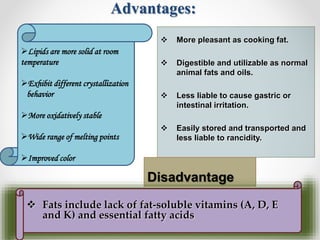

This document discusses animal by-products and their utilization. It notes that 50% of slaughtered animals are converted into by-products rich in protein and fat. These by-products contribute value and are used in foods, pet foods, livestock feeds, and fertilizers. The key process for stabilizing raw materials is rendering, which involves applying heat to evaporate water and sterilize the material. Rendering produces various products like meat, gelatin, edible fats, and pet food ingredients. The document also discusses the properties and uses of different animal fats.