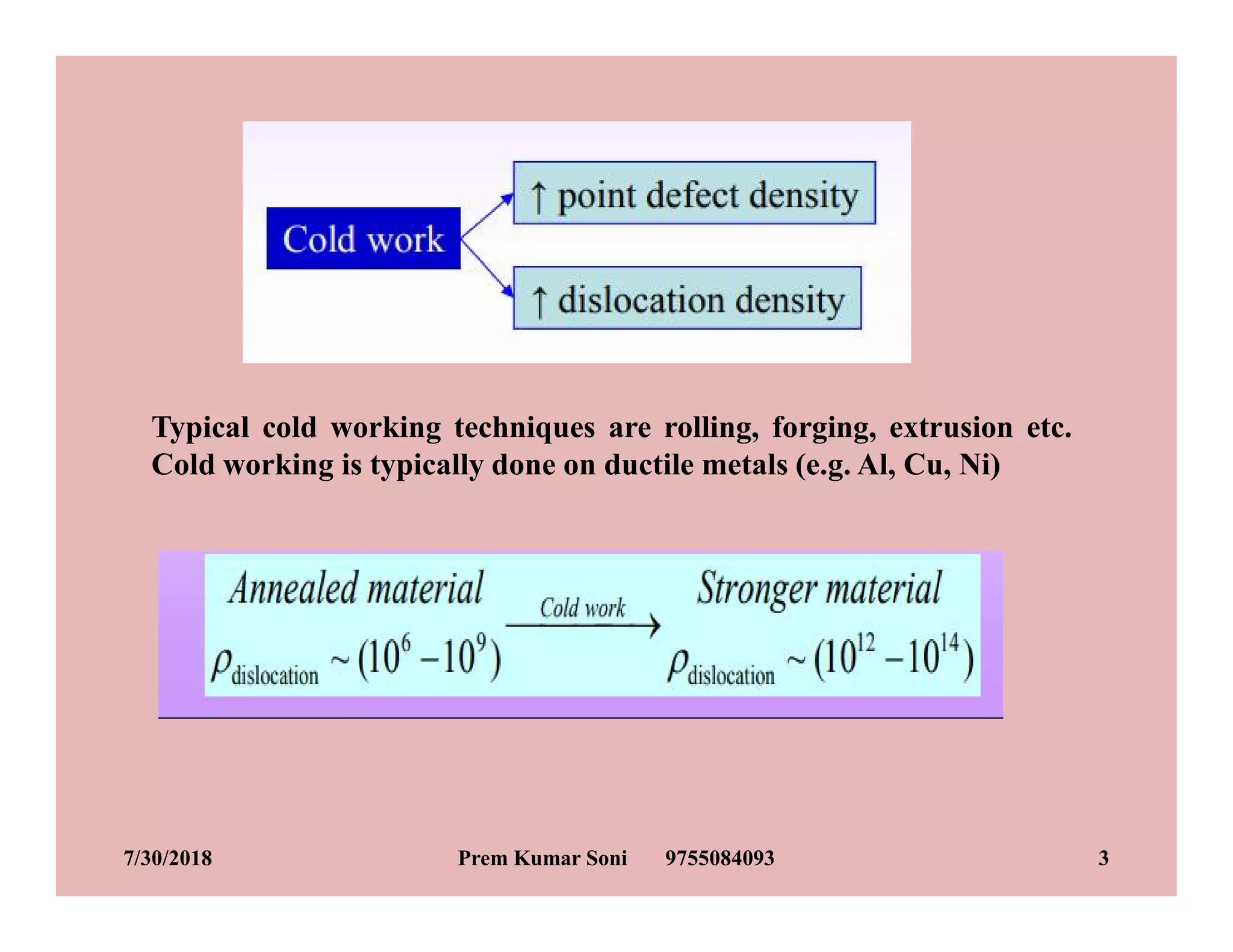

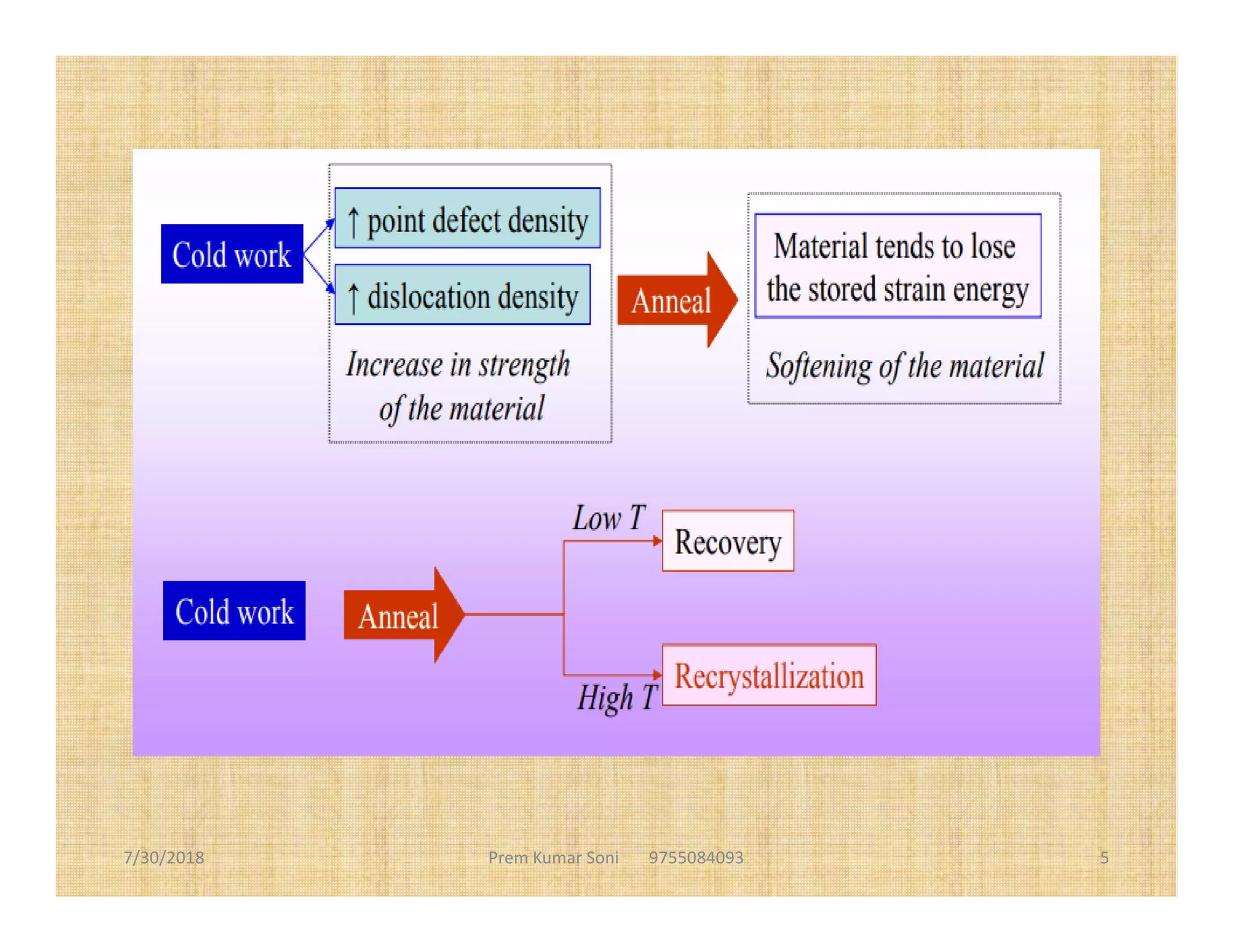

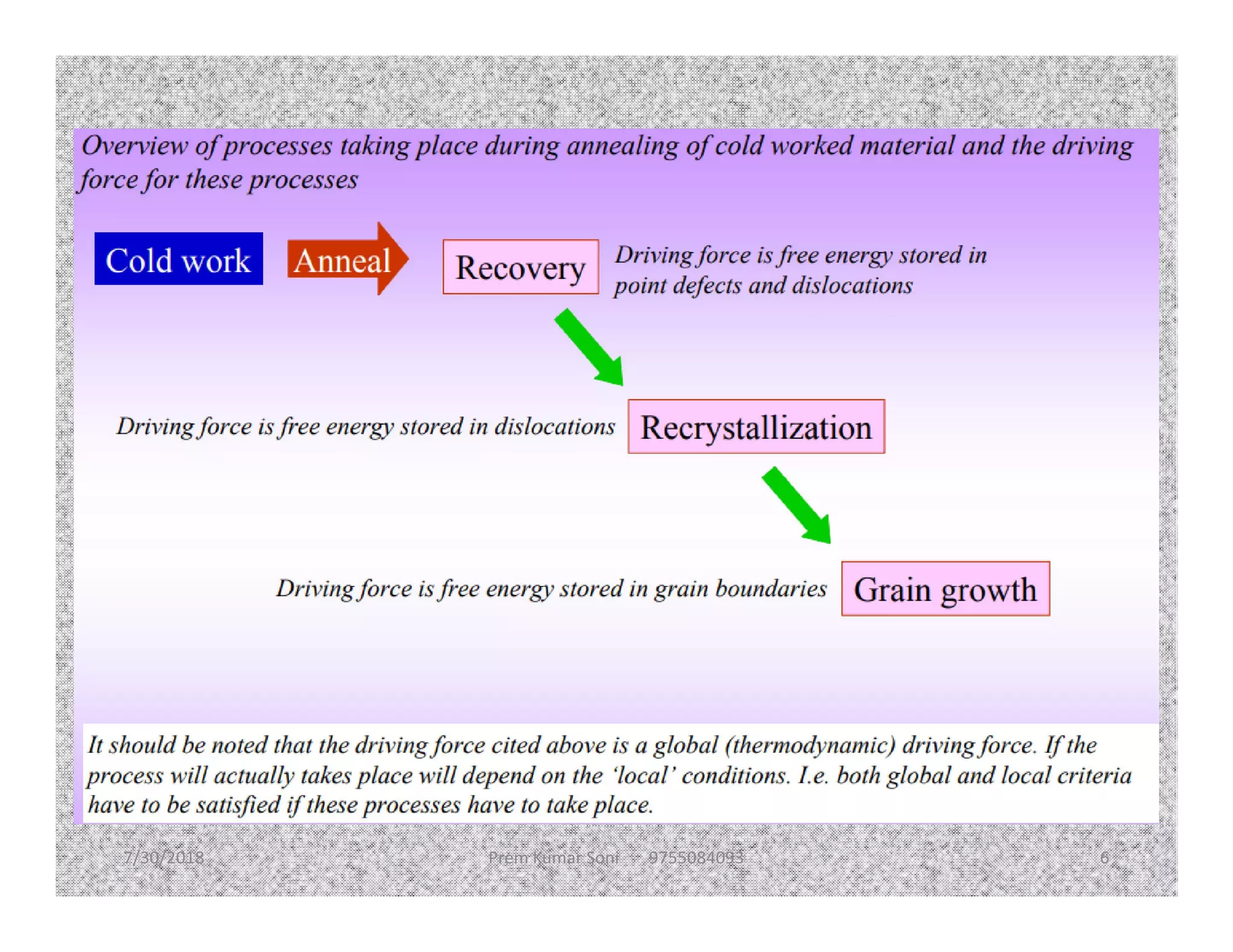

