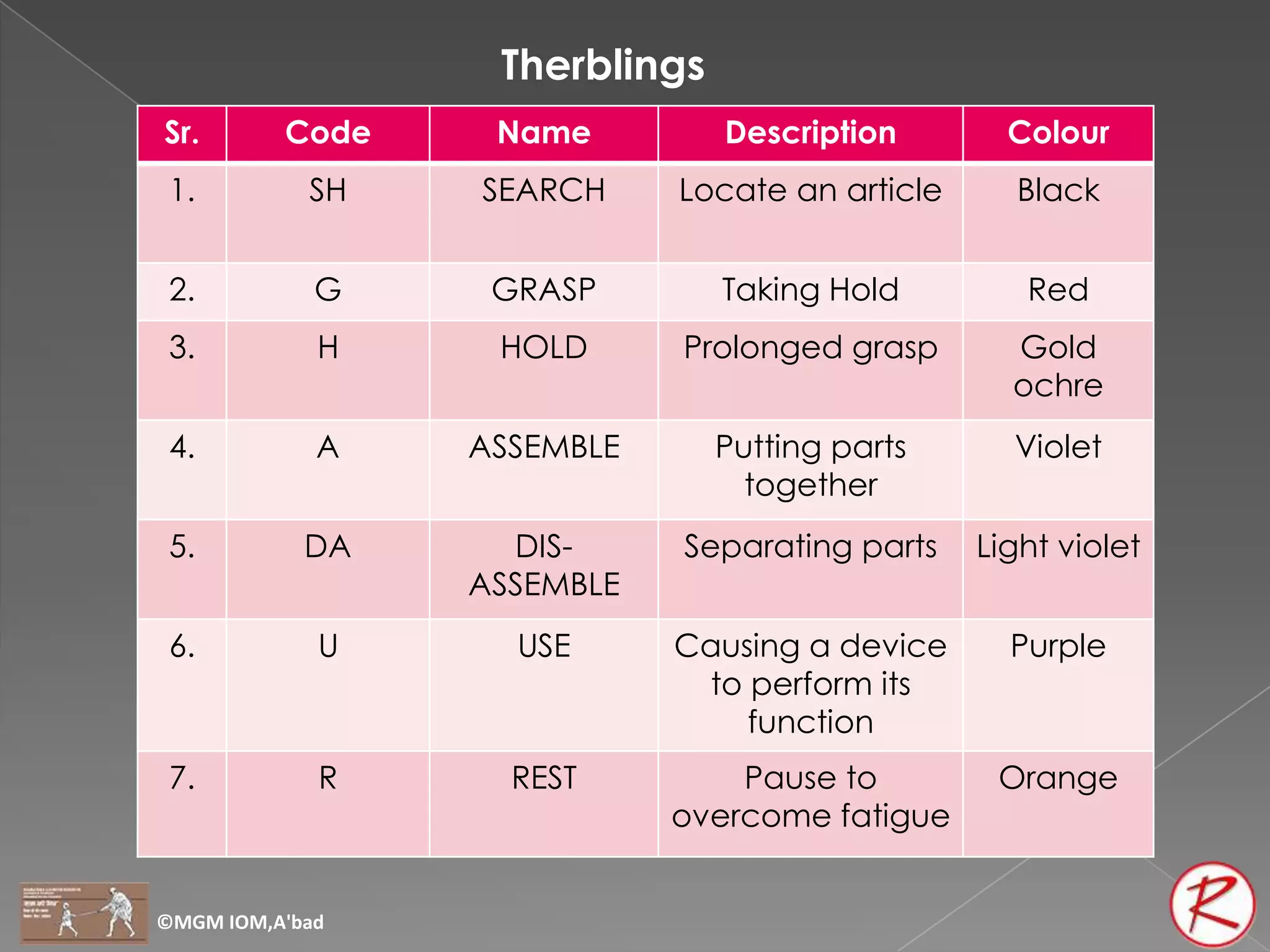

This document discusses methods engineering and method study. It describes method study as the systematic analysis and examination of work methods to develop more effective procedures. The key steps of method study include selecting processes to study, recording current methods, examining recordings for inefficiencies, developing improved methods, evaluating changes, defining new standards, installing changes, and maintaining improvements. A variety of charts and diagrams are used to record work including flow diagrams, string diagrams, process charts, and therblings analysis which divides tasks into elemental motions. The overall aim is to eliminate unnecessary steps and make processes more efficient.