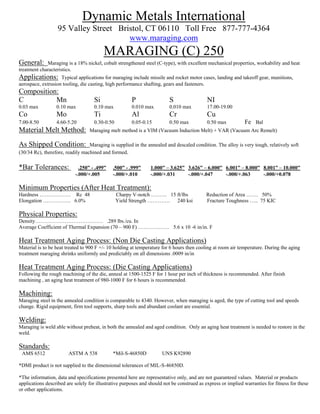

Dynamic Metals International produces MARAGING (C) 250, a nickel and cobalt strengthened steel alloy with excellent mechanical properties. Typical applications include aerospace, missile and rocket motor cases. The alloy has a composition of 0.03% carbon, 17-19% nickel, 7-8.5% cobalt, and 4.6-5.2% molybdenum. As shipped, the alloy is supplied in an annealed and descaled condition, making it readily machined and formed. After heat treatment, the alloy has a minimum hardness of Rc 48 and fracture toughness of 75 KIC.