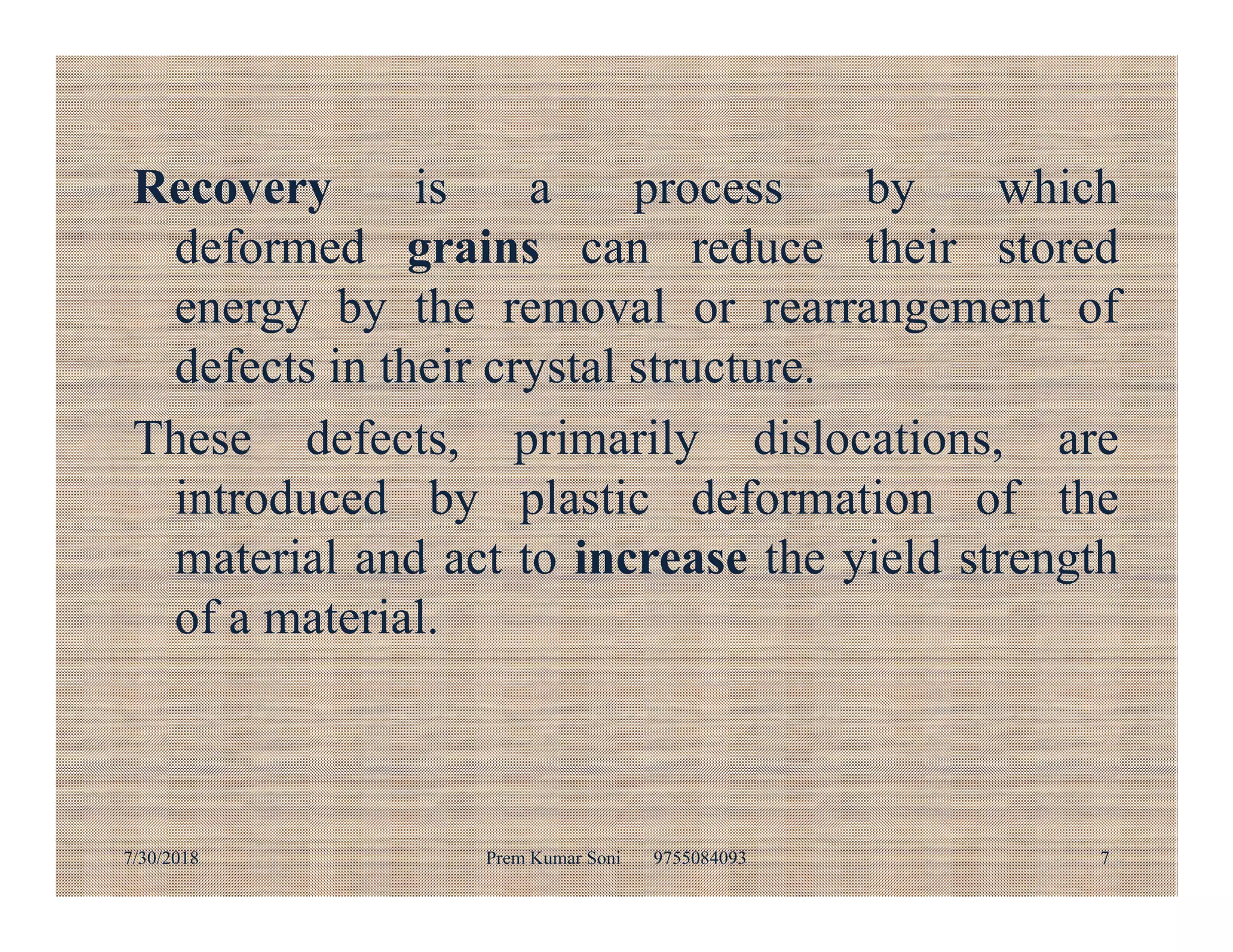

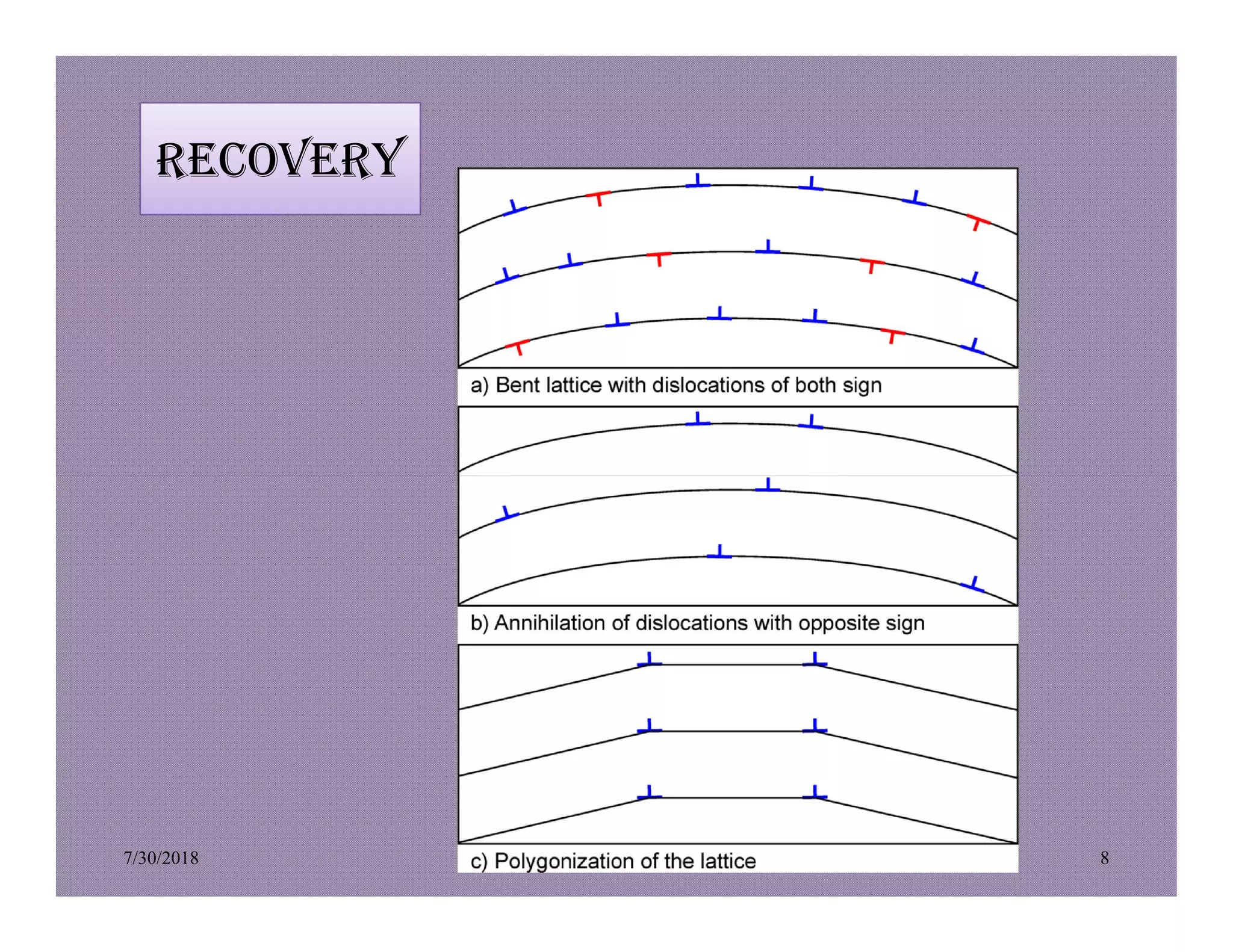

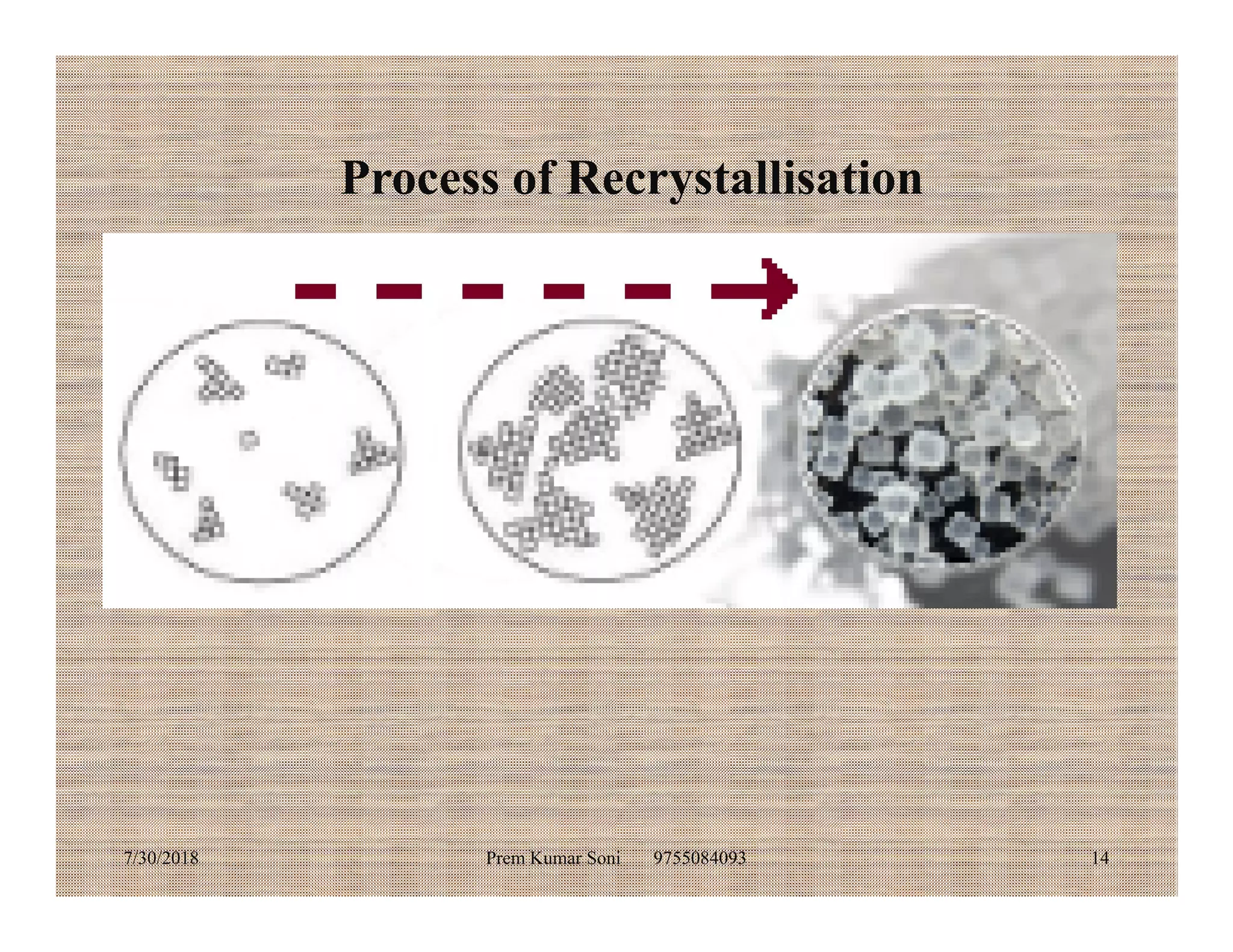

