Embed presentation

Downloaded 255 times

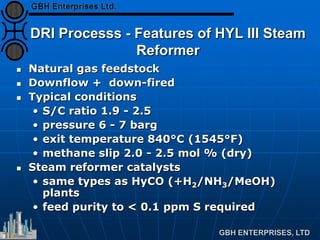

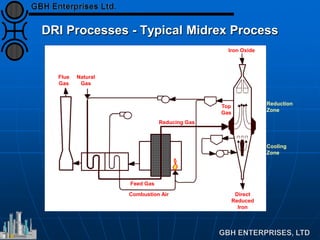

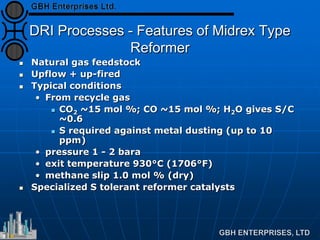

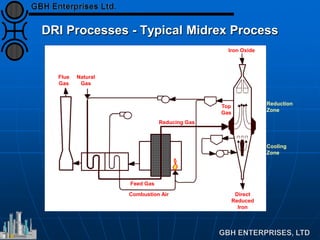

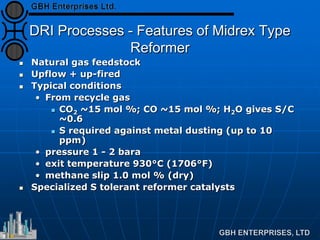

The document outlines the various direct reduced iron (DRI) plant flowsheet options, detailing the HYL and MIDREX types. It provides specific features and conditions for each process, such as feedstock, pressures, exit temperatures, and catalyst requirements. Key distinctions between the HYL III and MIDREX processes are also highlighted, focusing on their configurations and operational parameters.