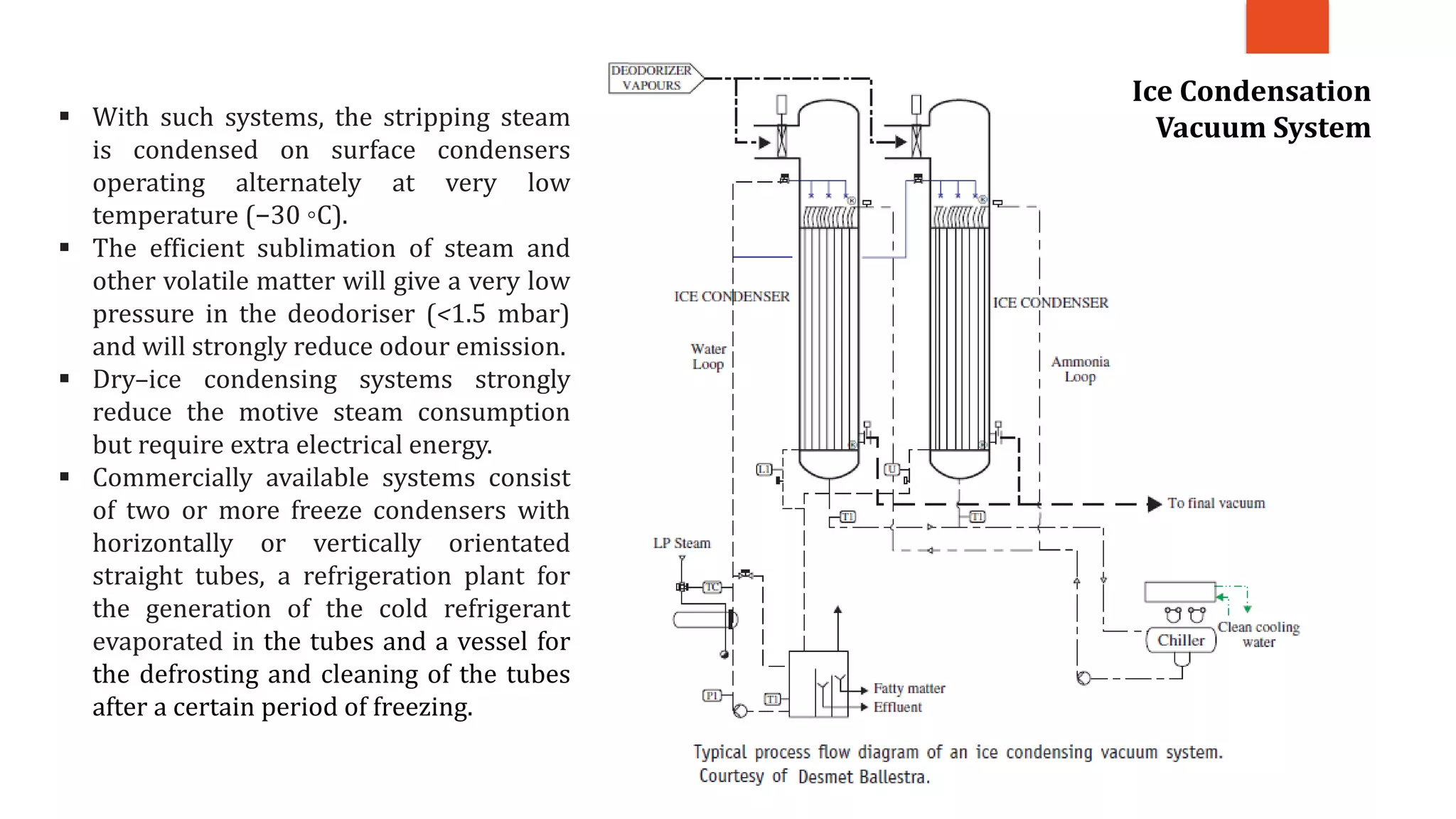

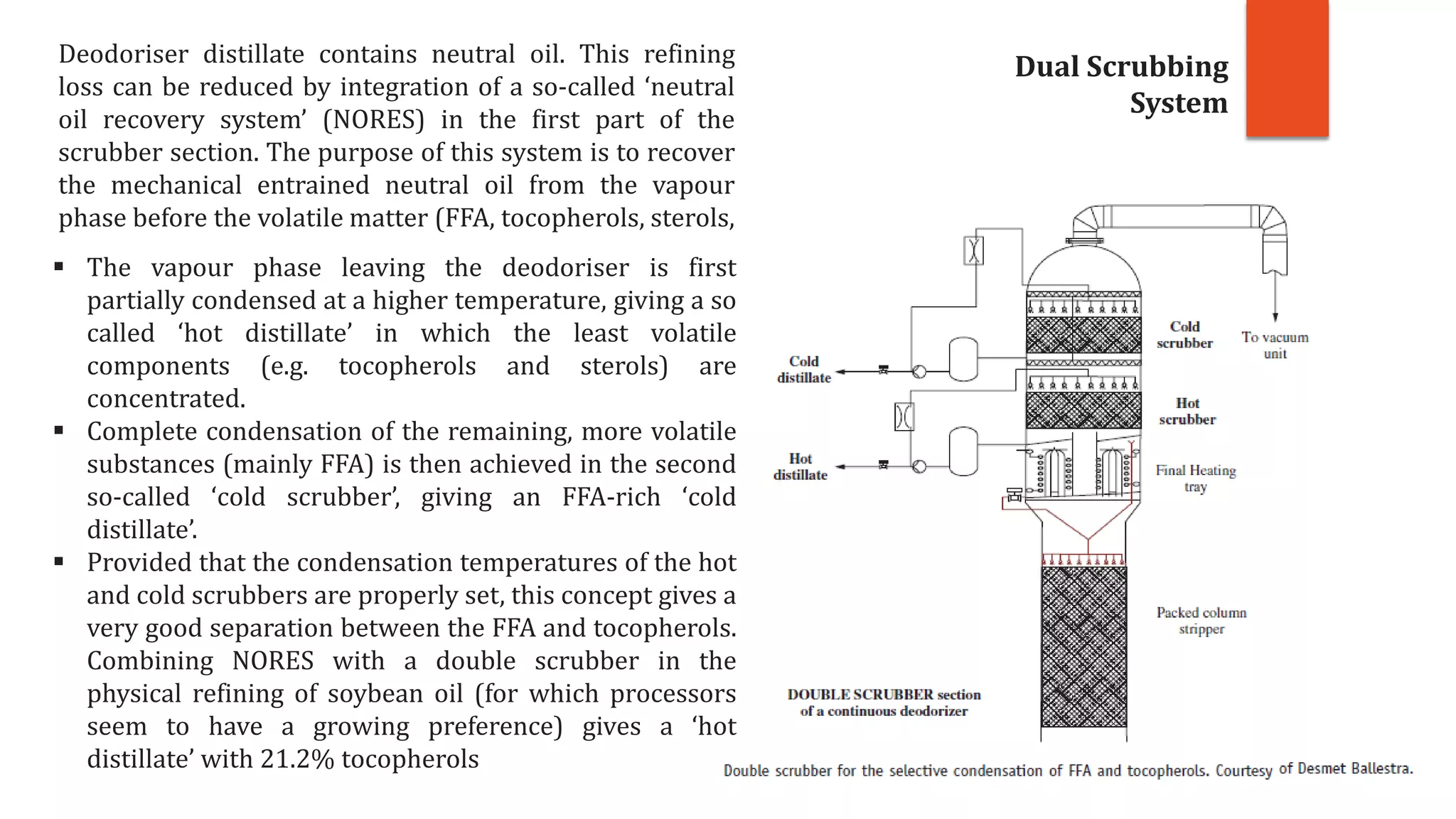

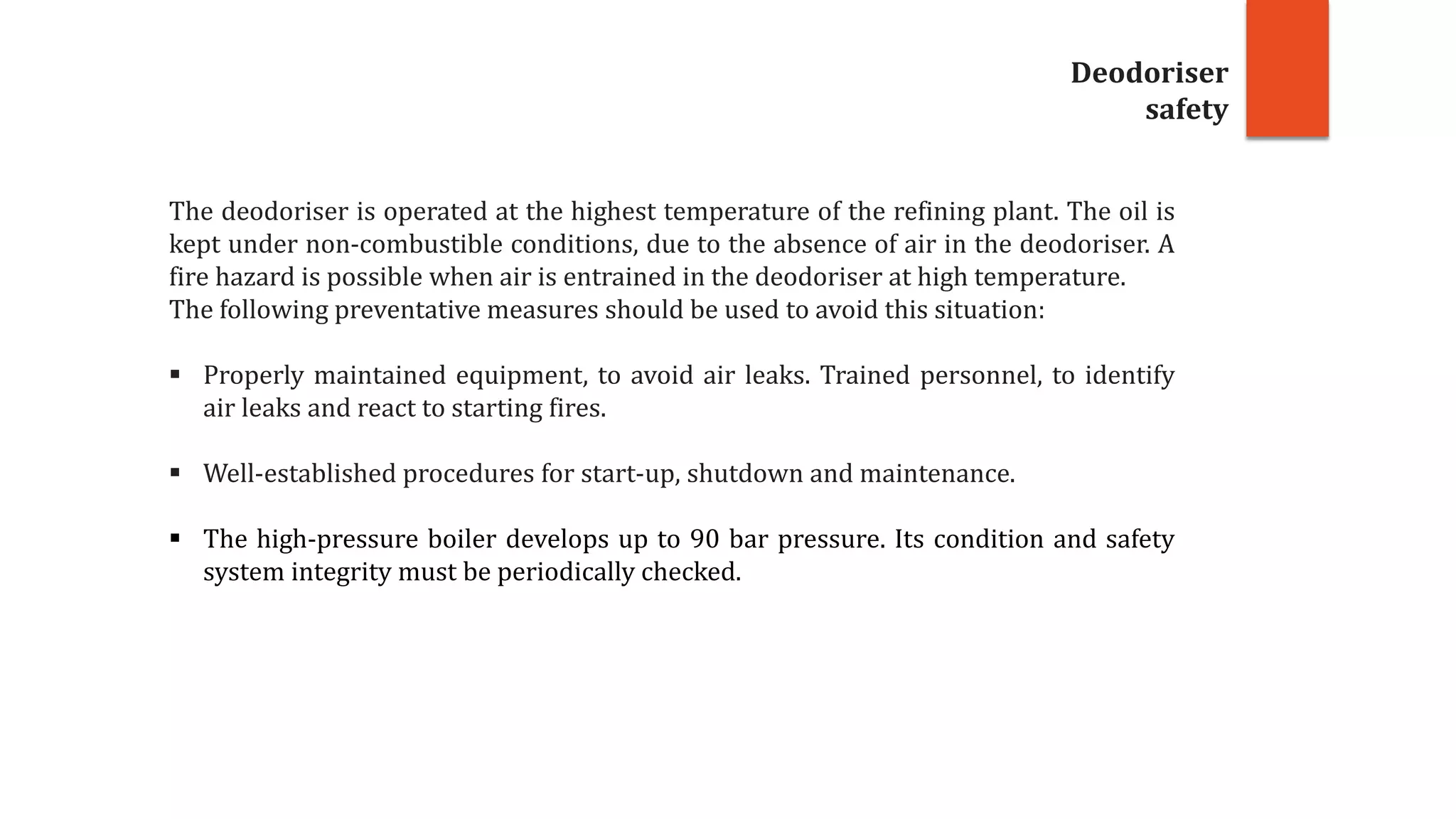

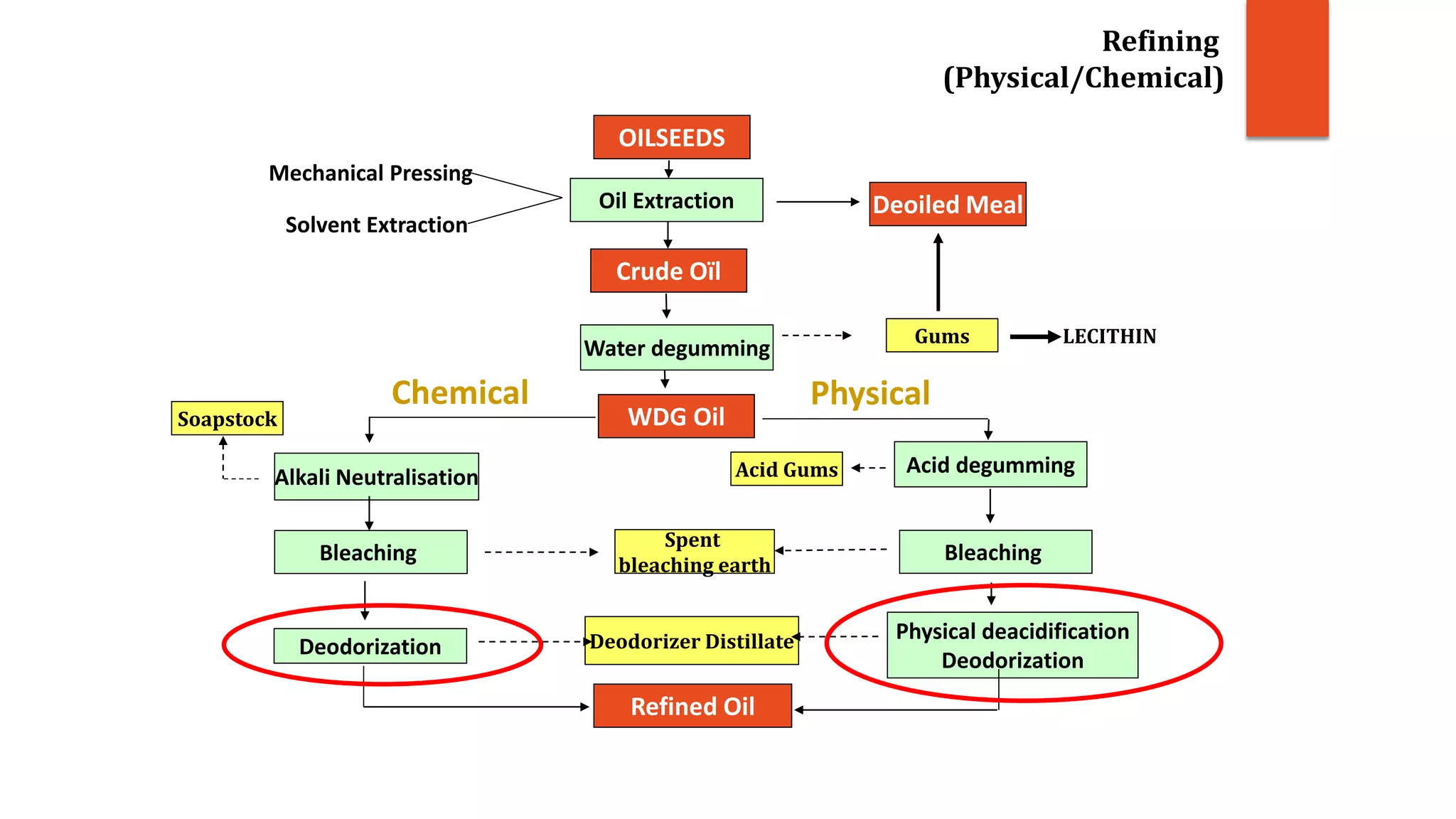

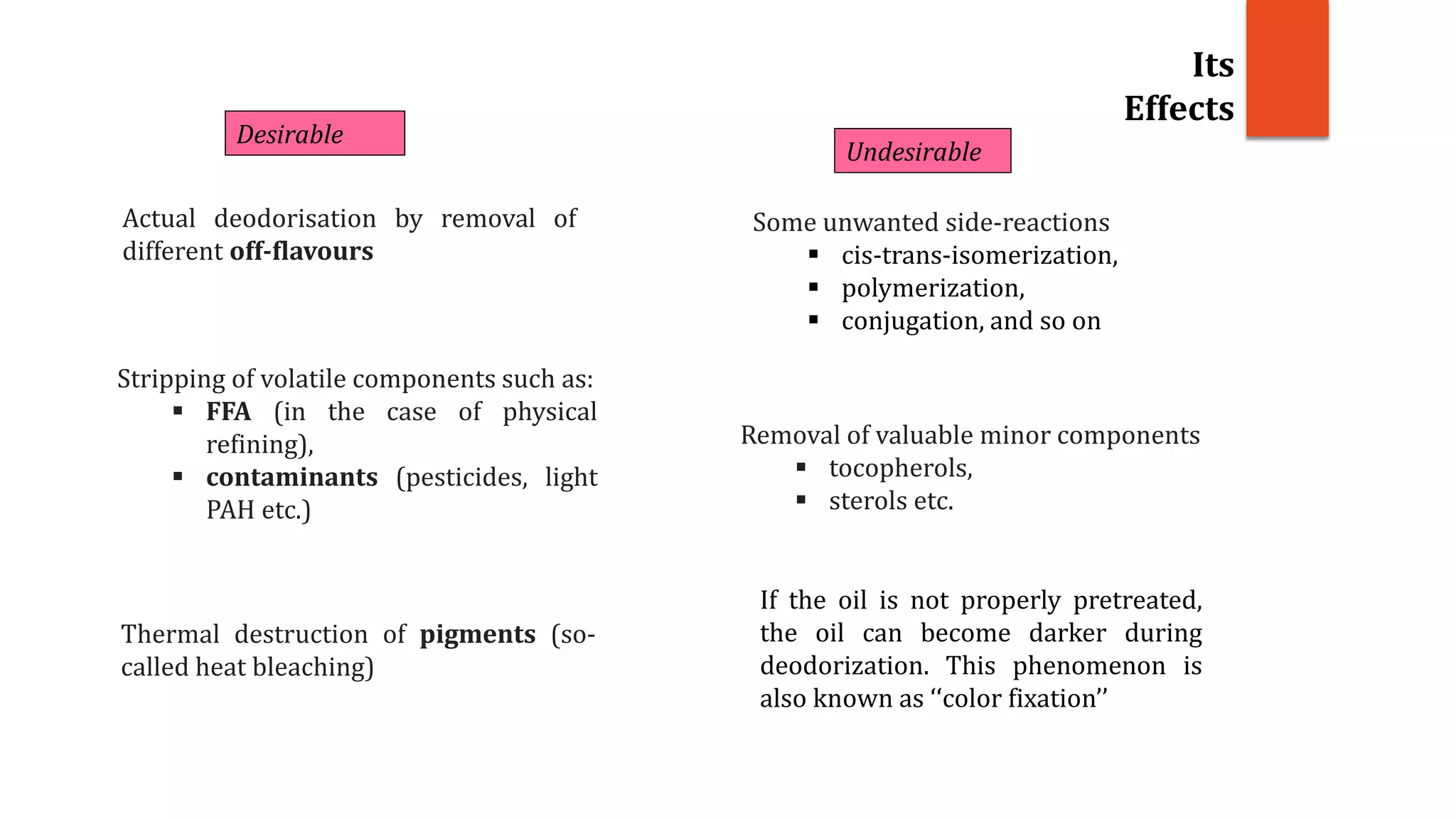

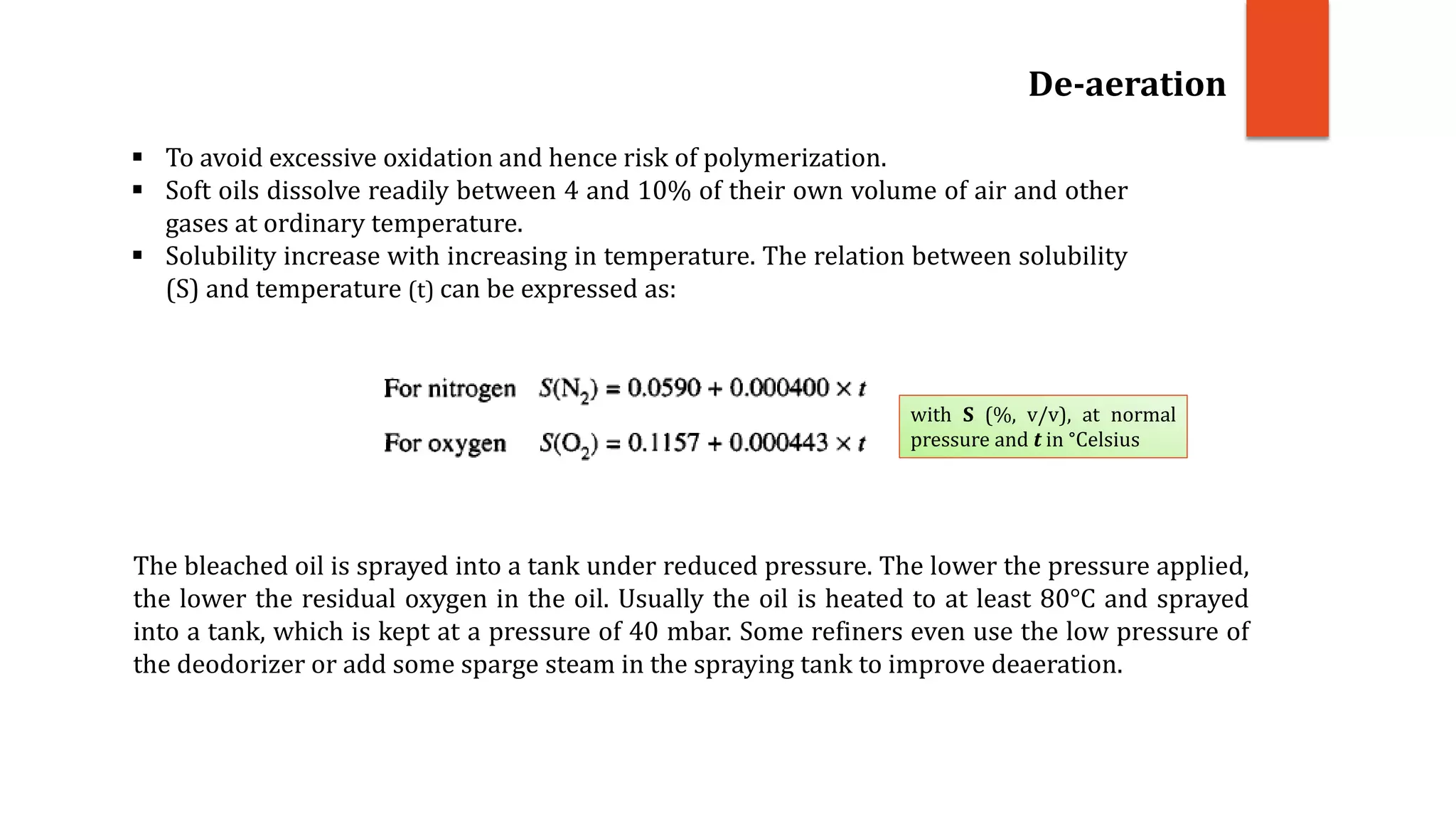

This document provides an overview of the deodorization process, which is the final stage in edible oil refining. It aims to remove odor-causing compounds and other undesirable elements. The key points covered include:

