The document discusses the Hismelt process as an alternative to the blast furnace process for ironmaking. Some key points:

- Hismelt can utilize poorer quality raw materials like non-coking coal and non-agglomerated iron ore fines compared to blast furnaces.

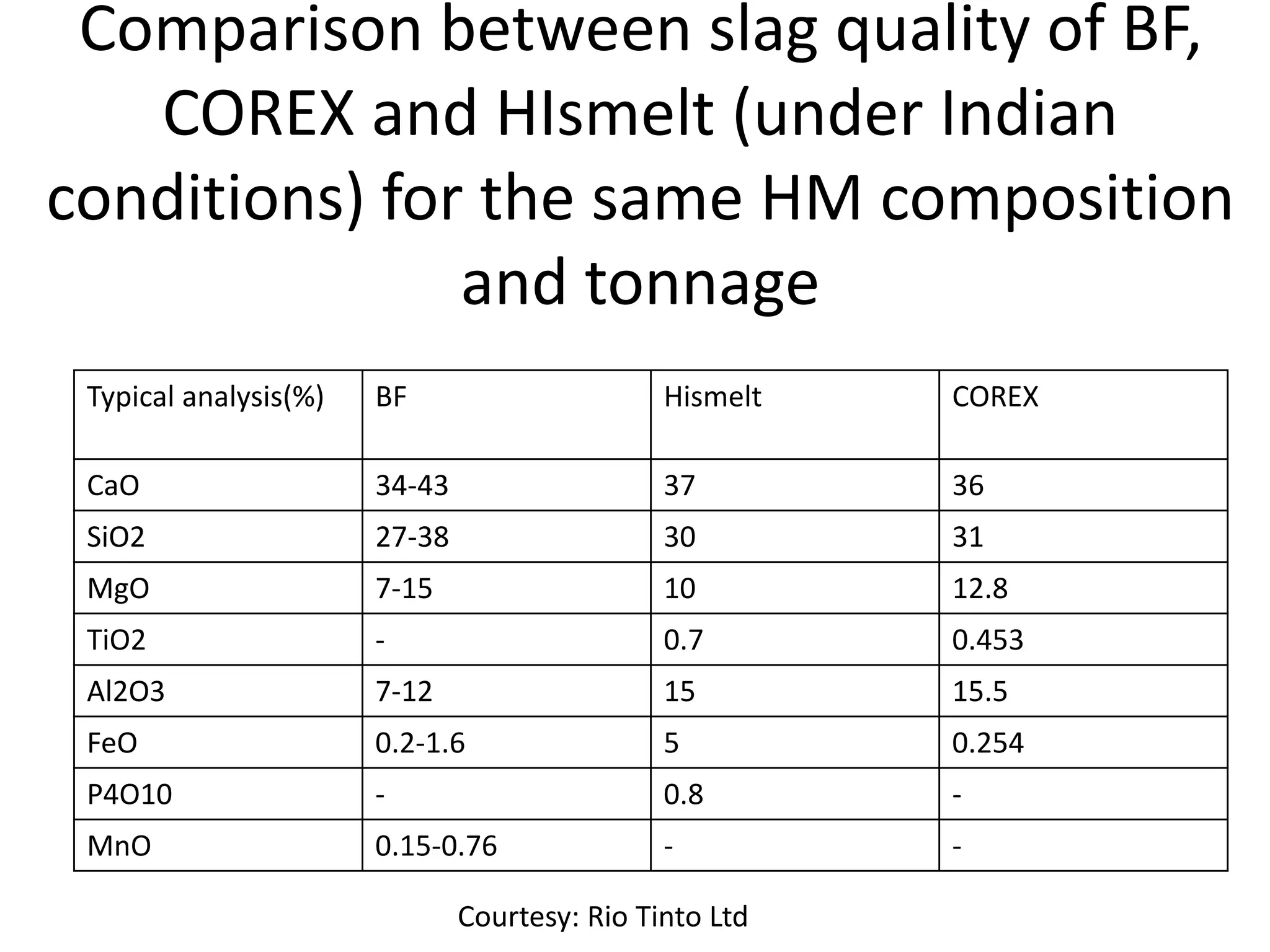

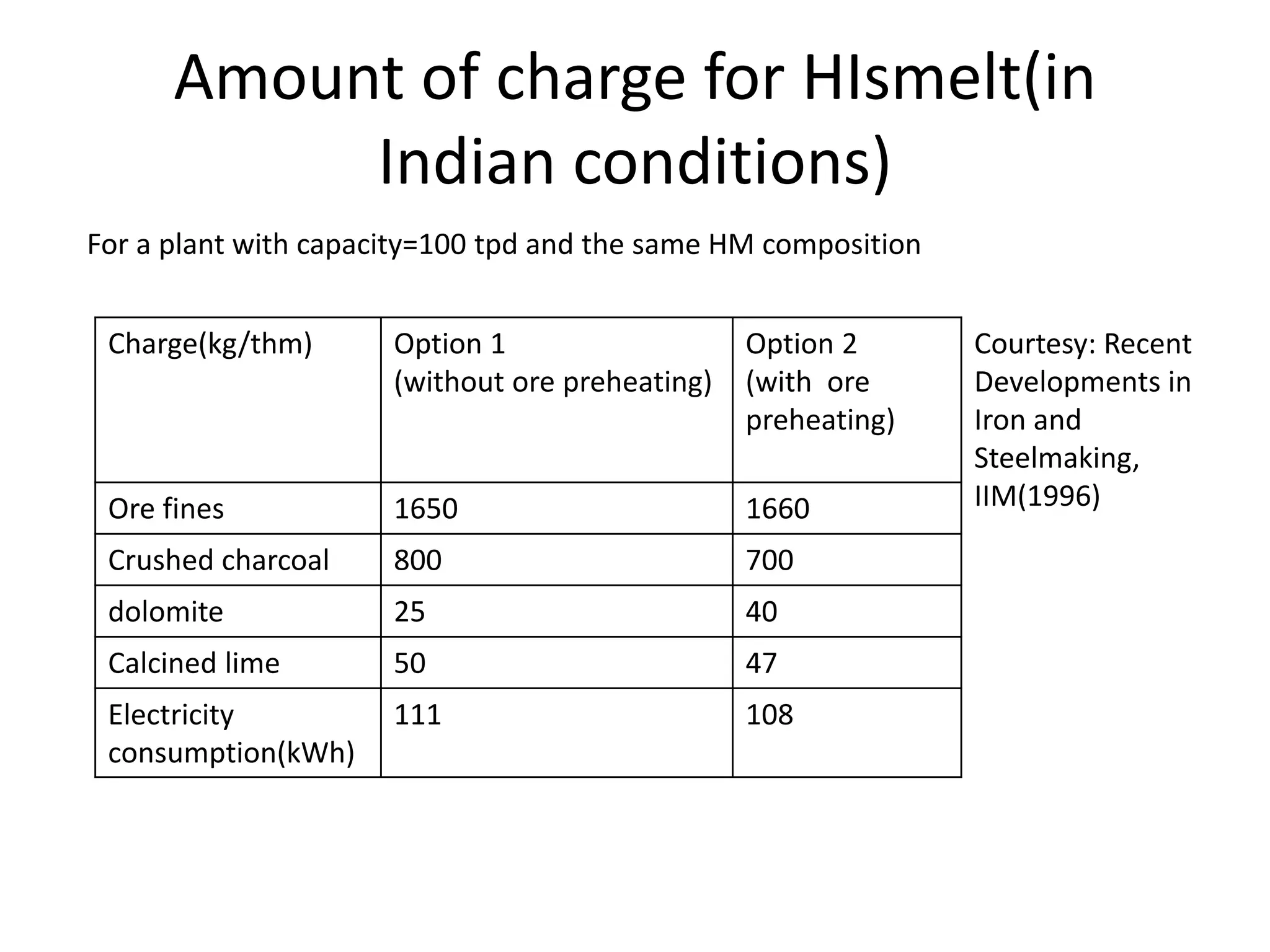

- The process involves injecting iron ore, coal, and fluxes directly into a molten bath where the carbon in the coal reacts with oxygen to reduce the iron ore.

