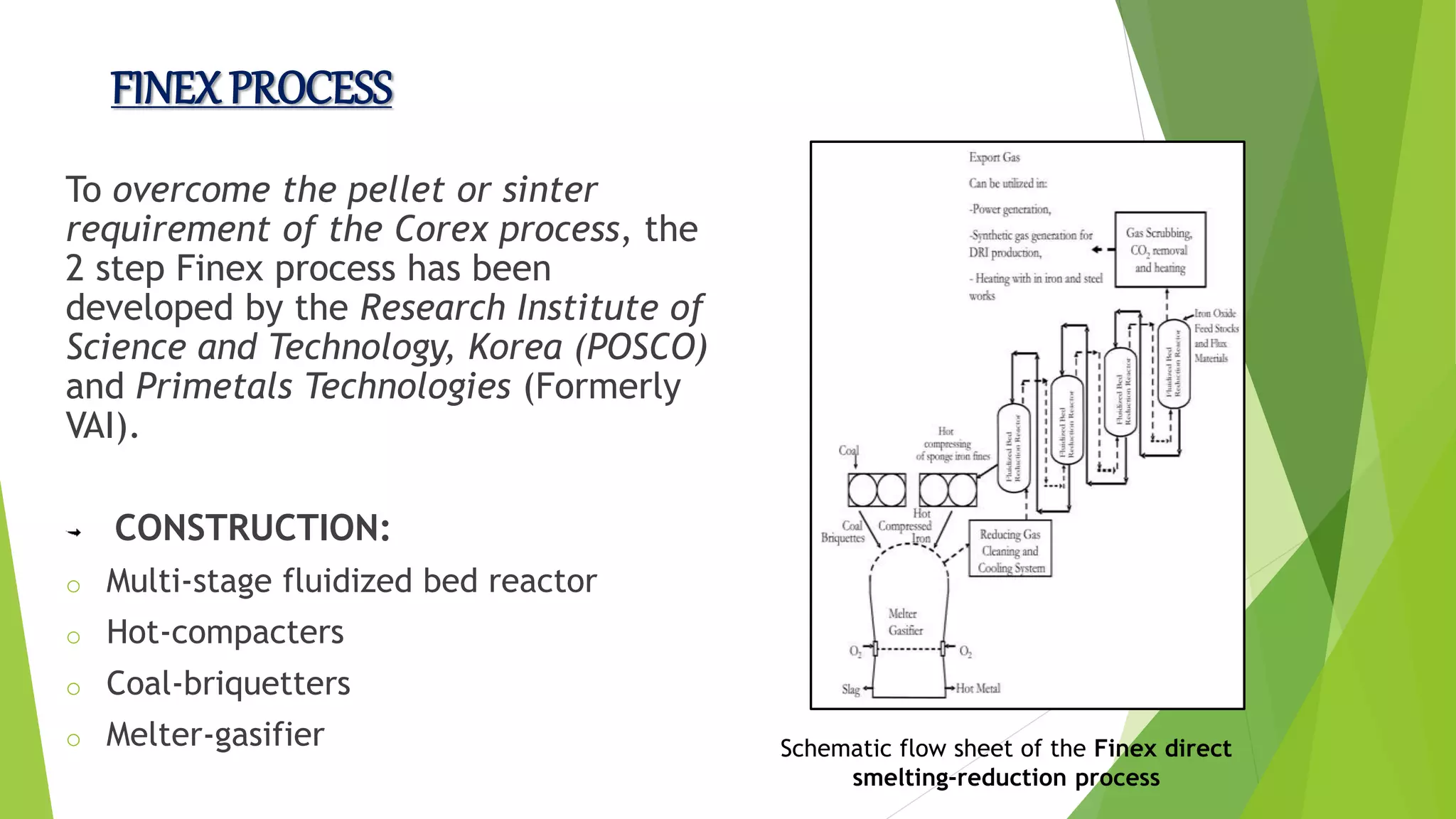

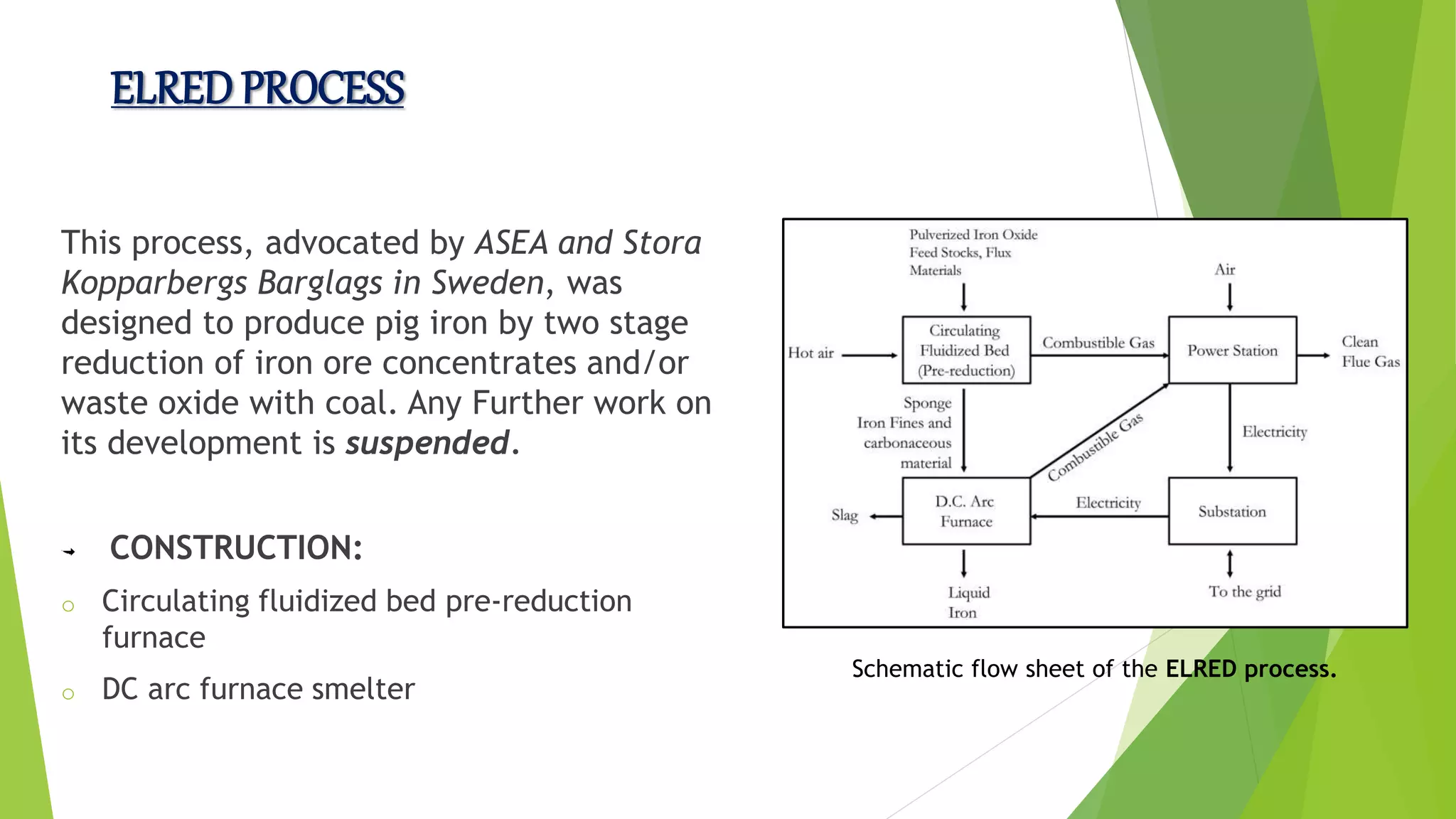

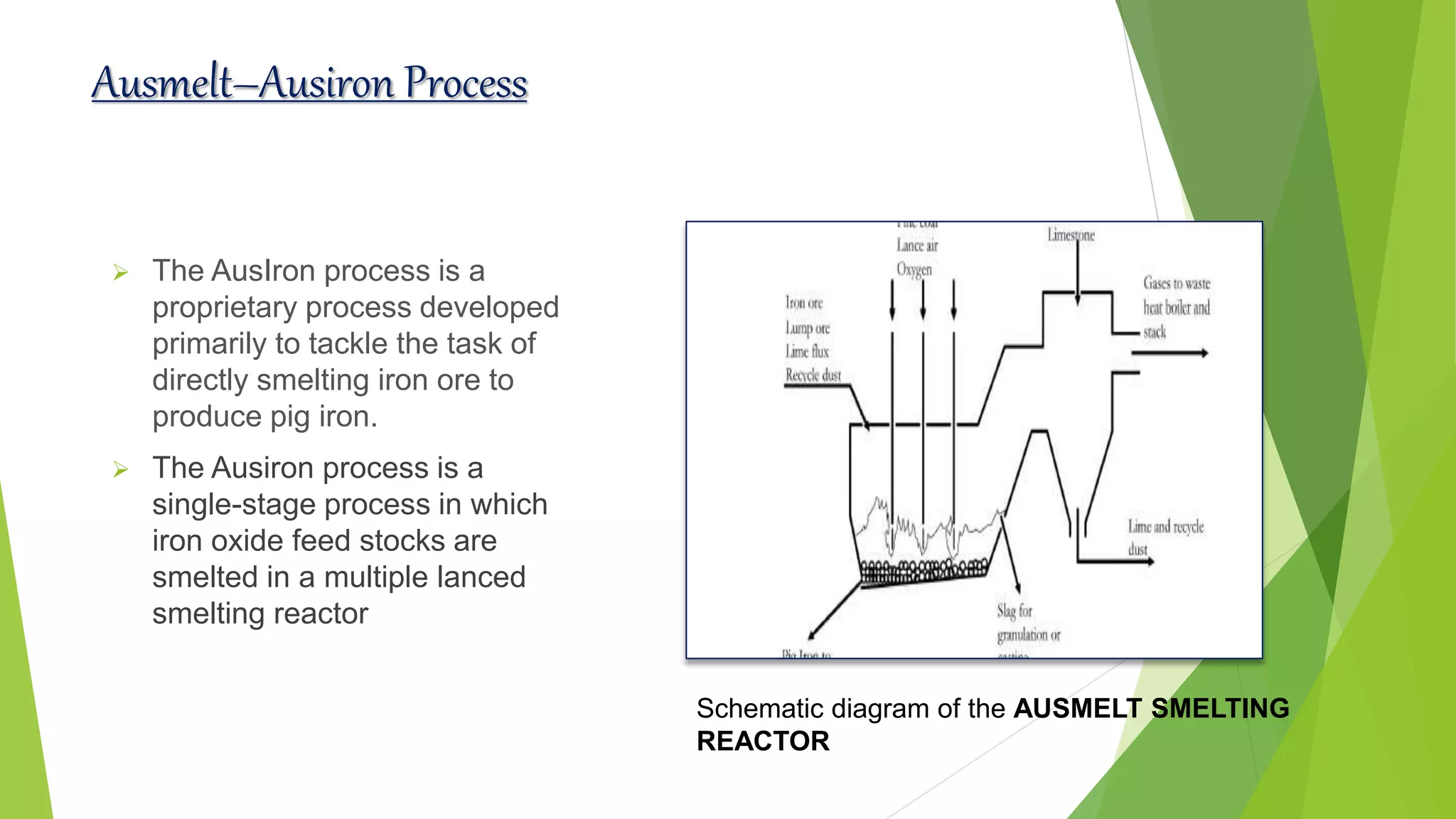