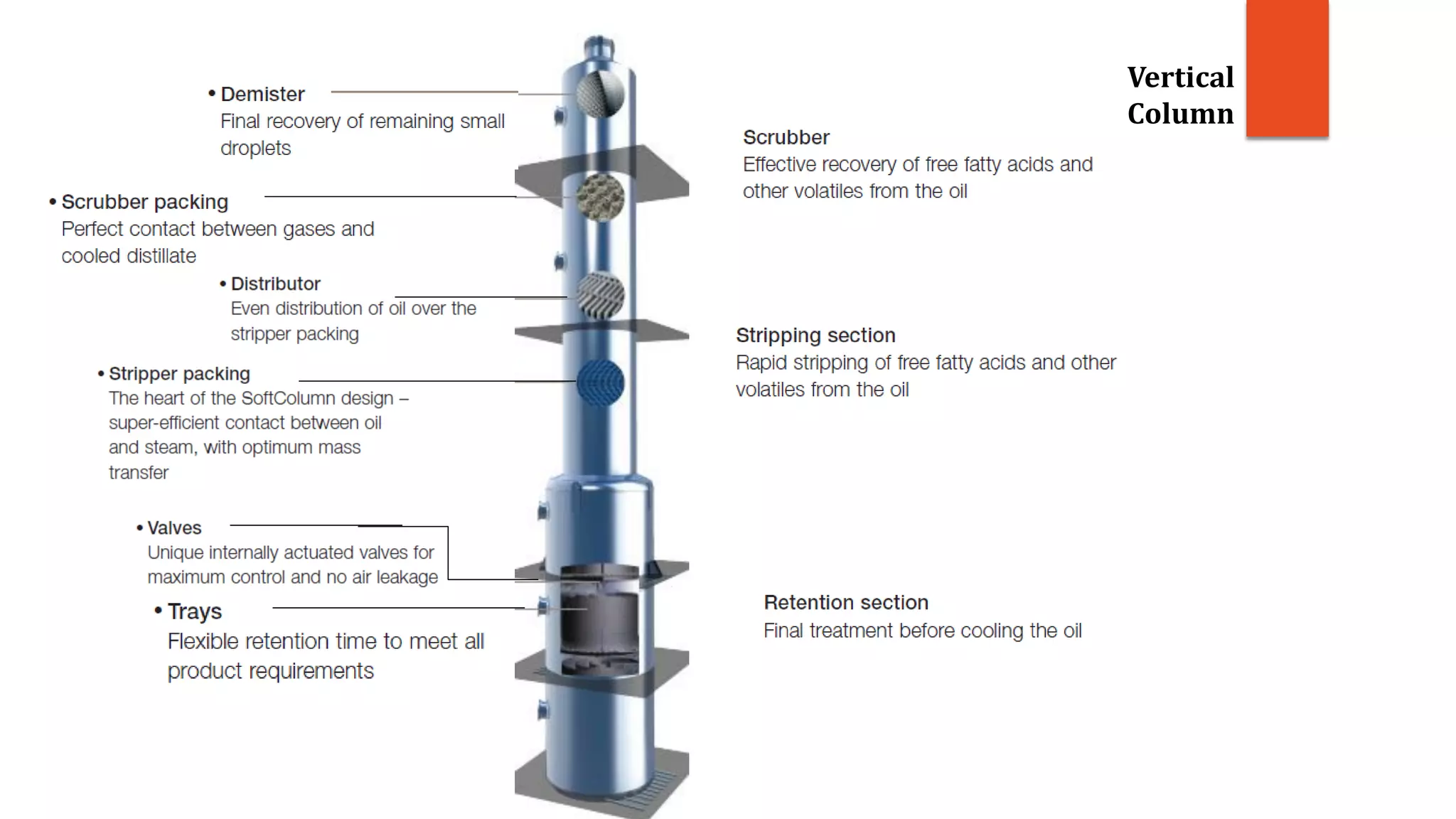

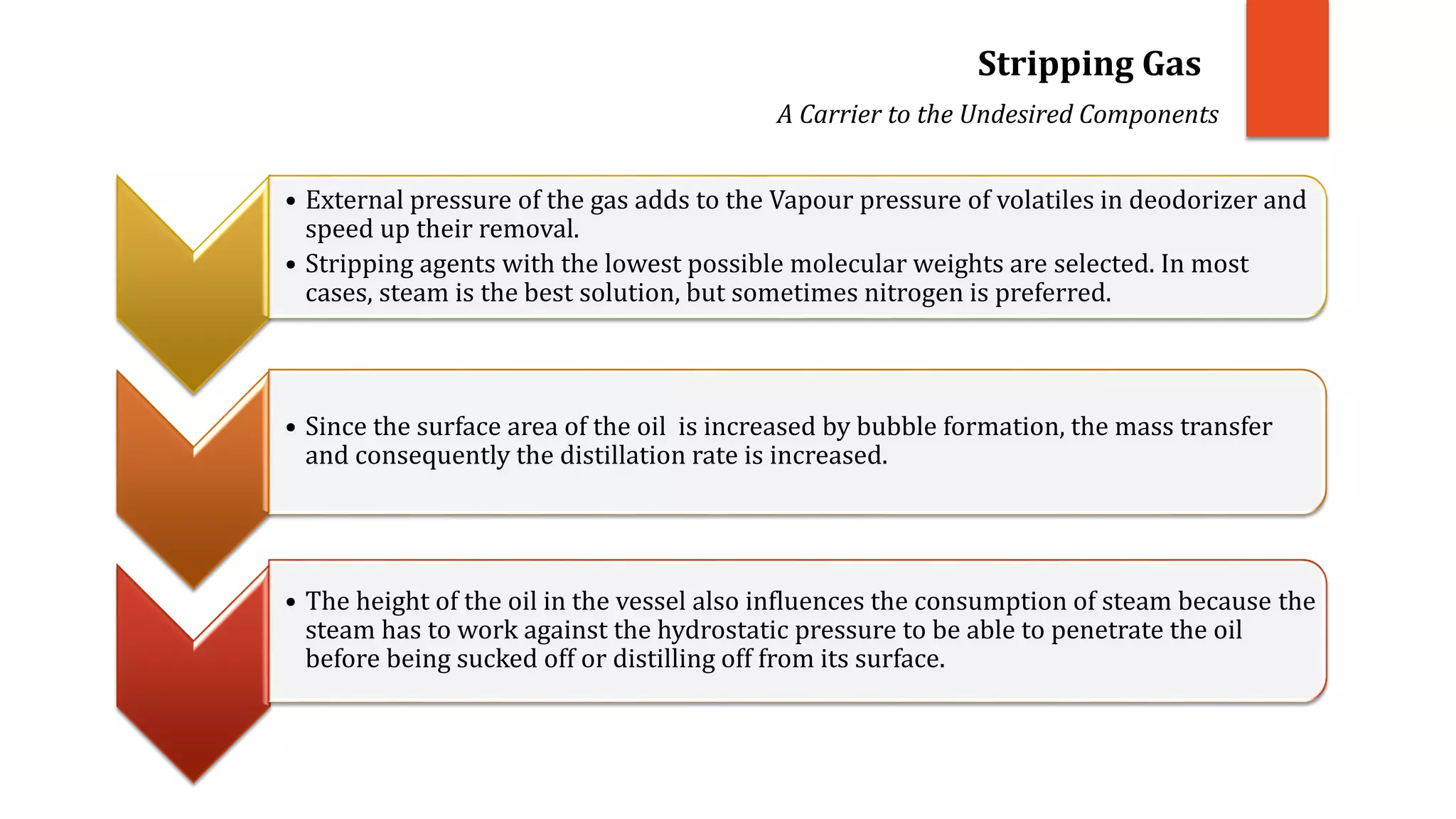

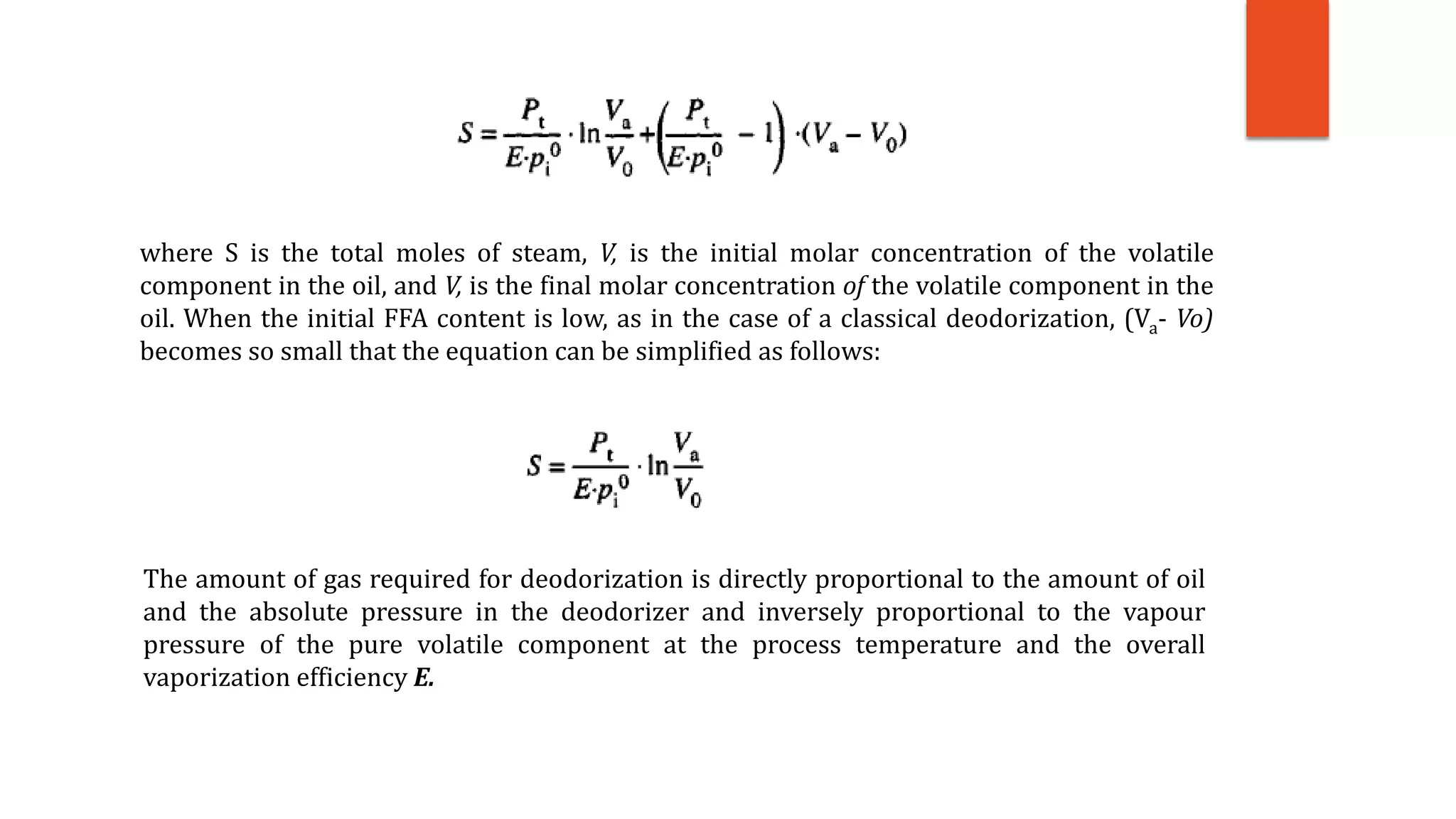

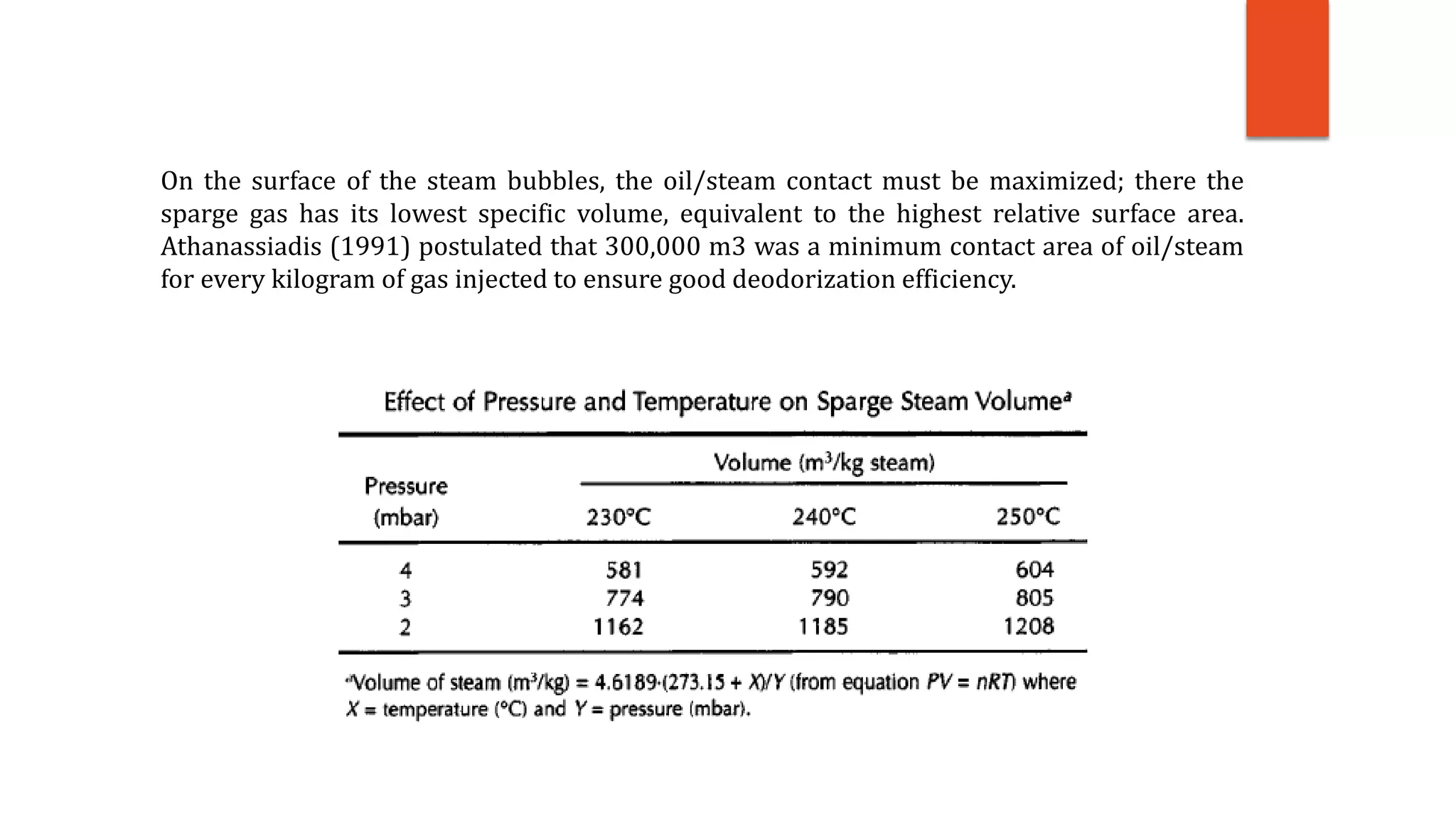

- Deodorization uses high temperature, high vacuum distillation to strip volatile components like free fatty acids and contaminants.

