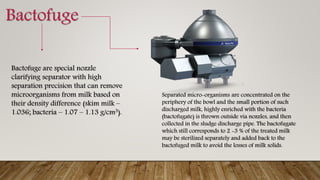

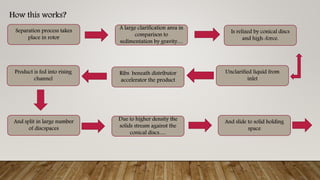

Bactofugation is a process that removes microorganisms like bacteria from milk using centrifugal force. It is commonly used in making hard and semi-hard cheeses. During bactofugation, milk is heated and then centrifuged at high speeds up to 10,000g, which separates bacteria from the milk based on the bacteria's higher density. The concentrated bacteria are removed, reducing bacterial counts by 50-60% without needing excessive heating. This process improves milk quality and purity while allowing the inactivation of heat-resistant spores at lower time-temperature combinations than traditional pasteurization alone.