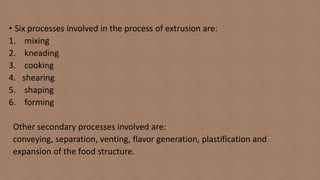

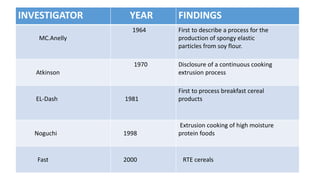

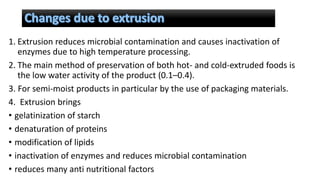

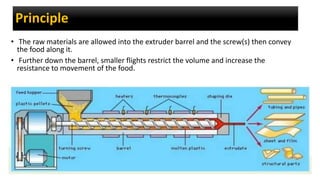

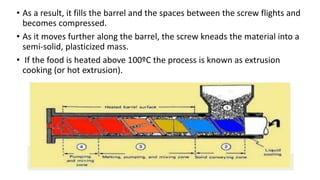

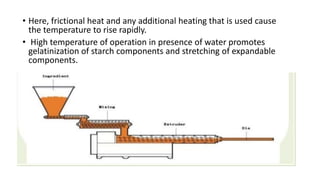

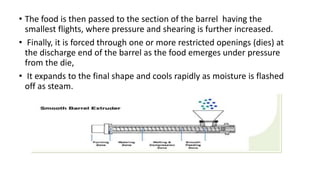

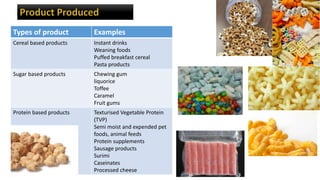

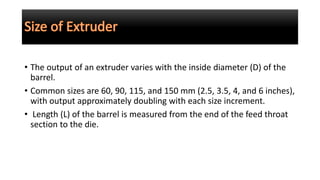

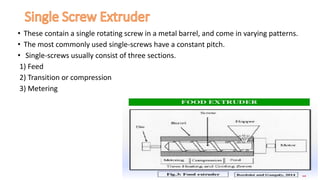

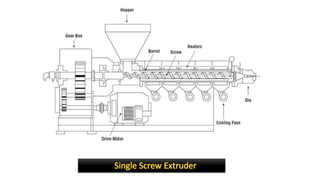

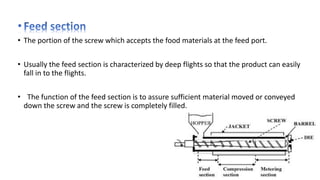

This document discusses extrusion, an important food processing technique. It defines extrusion as pushing material through an orifice or die using a piston or screw. Extruders contain three main sections - feeding, compression, and metering. They allow for continuous high-temperature short-time processing to cook, shape, and form foods. Extrusion is versatile and can produce a variety of product types from cereals to protein products in a cost-effective manner.