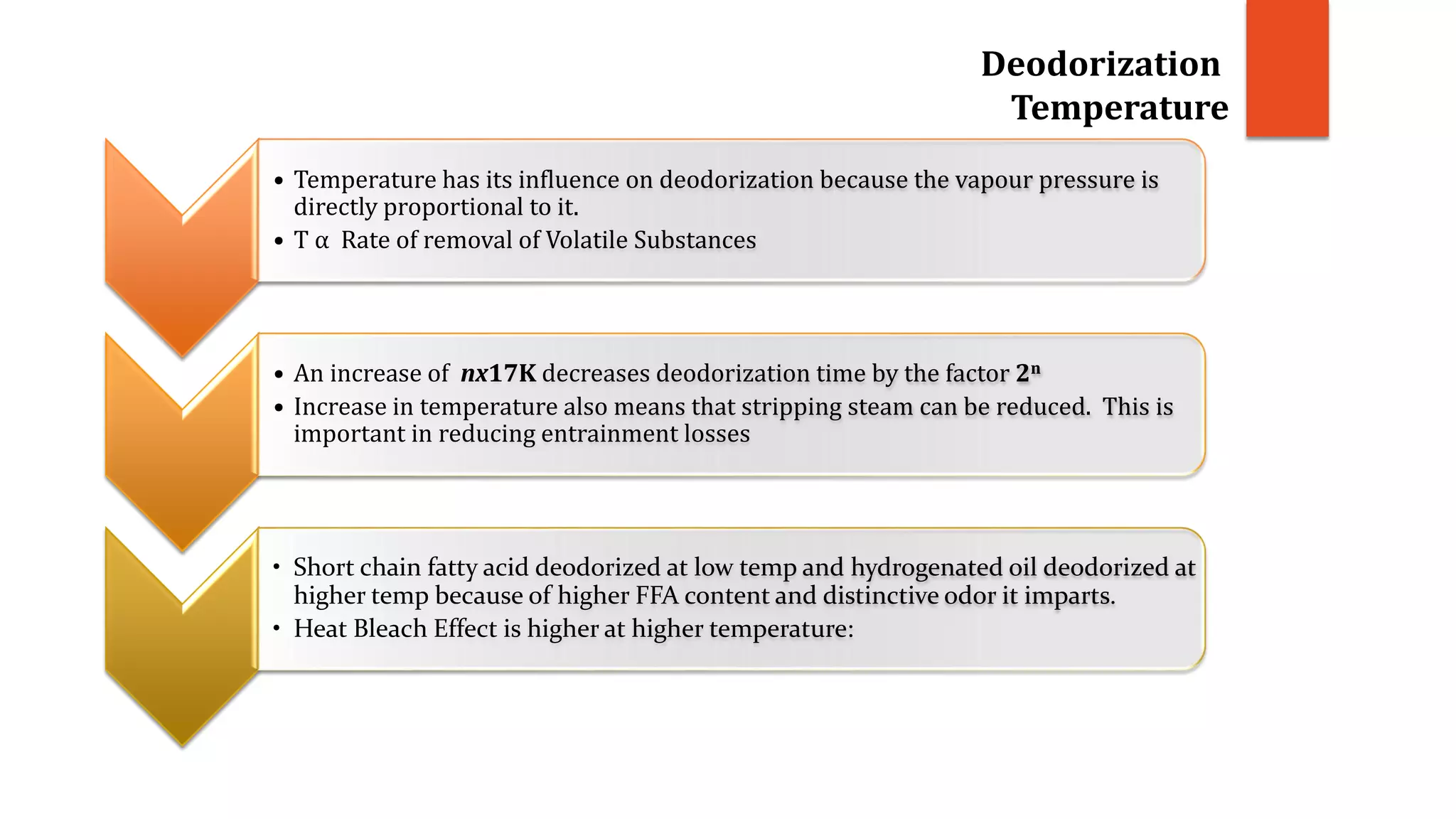

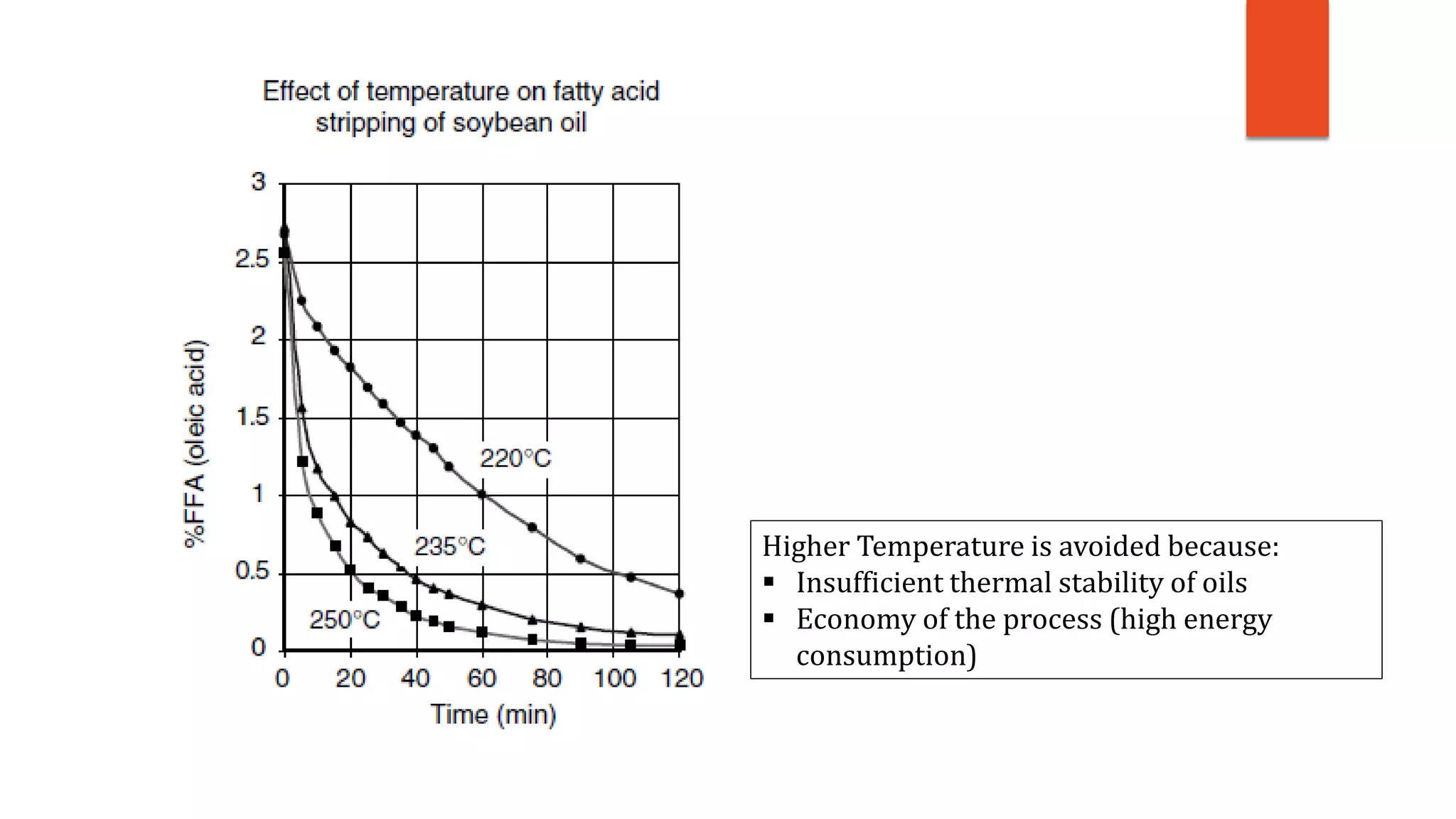

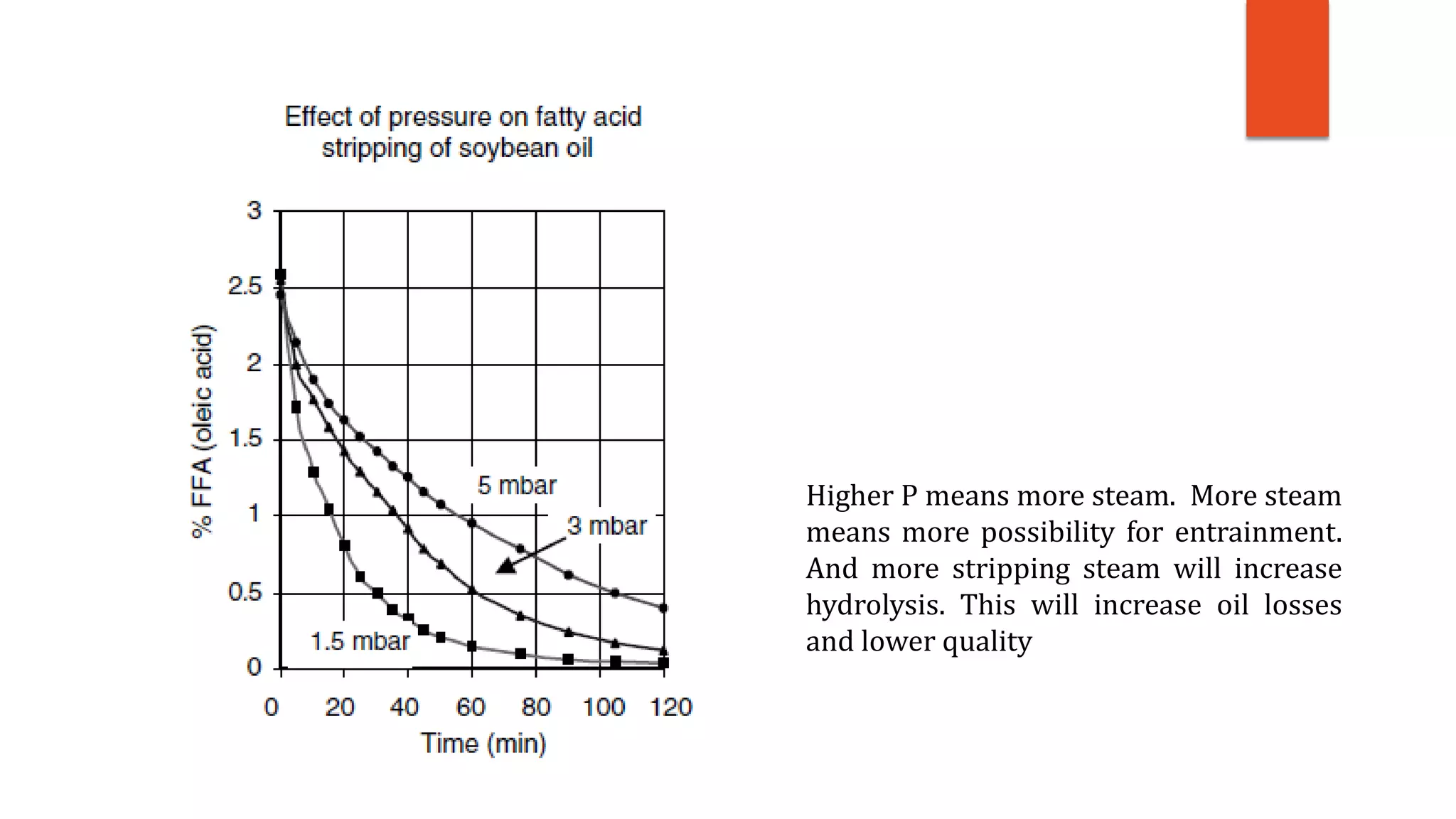

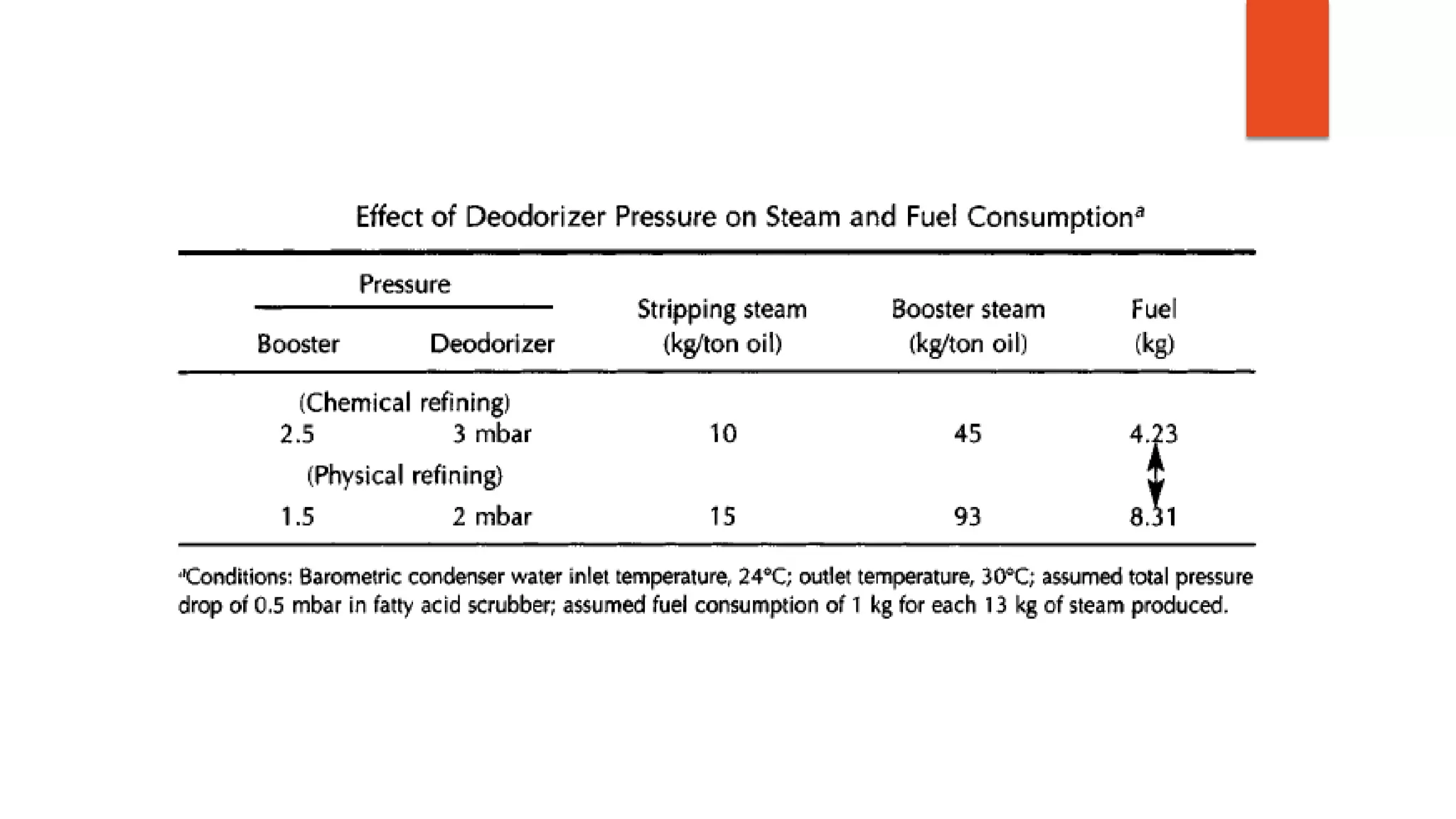

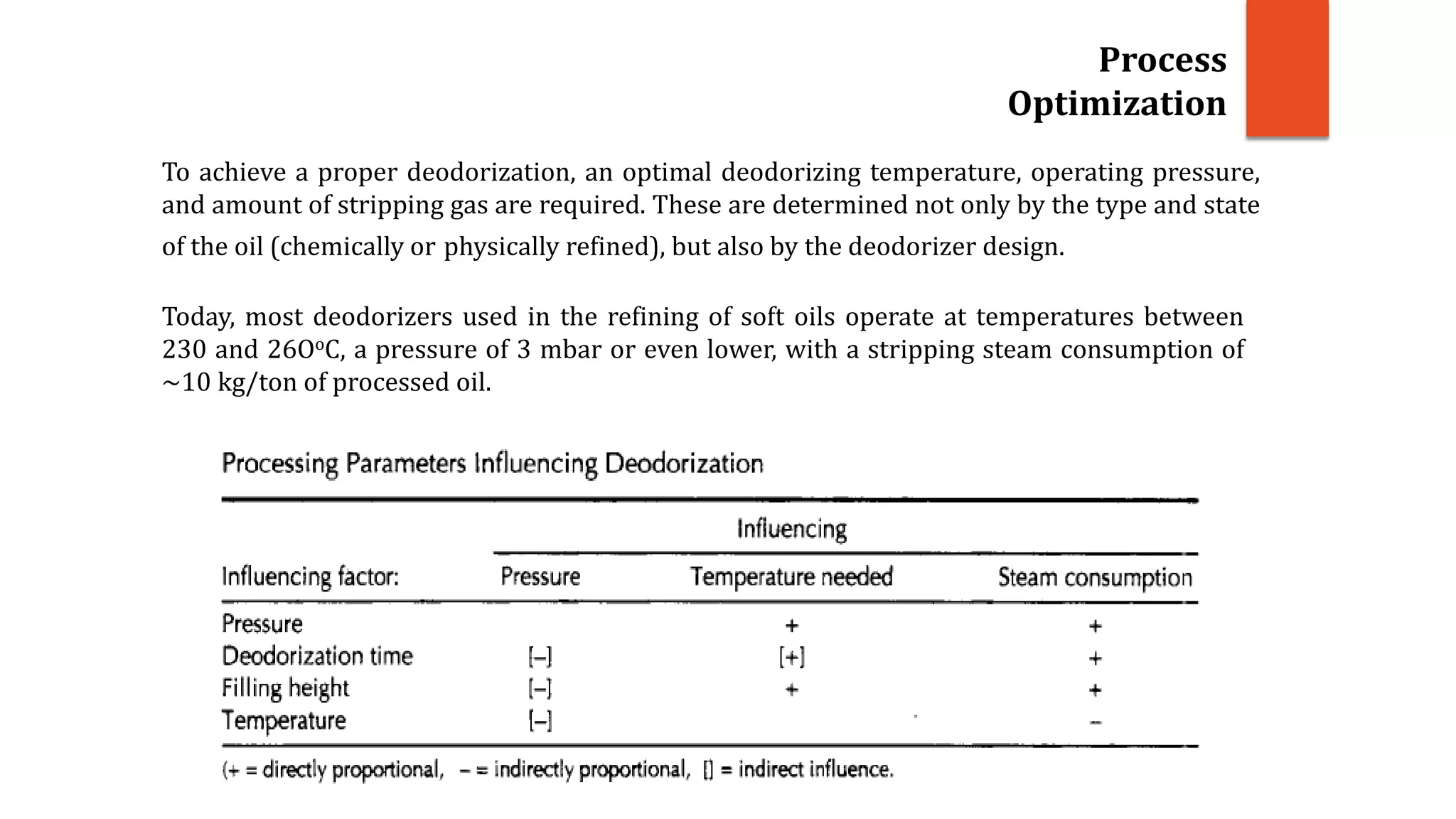

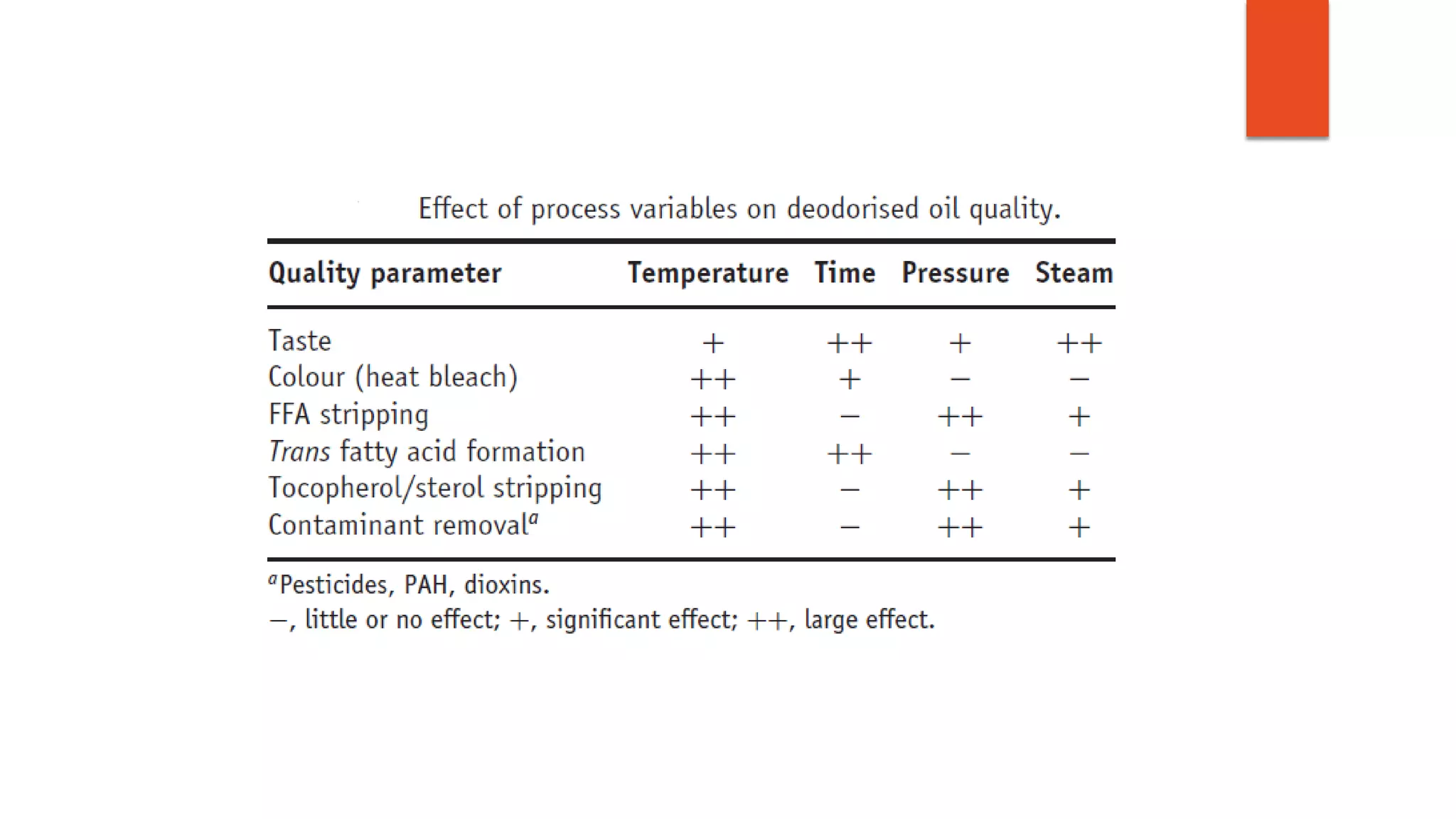