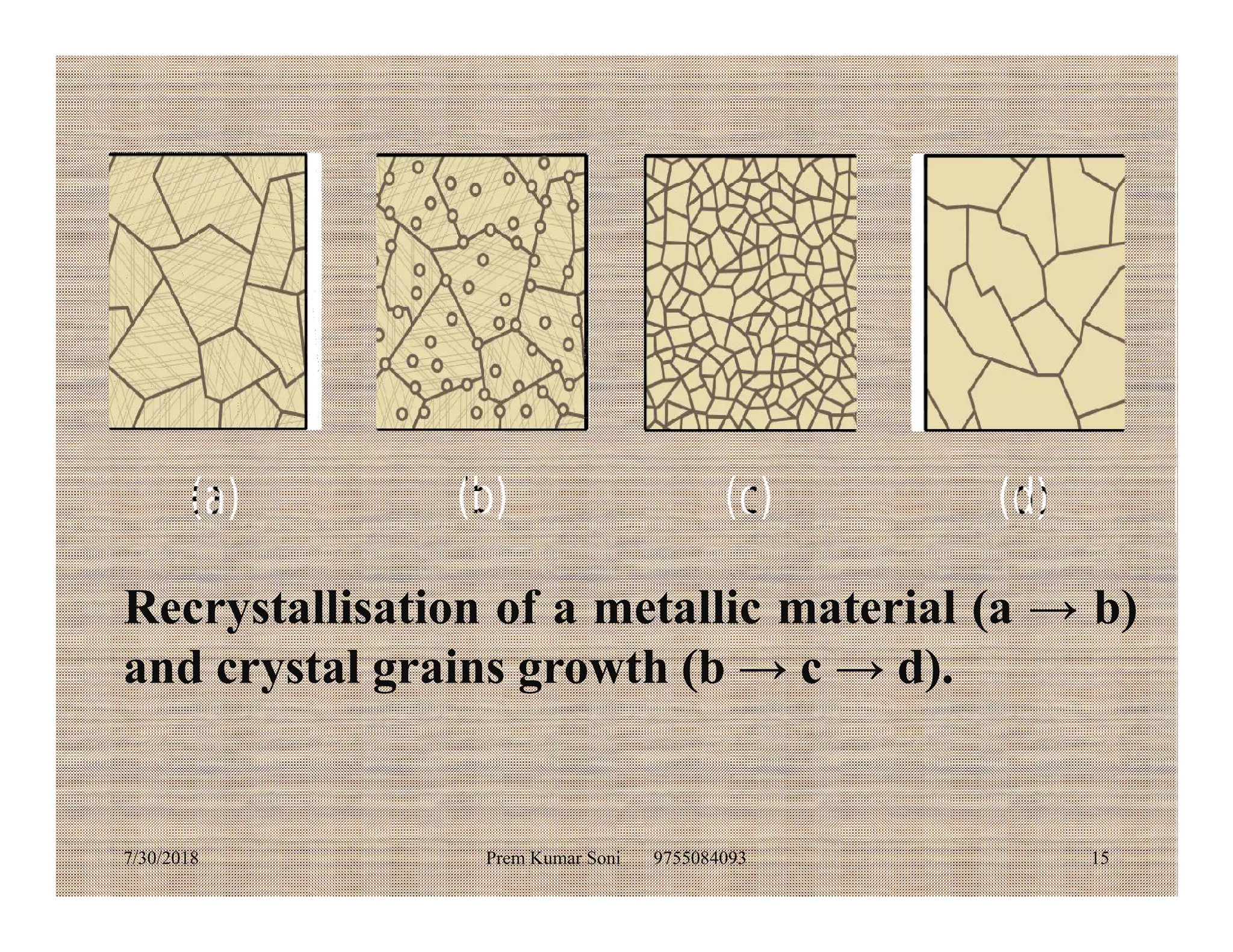

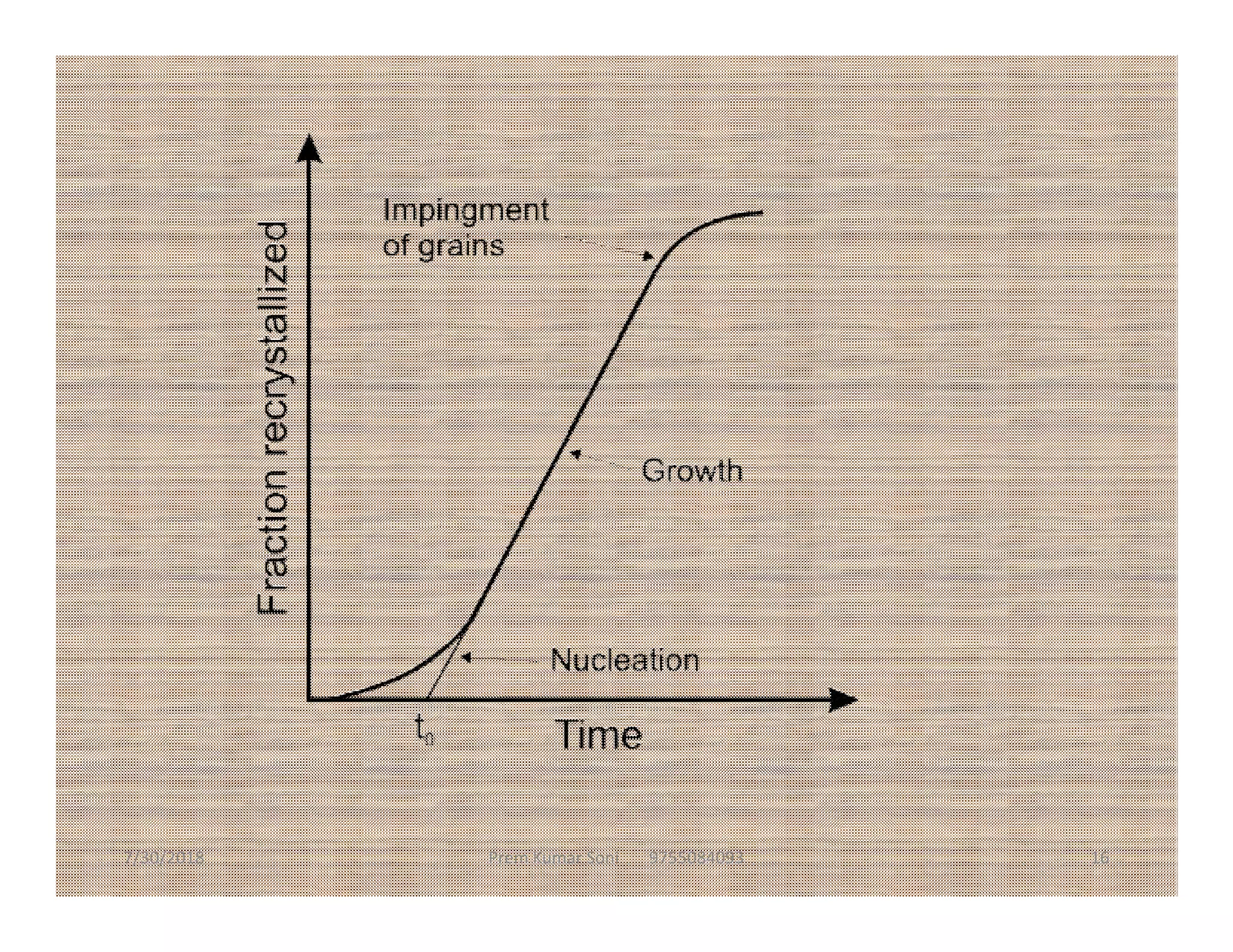

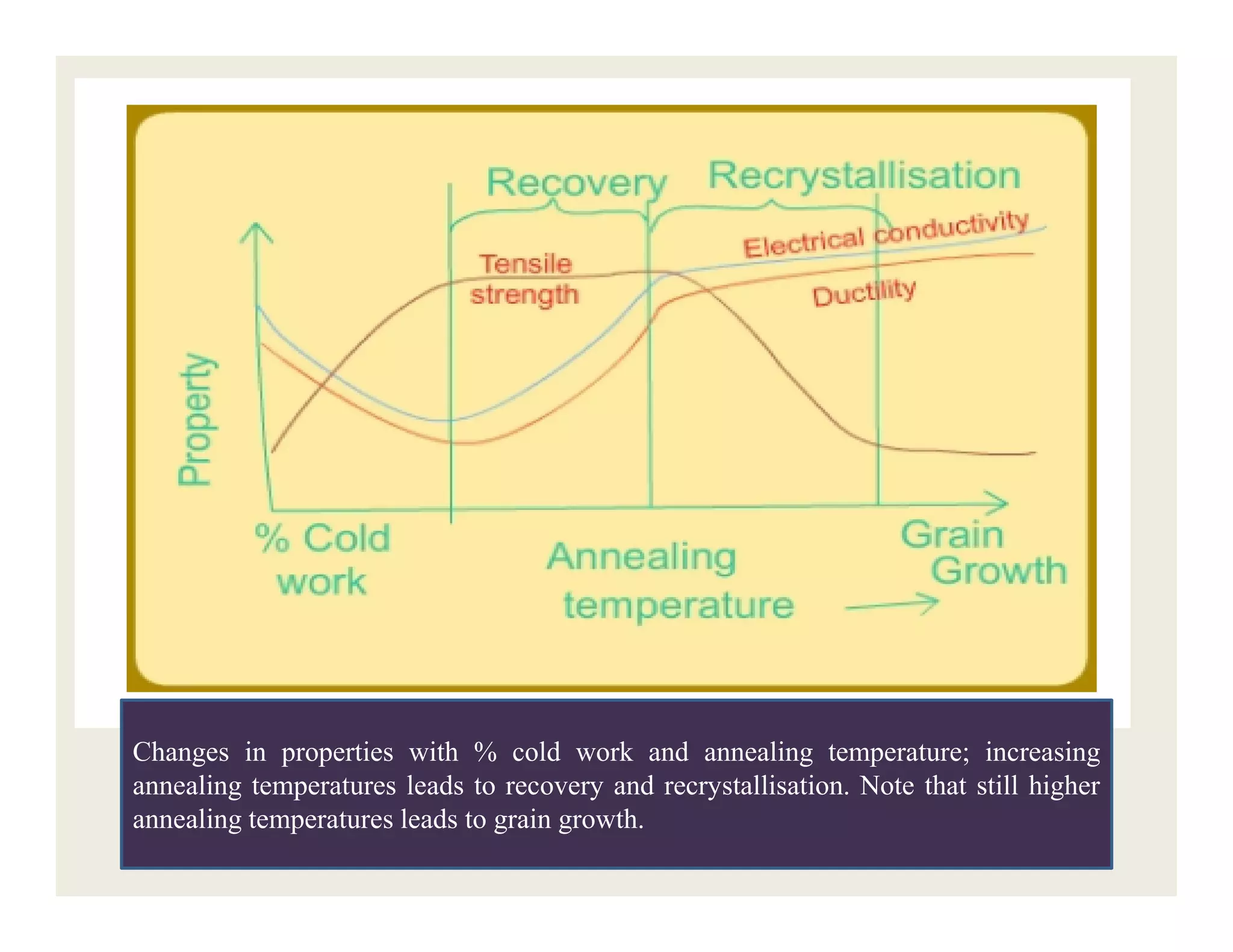

