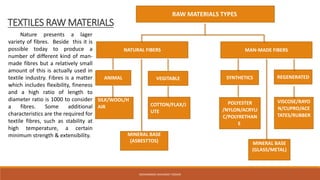

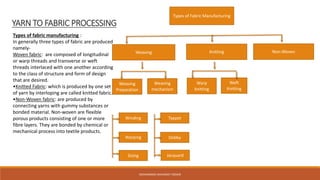

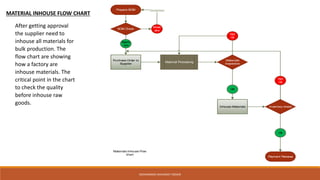

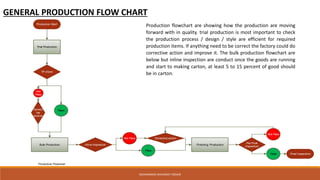

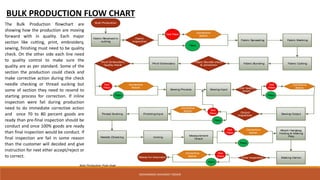

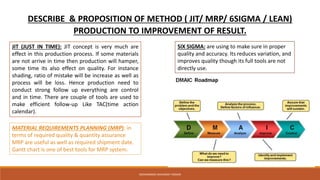

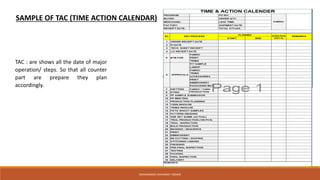

The document discusses the production flow from raw materials to garments. It begins with an overview of textile raw materials including natural and man-made fibers used. It then outlines the processes of yarn manufacturing including spinning and fabric manufacturing through weaving, knitting, and non-woven methods. The document details the various departments involved in garments manufacturing from merchandising to quality control. It provides process flow charts for sampling approval, material in-house flow, general production, bulk production, and order progress tracking. Finally, it discusses approaches like JIT, MRP, Six Sigma and Lean that can be used to improve production results.