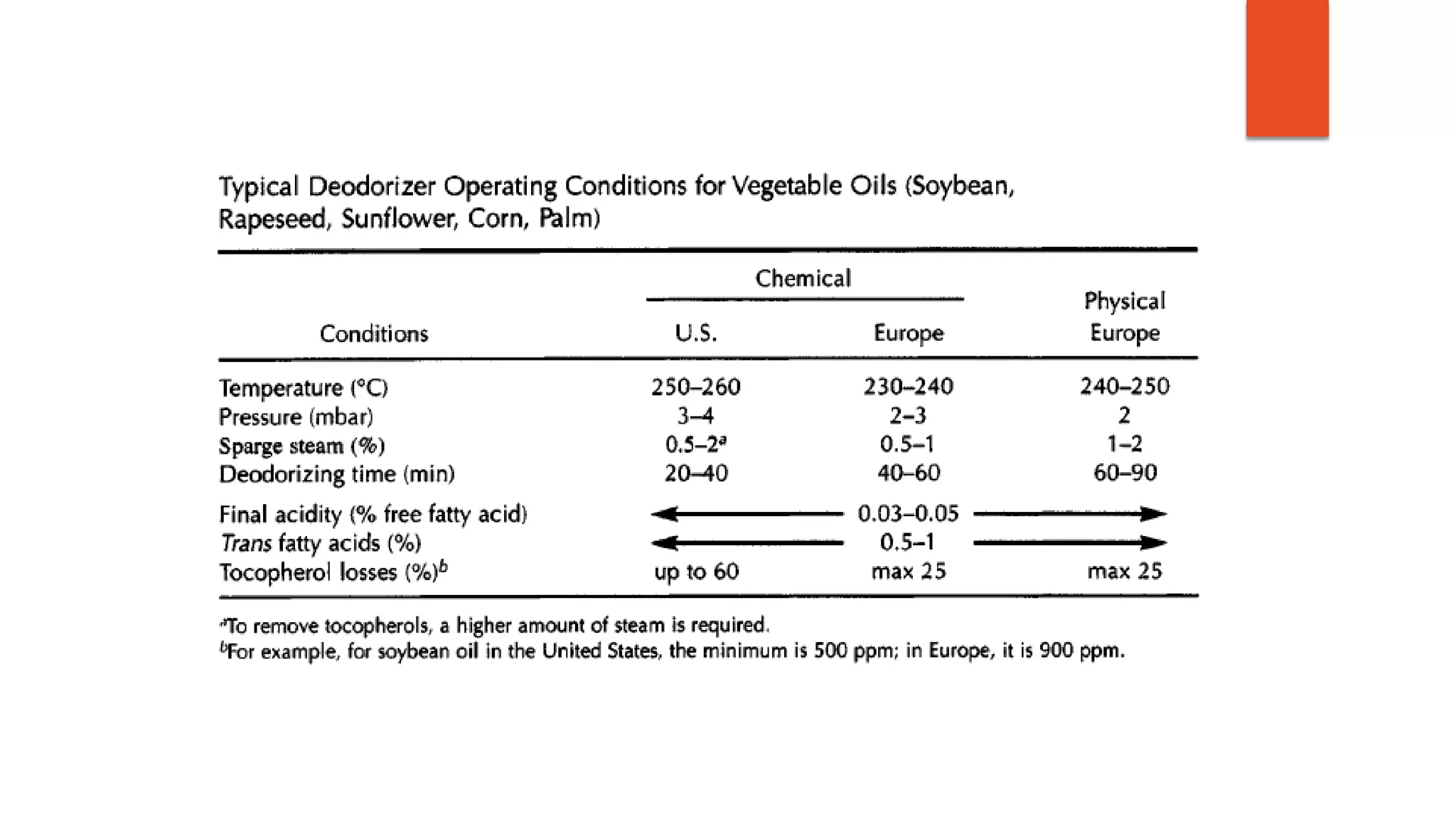

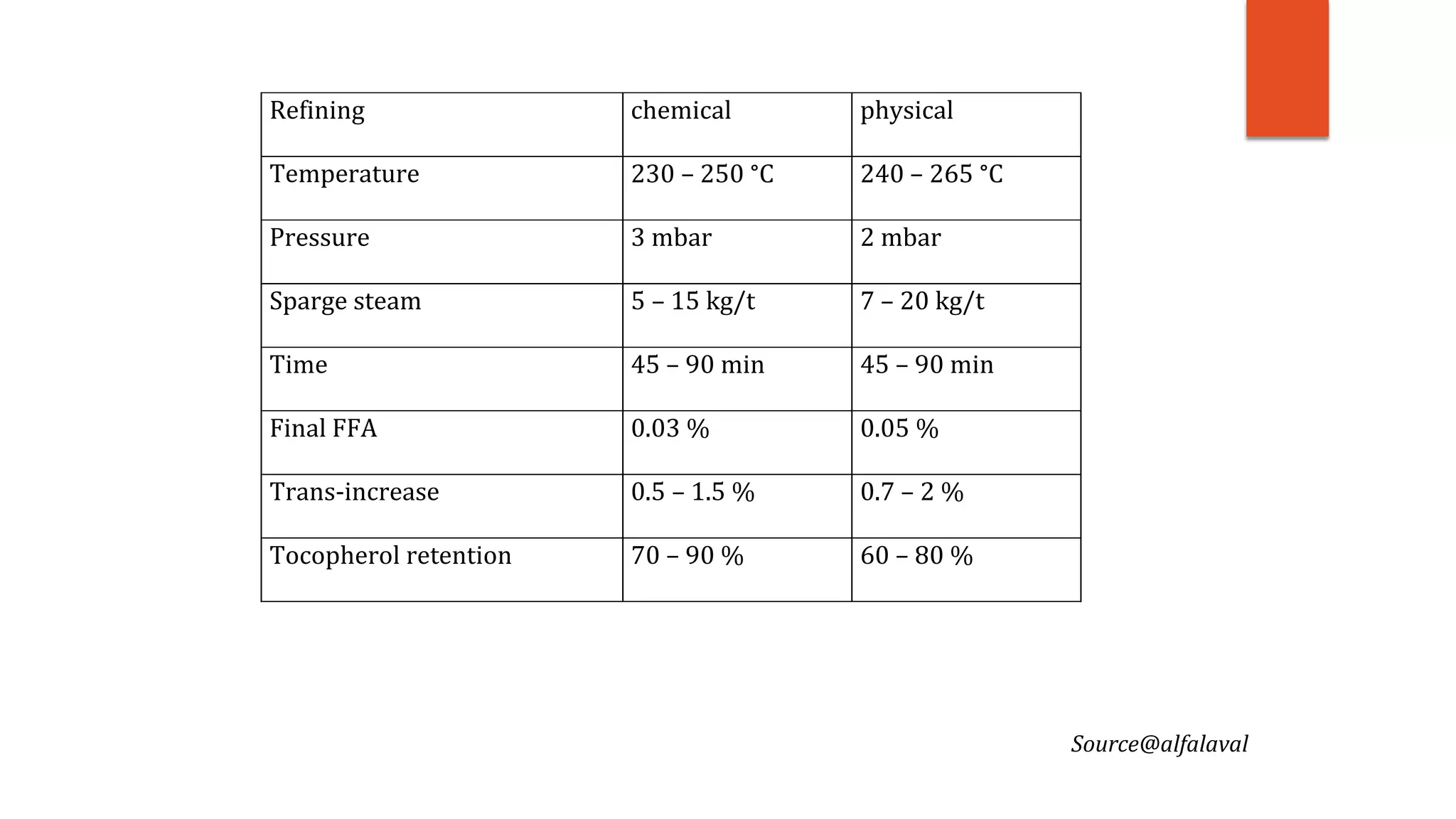

- Process variables like temperature, pressure, time and steam usage influence the removal of odors and quality of the final oil.

