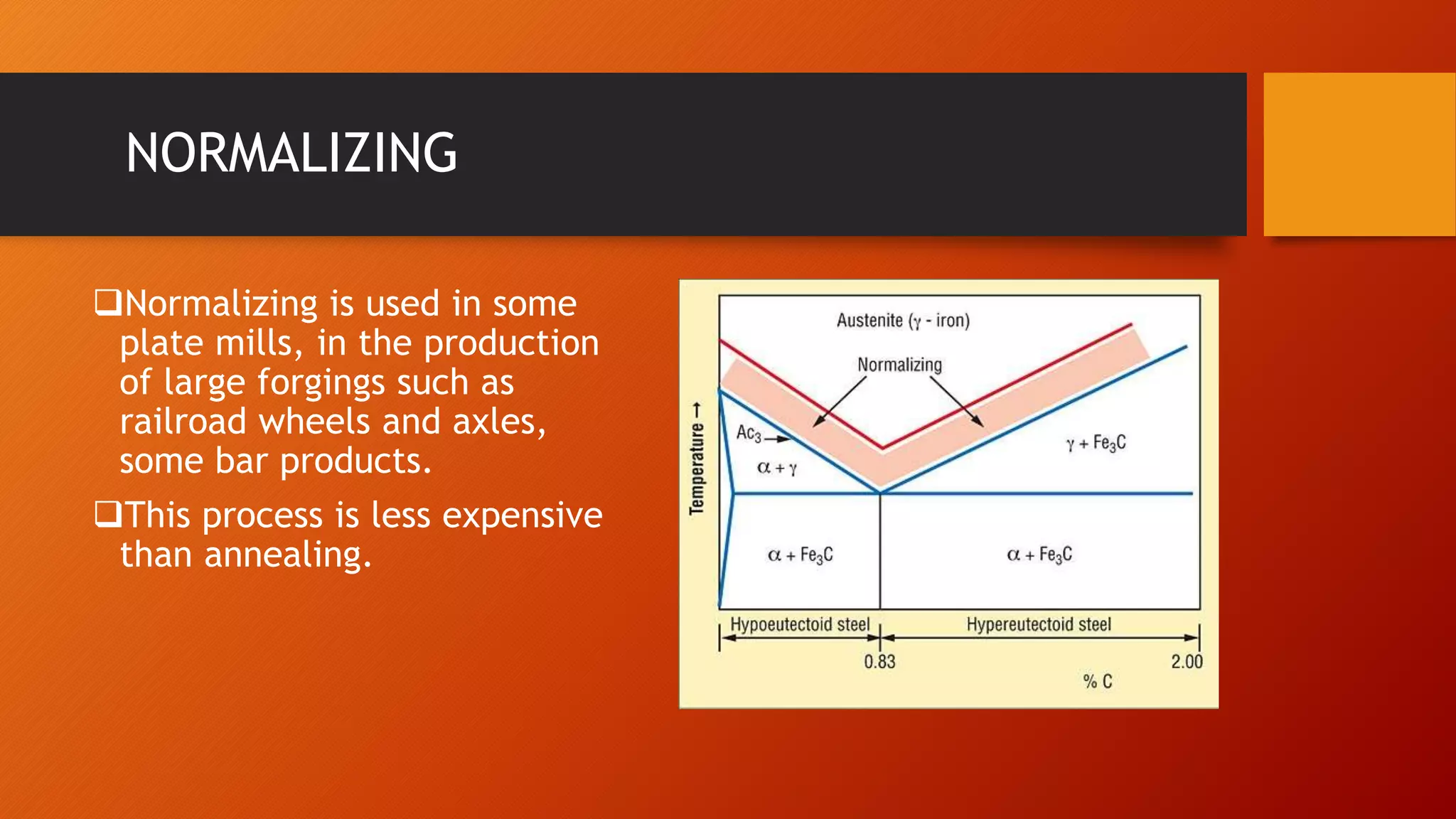

Heat treatment is a series of processes involving heating and cooling metals to change their mechanical properties. It can make metals harder, stronger, and more resistant to wear or softer and more ductile. Common heat treatment processes include annealing to soften metals, normalizing to relieve stresses, hardening to increase strength, tempering to reduce brittleness caused by hardening, and surface hardening methods like carburizing and nitriding to harden just the surface.