- This allows for higher absorption efficiency and enables use of ultra-fine materials. It also creates conditions for phosphorus to partition strongly to the slag.

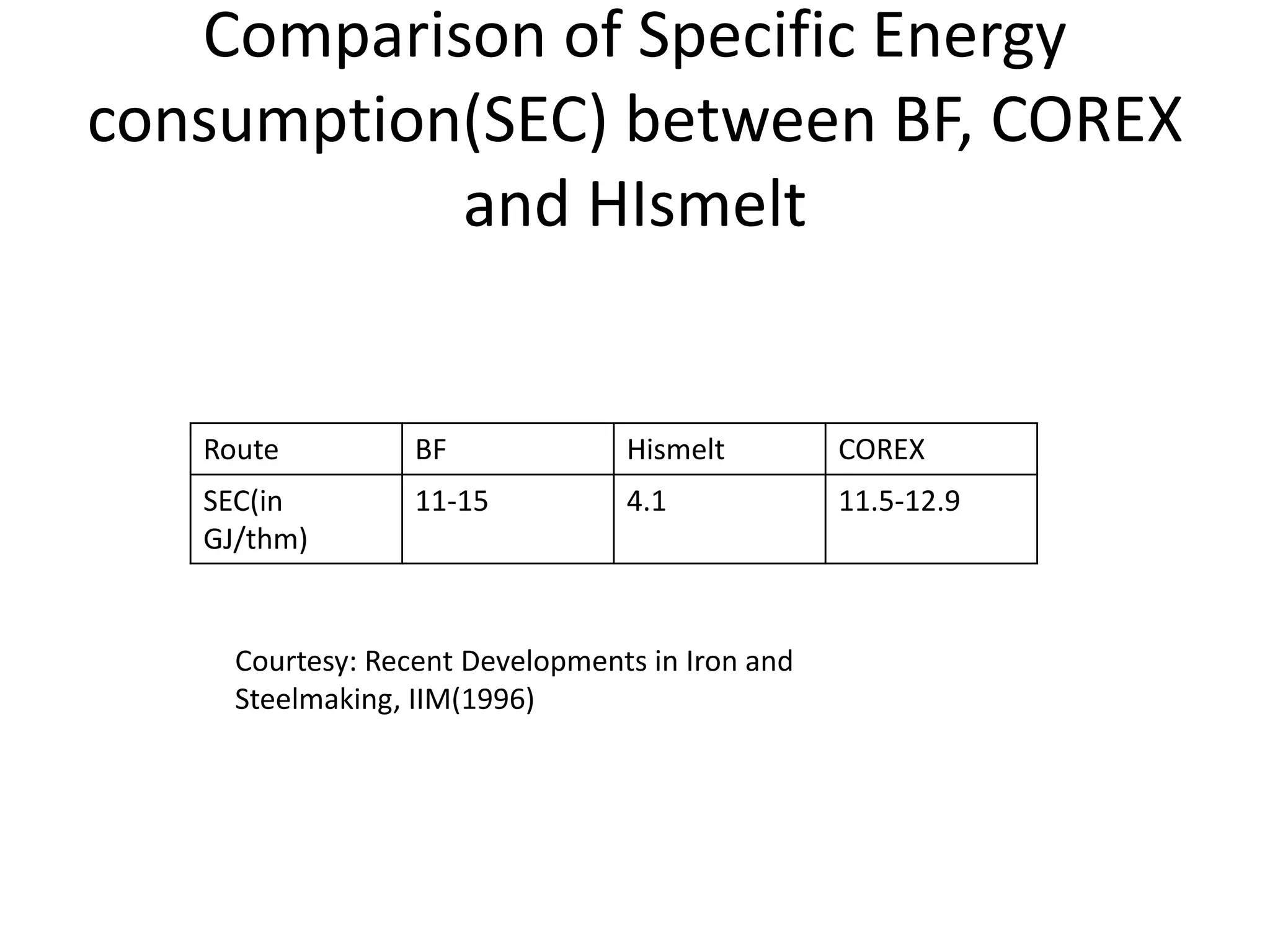

- The process has lower specific energy consumption and oxygen demand than blast furnaces or CO