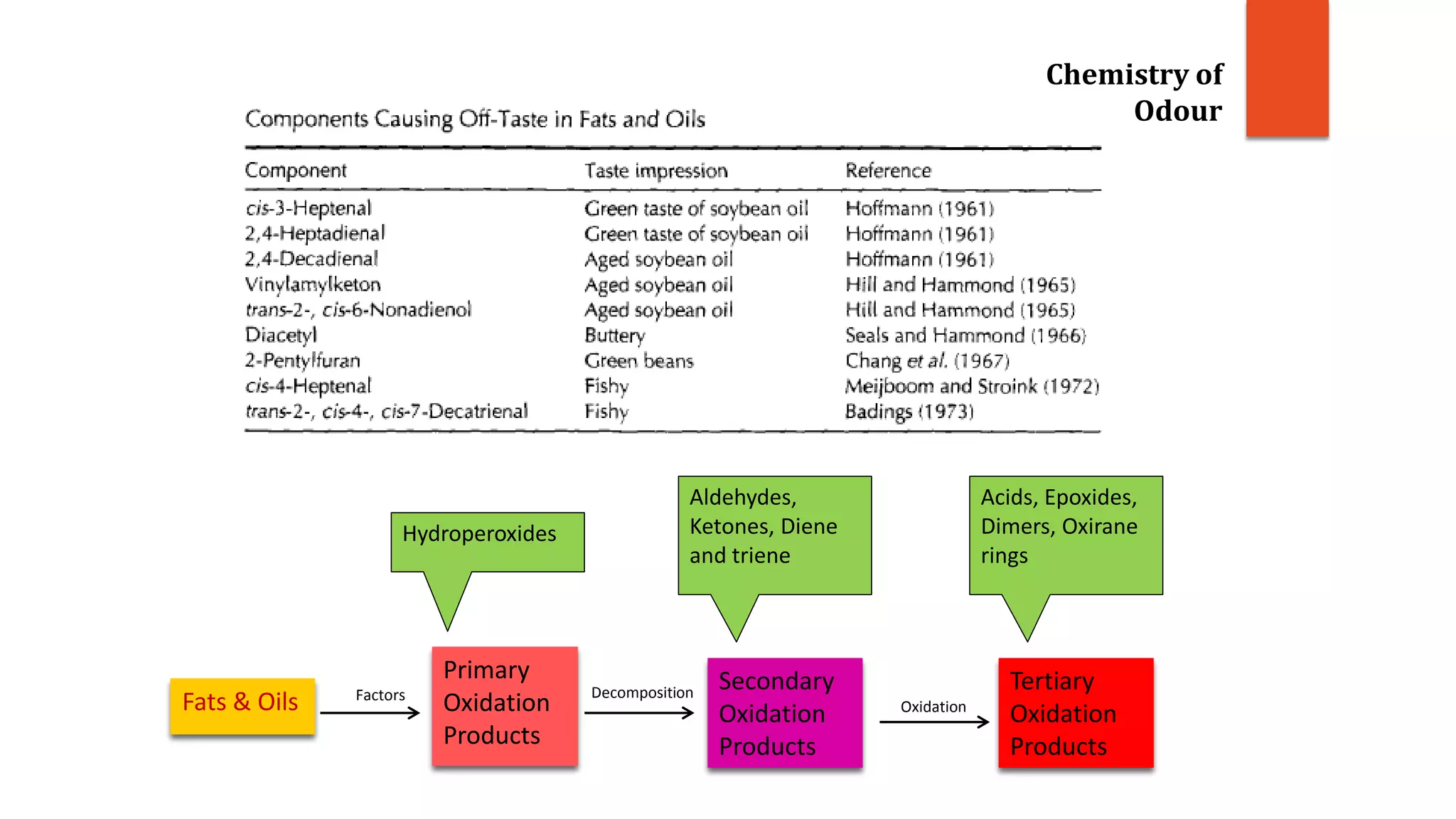

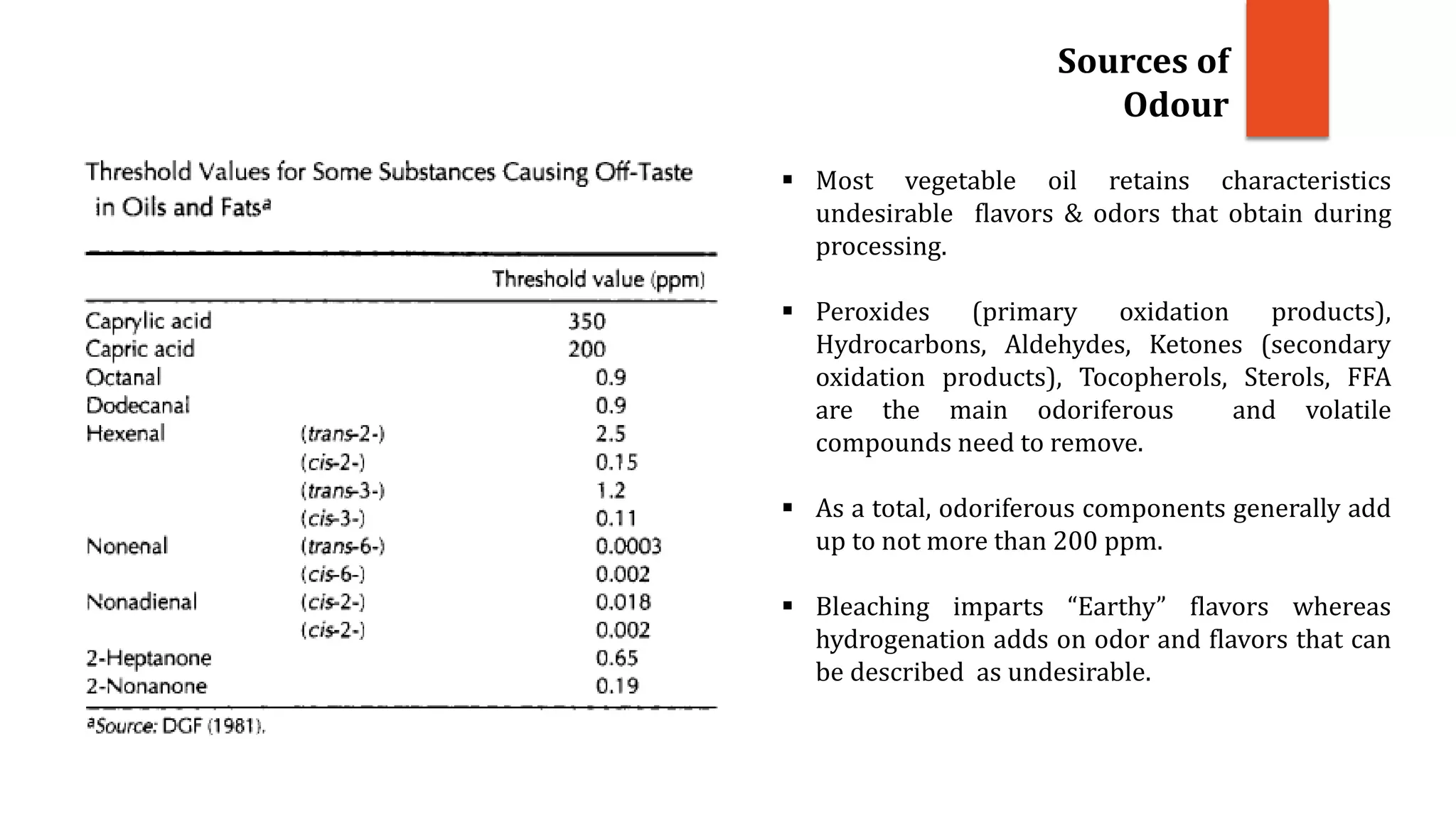

- Common odor sources in oils include oxidation products and thermal degradation compounds.

