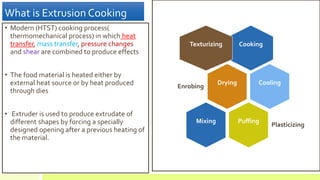

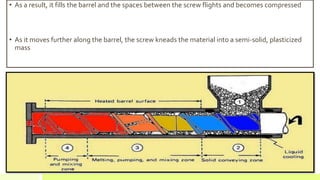

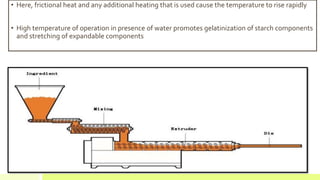

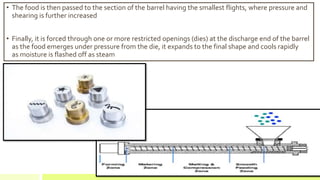

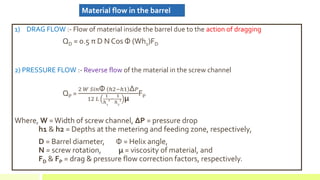

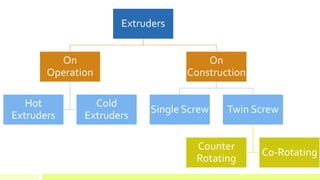

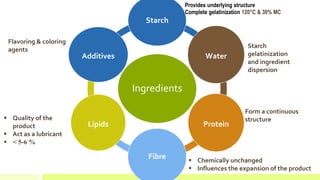

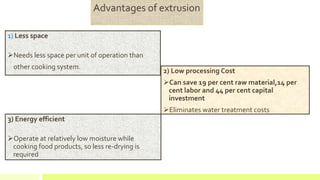

Extrusion processing is a modern cooking technique that uses heat, pressure, shear and friction to produce food products. Raw materials are fed into an extruder barrel containing a screw. As the materials are conveyed down the barrel by the rotating screw, heating and pressure increase viscosity into a semi-solid mass. The plasticized material is then forced through a die to produce the final product shape before cooling. Extrusion cooking offers advantages like lower processing costs, less space requirements, and high production rates. However, it also has disadvantages such as larger minimum lot sizes and higher initial costs.