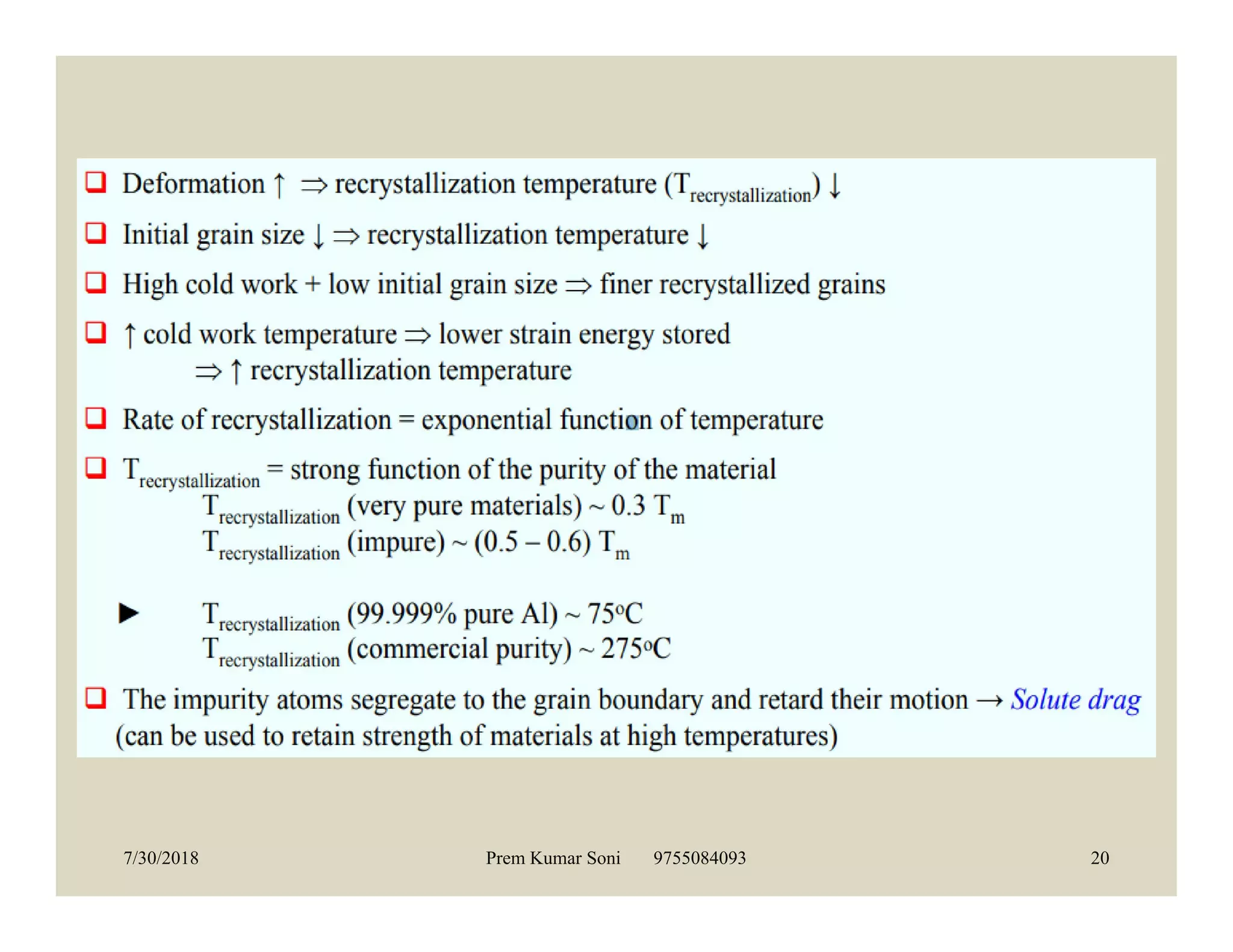

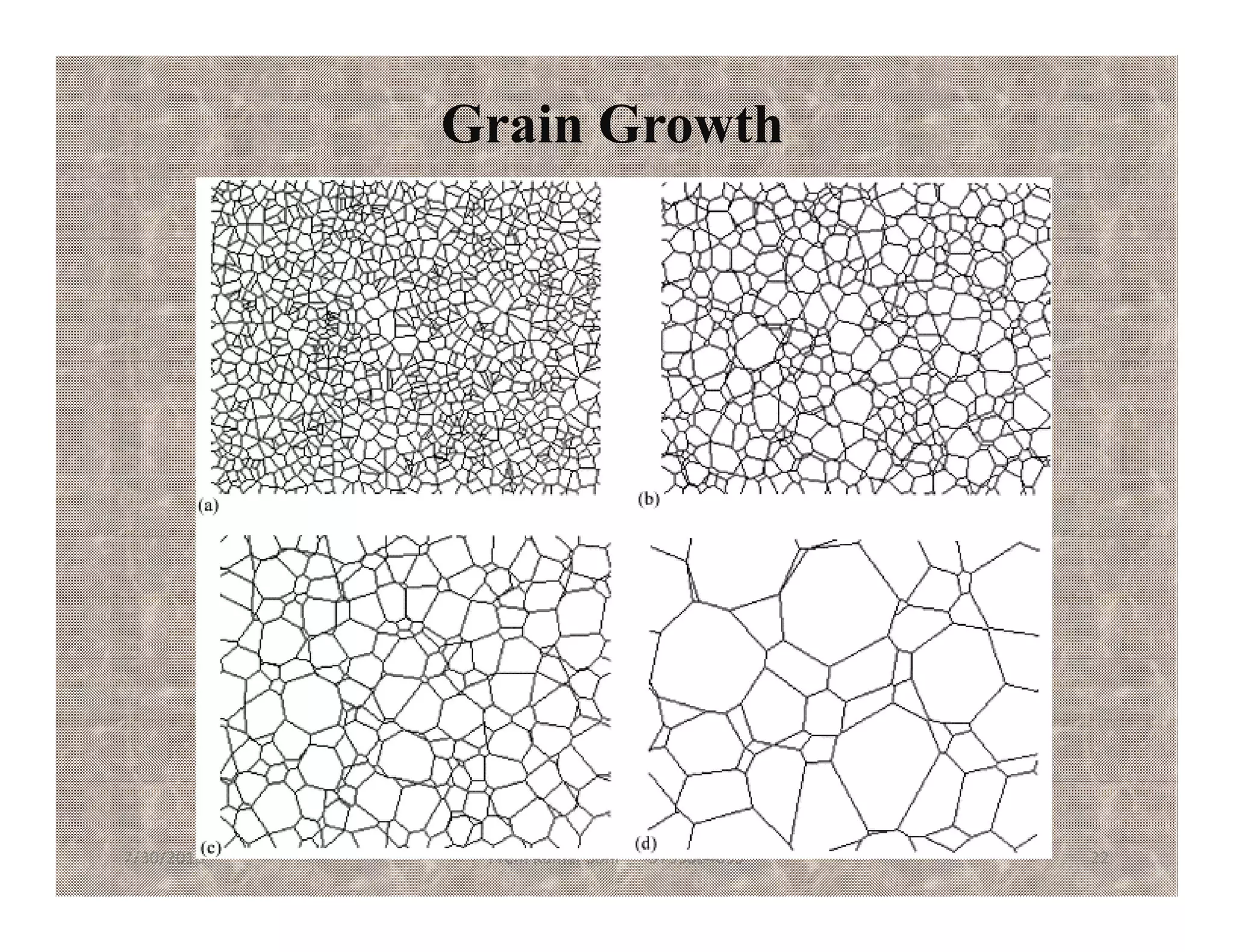

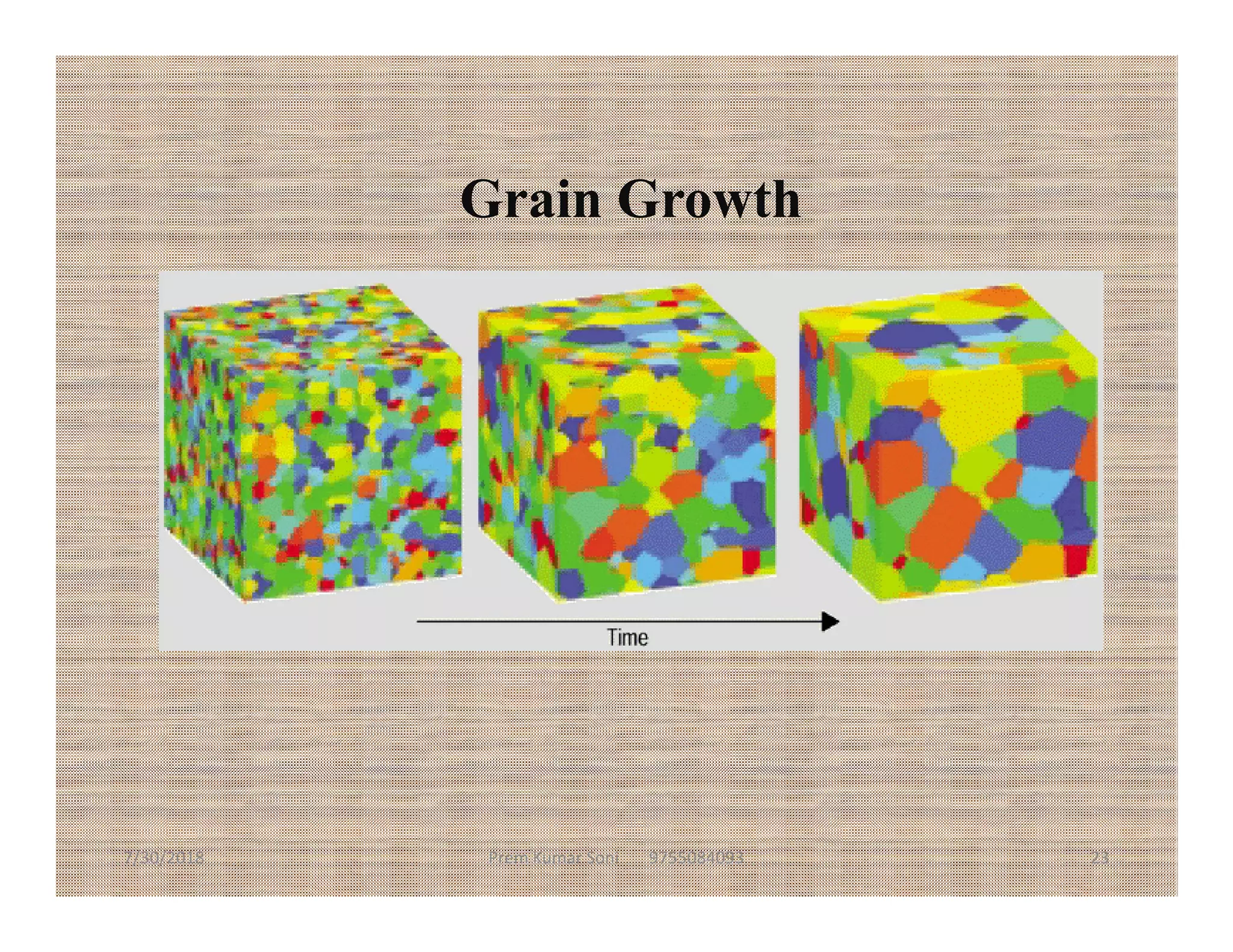