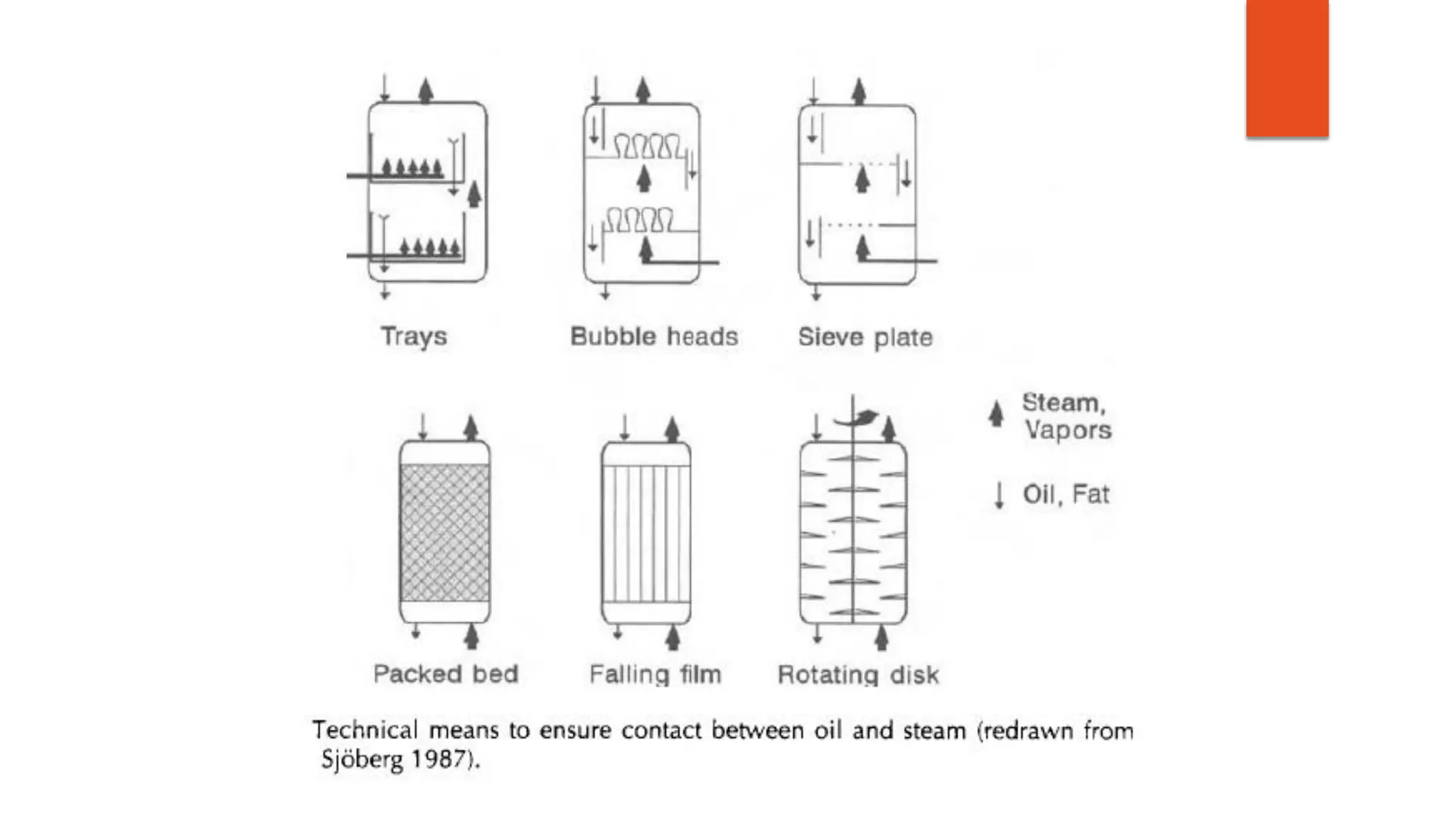

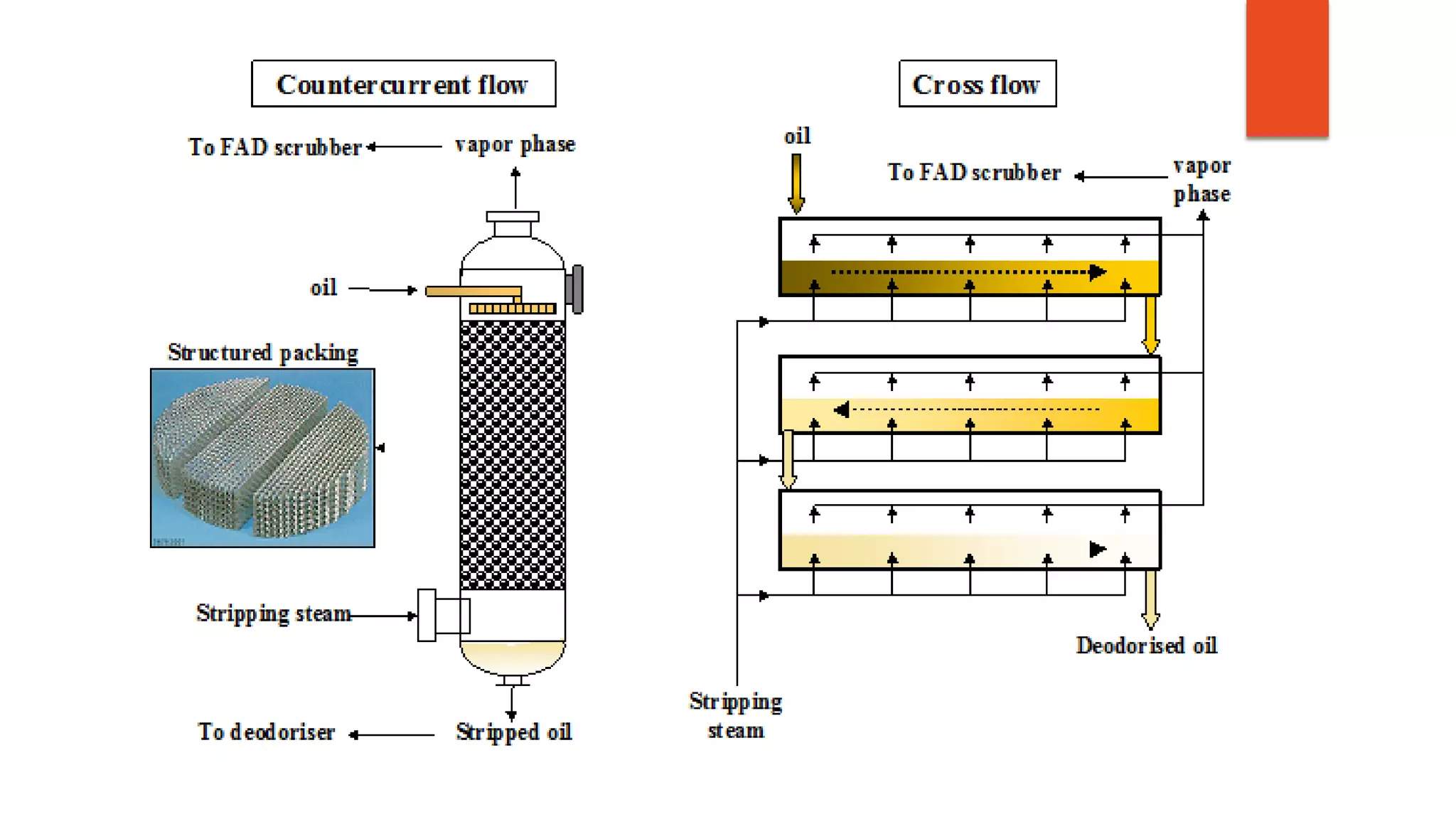

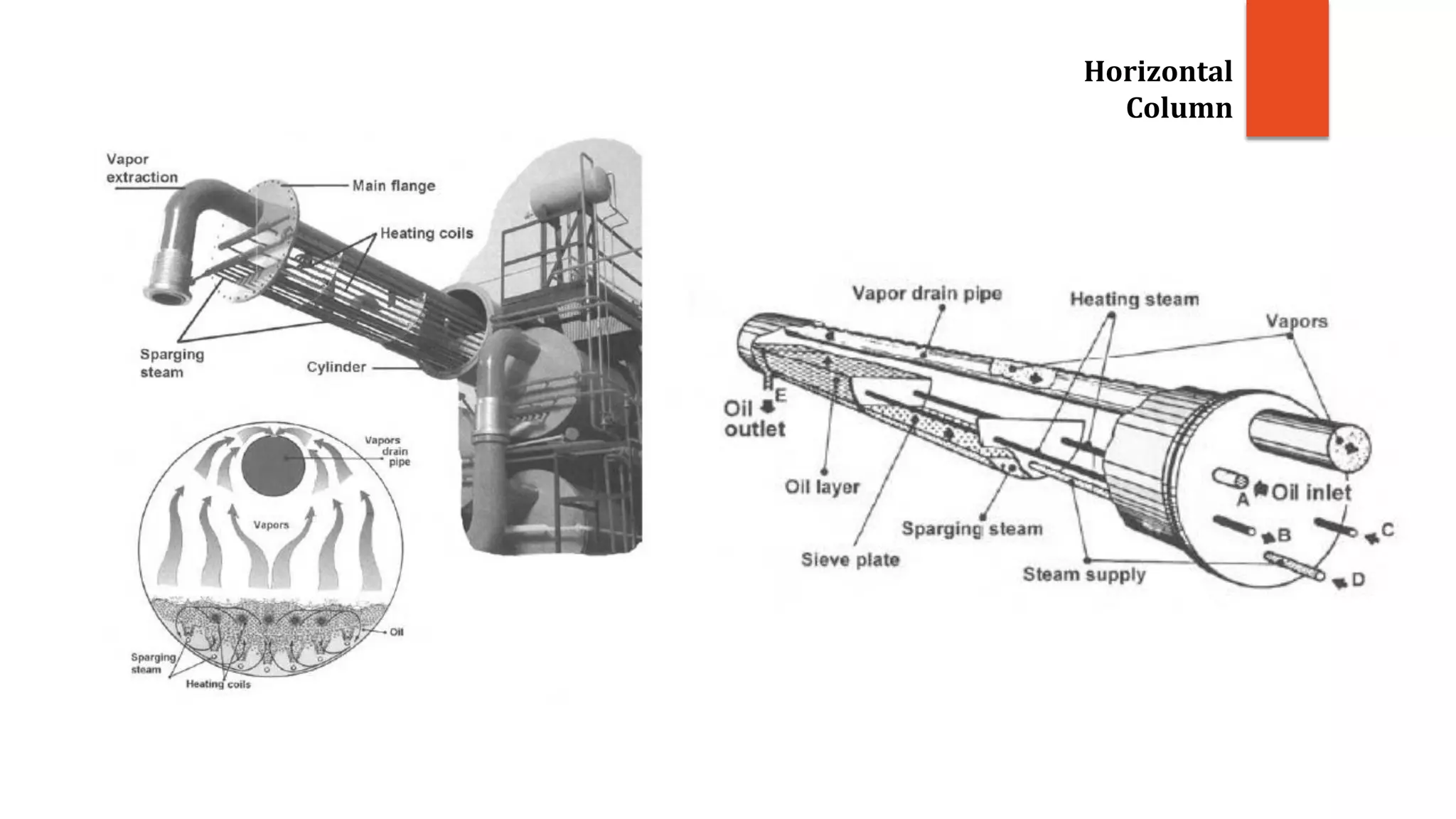

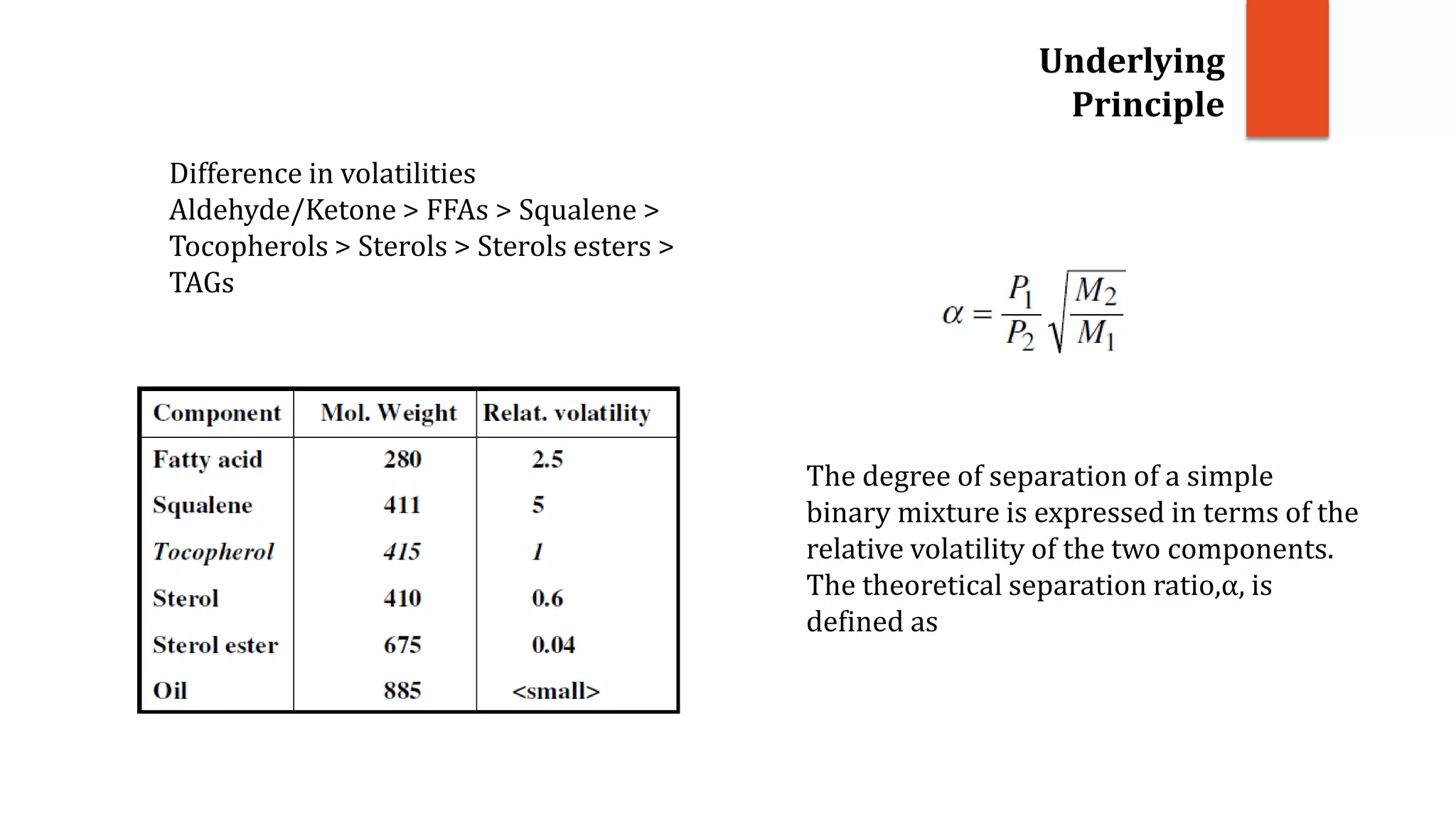

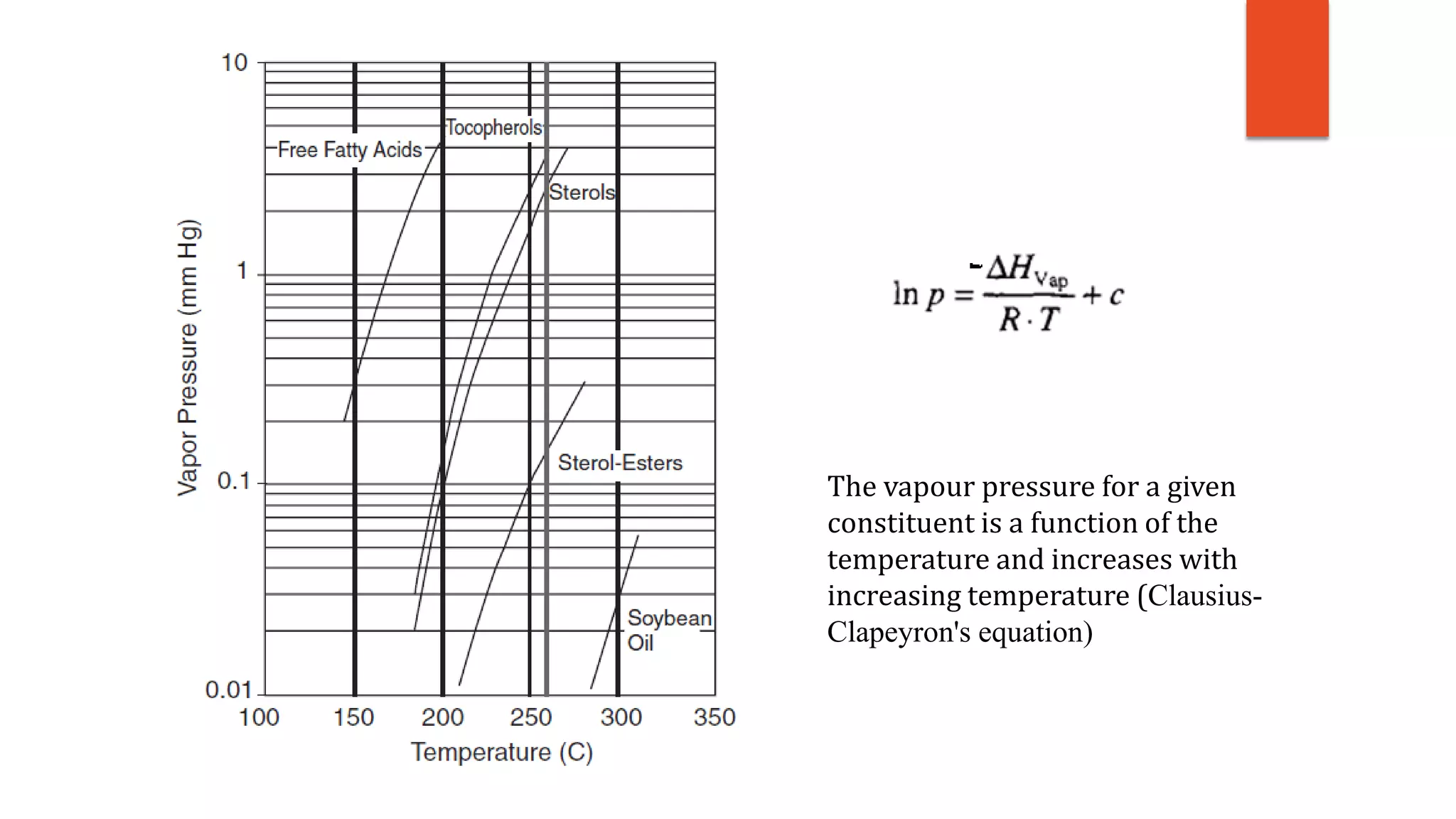

- The underlying principles of deodorization relate to the differing volatilities of oil constituents and steam stripping them away.