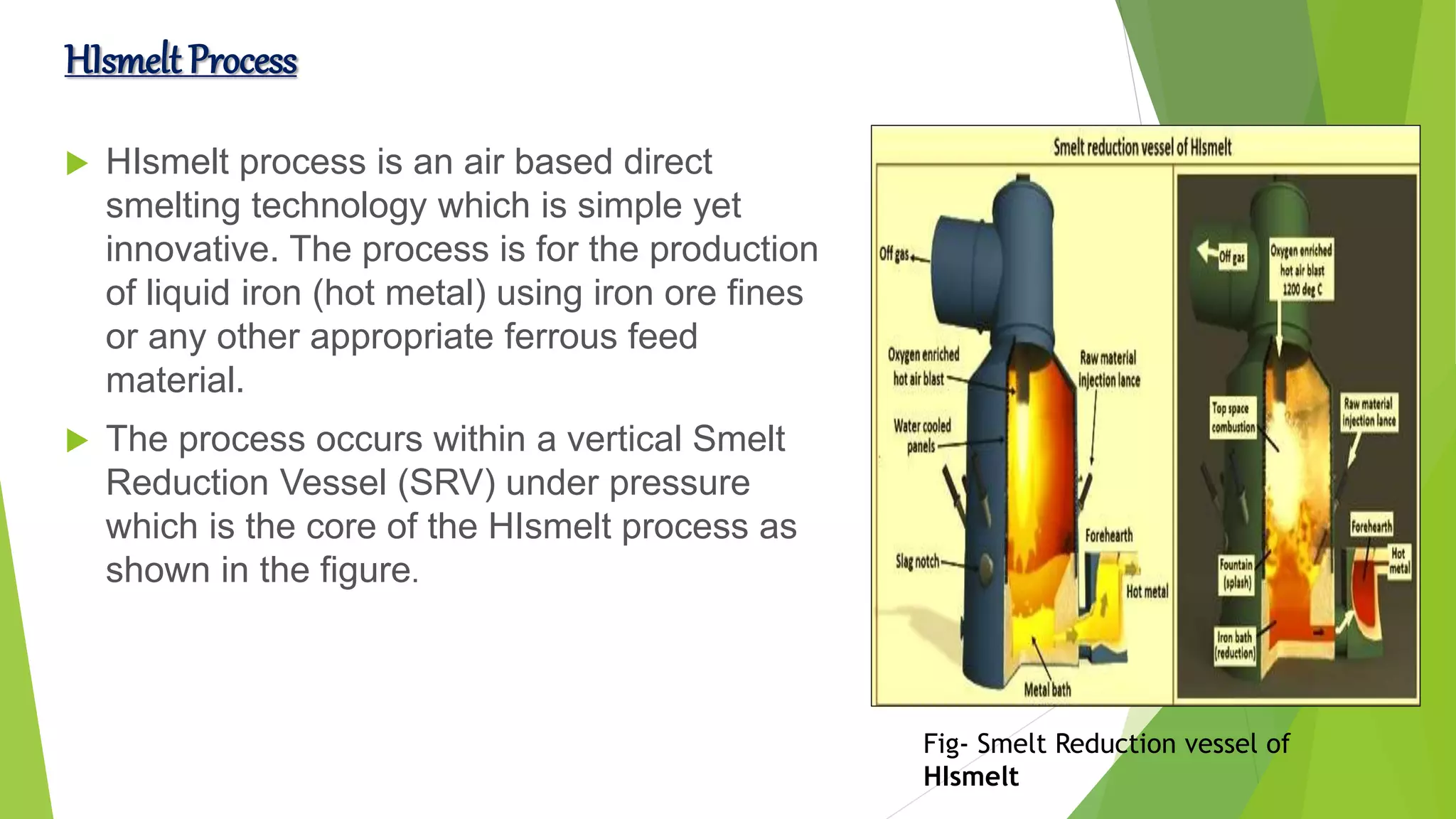

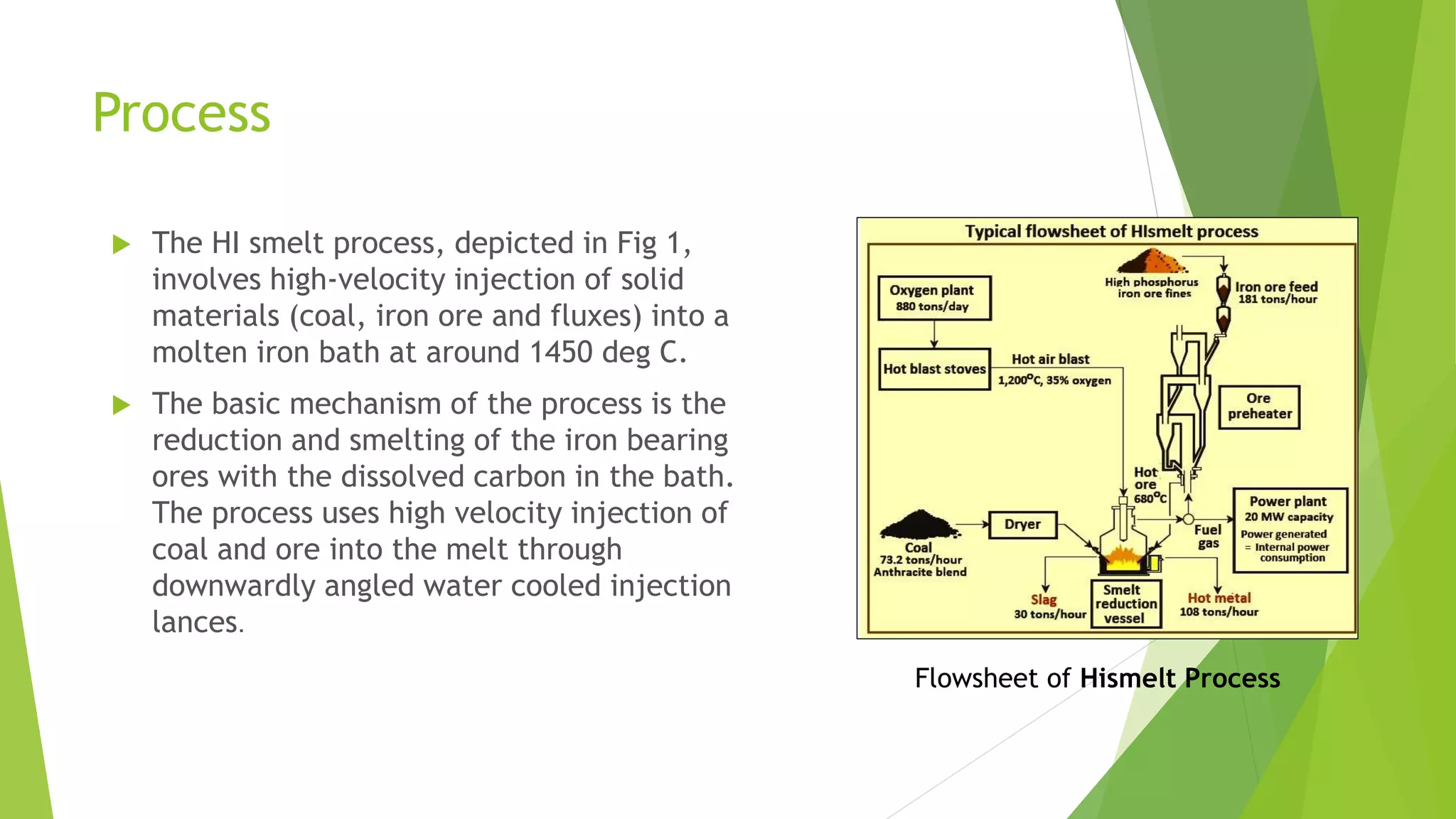

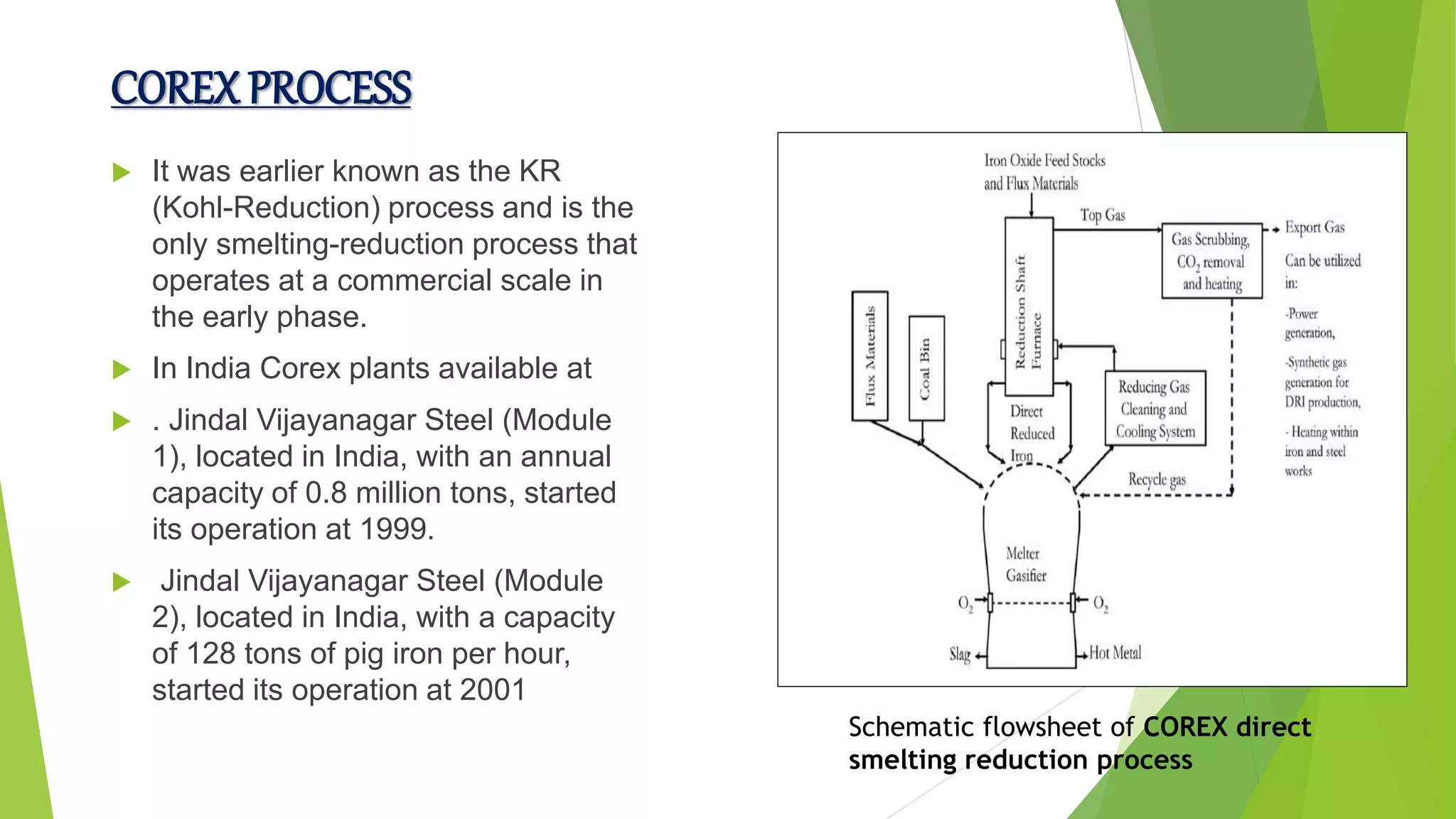

This document summarizes several alternative iron making technologies to the traditional blast furnace process, including direct reduction processes like FINEX and HIsmelt, and smelting reduction processes like Corex and Ausmelt. It describes the basic processes and reactions, advantages like flexibility and lower emissions, and disadvantages such as higher costs. Key alternative processes discussed are FINEX, INRED, ELRED, Ausmelt, HIsmelt, and Corex, with summaries of their process designs and operating principles.