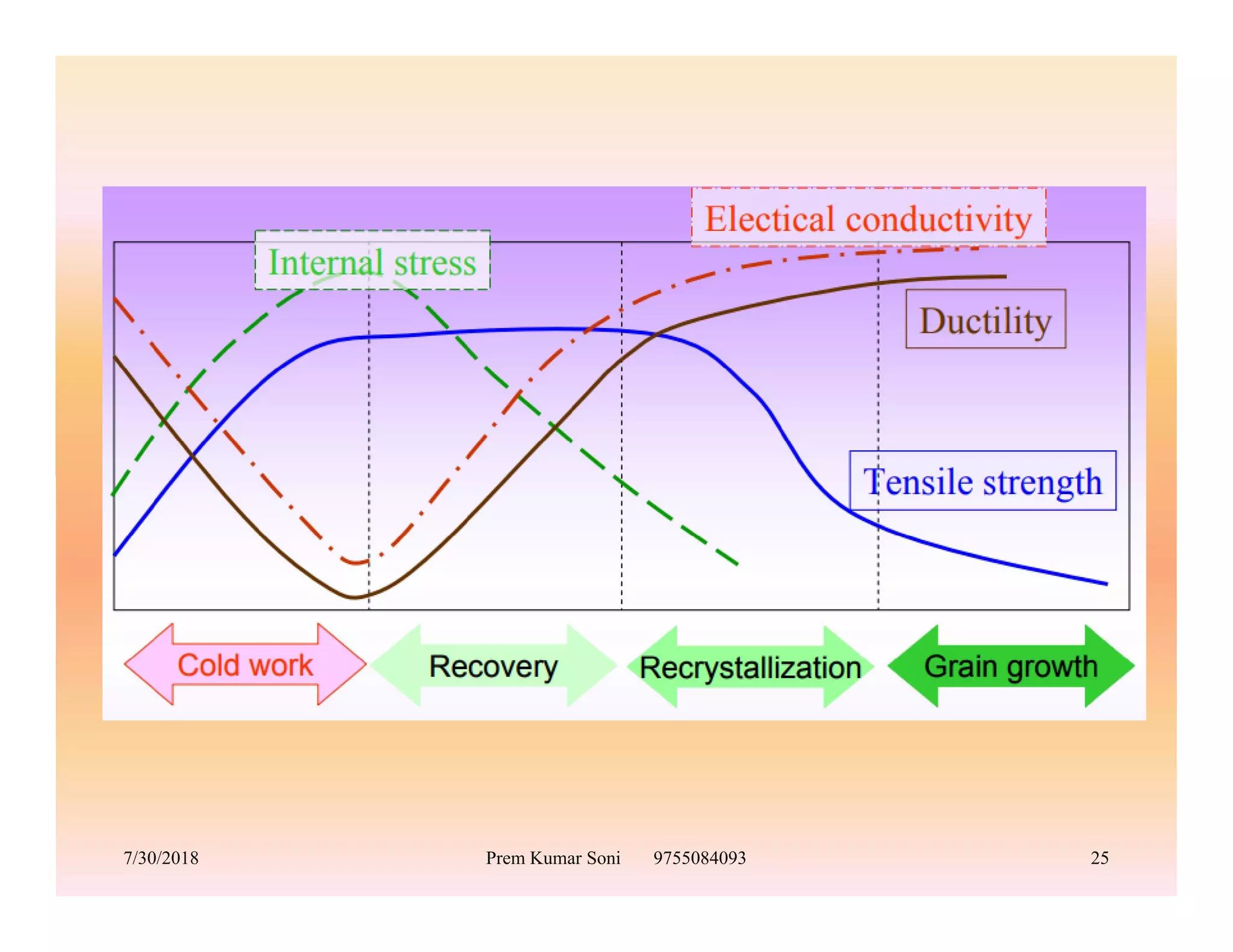

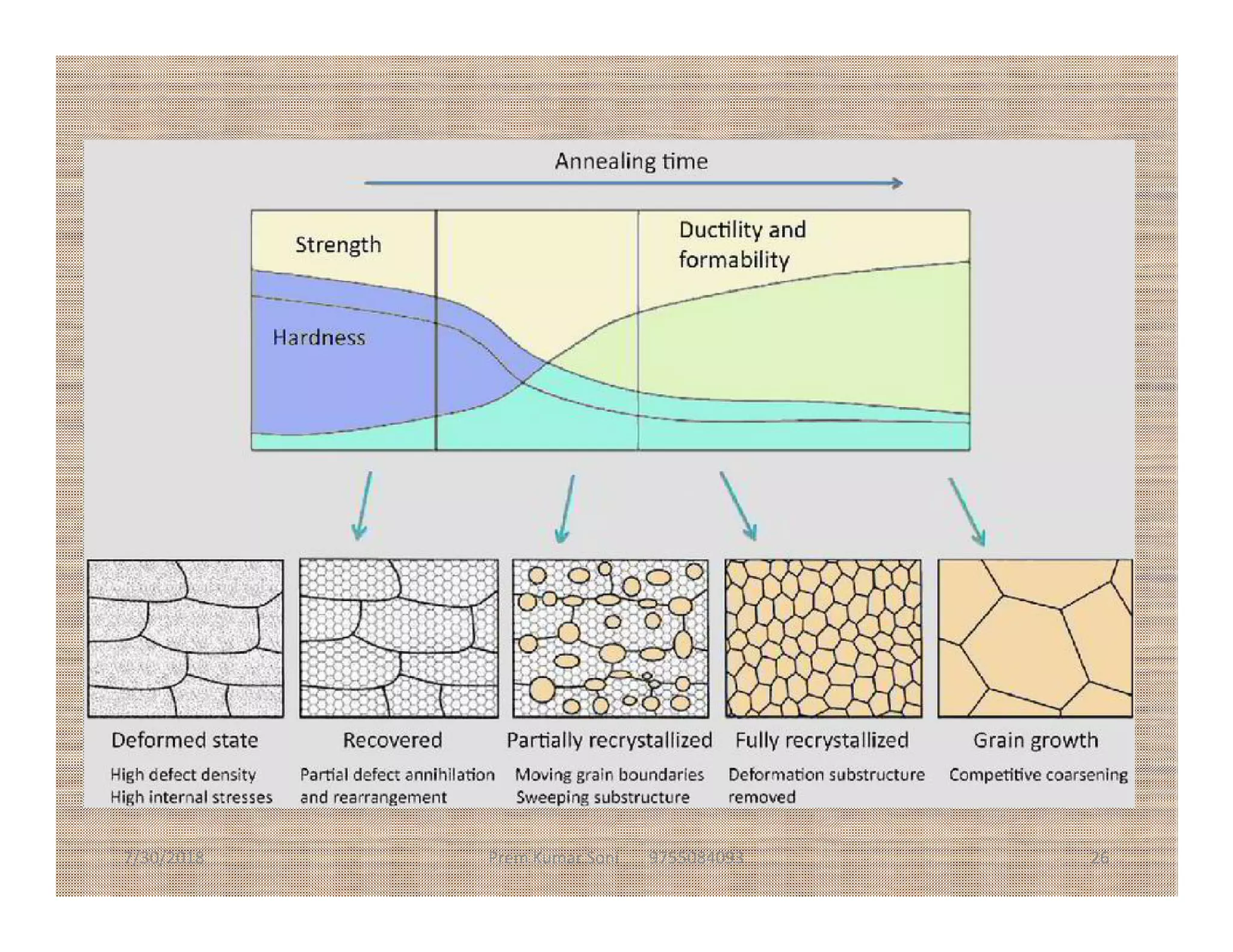

The document discusses the concepts of cold work, recovery, recrystallization, and grain growth in metals. Cold work increases strength and hardness but reduces ductility, while recovery involves the rearrangement of defects at low temperatures. Recrystallization replaces deformed grains with strain-free grains, and grain growth occurs when recovery and recrystallization are completed at high temperatures.