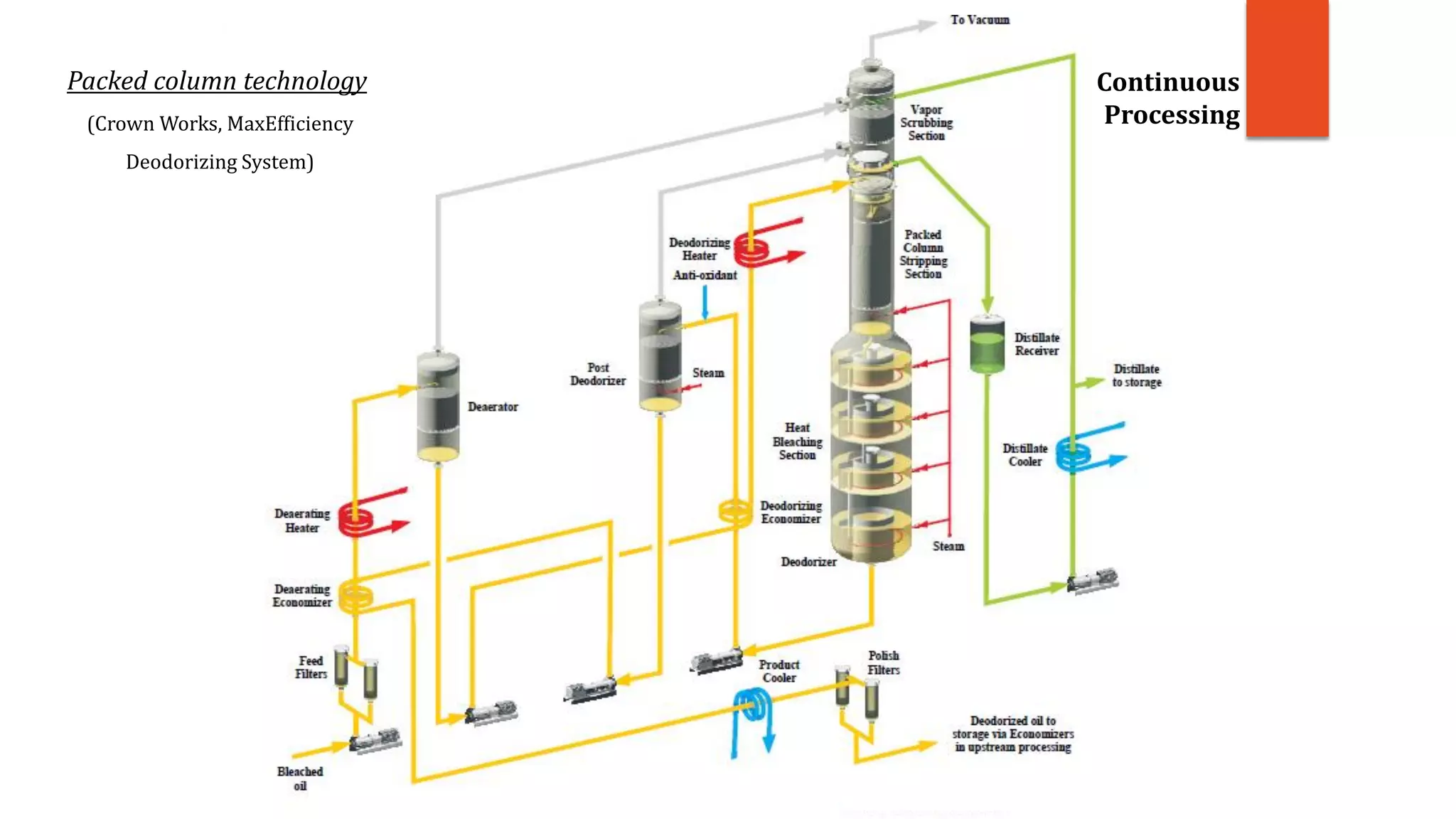

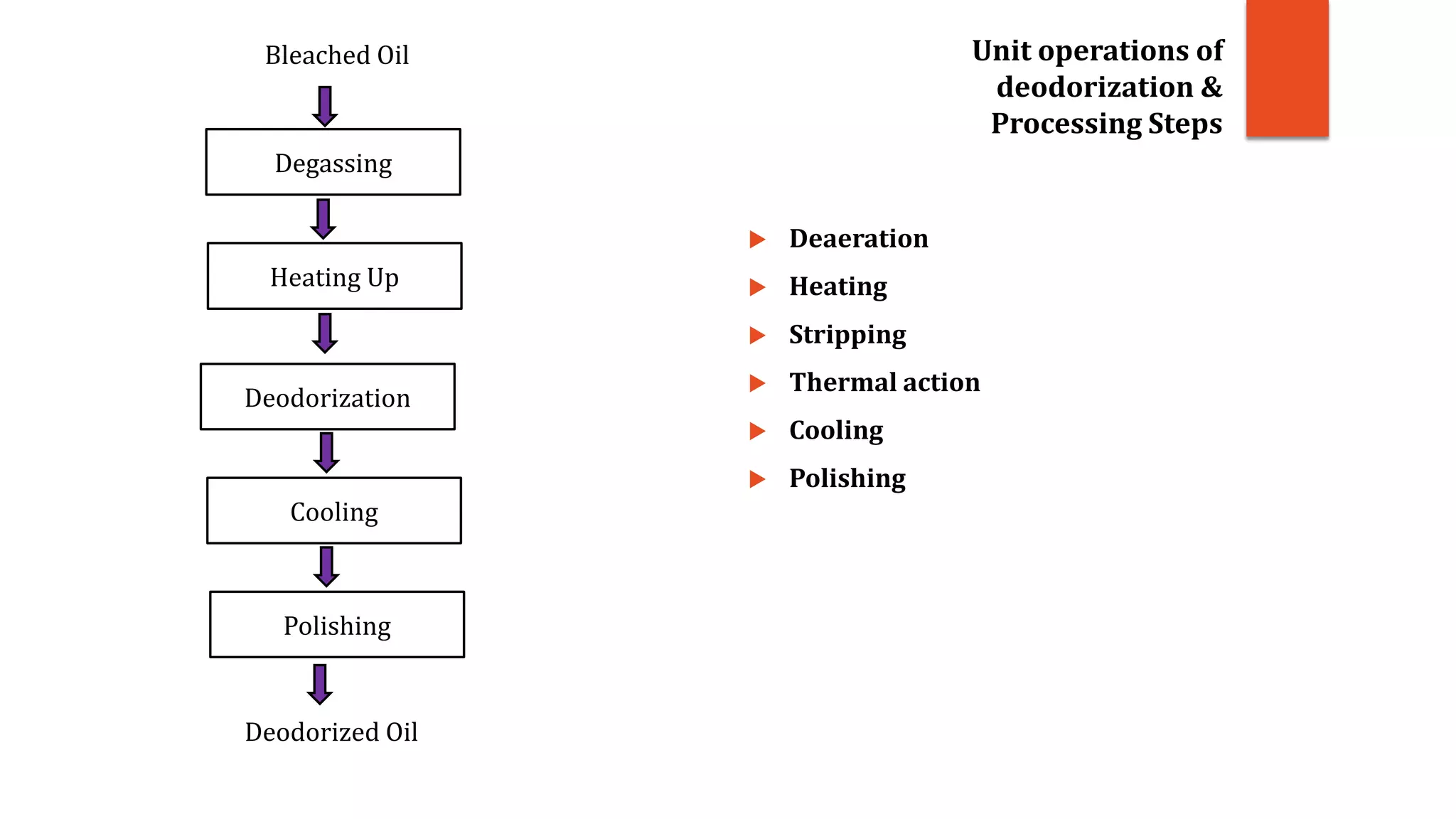

- Typical process steps are

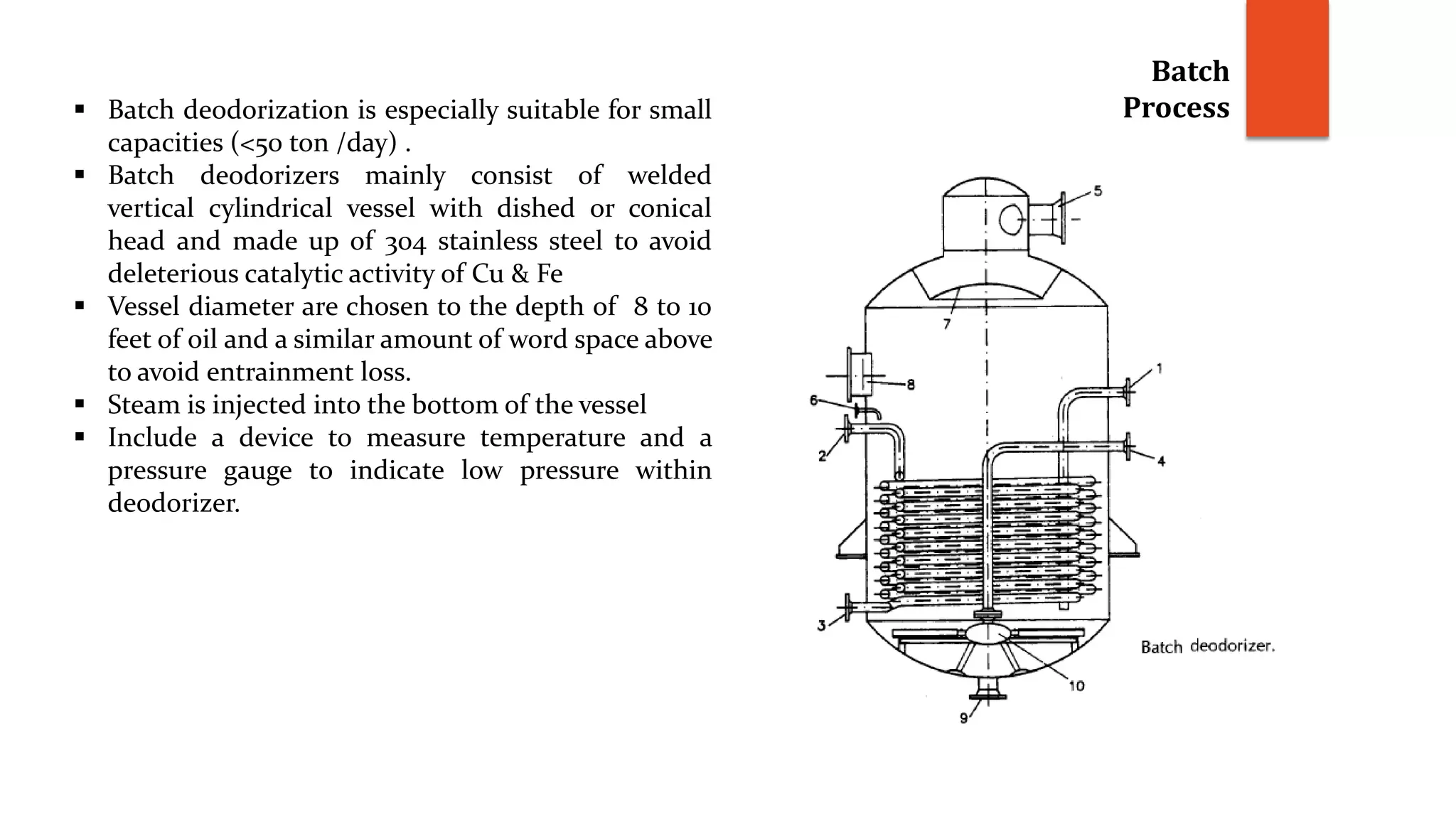

![Heating of the oil is usually accomplished in two stages.

First stage,

Oil is heated counter-currently in an oil-oil heat exchanger (economizer), with the finished

oil leaving the deodorizer.

Second stage,

Oil is heated under reduced pressure to deodorizing temperature with a high temperature

source such as high pressure steam, heat transfer fluids. Saturated steam of -50 bar is

required to heat the oil to 240-260°C.

Heating

(Heating energy required

for a deodorizing system)

where O is the amount of oil (kg), T1 and T2 are the incoming

and final temperature of the oil (°C), C is the average specific

heat capacity of vegetable oils [typically 2.2-2.4 kJ/(kg. °C)], fL is

the heat loss factor from radiation typically 1.05-1.15) and fR, is

the heat recovery factor [ 1 - (%heat recovery/100)].](https://image.slidesharecdn.com/deodorization-unitoperationinoilprocessing-140815155452-phpapp01/75/Deodorization-Important-Unit-operation-in-Oil-Processing-27-2048.jpg)