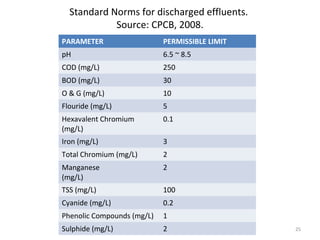

This document summarizes a summer internship project on pollution from coal-based DRI plants. It provides background on DRI production, noting it is a method to produce solid iron from iron oxide without coking coal. DRI production in India has increased significantly in recent years. The document outlines the DRI process and inputs/outputs, identifying particulate matter, SO2, NOx, and CO as main pollutants. It discusses regulatory air pollution standards and water usage at DRI plants. In summary, it analyzes pollution sources from coal-based DRI production and the impact on the surrounding environment.