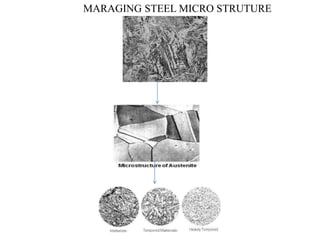

Maraging steels are low-carbon, highly alloyed steels with compositions of 18% nickel and 7% cobalt and less than 0.05% carbon. They develop martensite upon air quenching from the austenitizing temperature of 723°C, and precipitation hardening is done to achieve very high tensile strength. Maraging steels offer good machinability, weldability, and dimensional stability, with applications including shafts, barrel for firing guns, dies in casting, and components subject to impact fatigue.