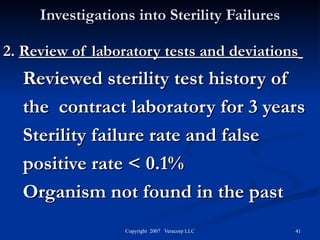

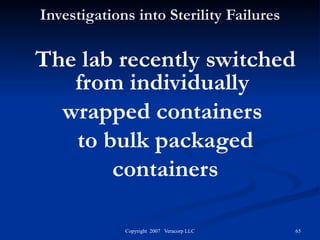

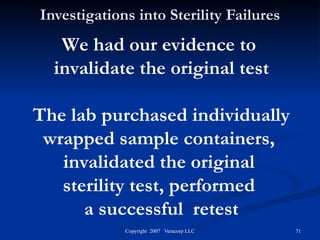

The document discusses investigations into a failed sterility test of a product. It describes the perspectives and concerns of different stakeholders when a sterility failure occurs, including the technician, lab director, quality assurance, manufacturer, and client. It then details the steps of a thorough investigation conducted by an expert to find the root cause, involving reviewing laboratory and production records, environmental monitoring data, personnel training, and sources of raw materials. The investigation found the likely cause was contamination from cardboard boxes used to package sterile containers in the laboratory rather than any issues with production, raw materials, or personnel.

![Investigations into Sterility Failures Thank you Frank Settineri Veracorp LLC 973-729-8171 [email_address]](https://image.slidesharecdn.com/InvestigationsintoSterilityFailures-12327231887-phpapp03/85/Investigations-Into-Sterility-Failures-75-320.jpg)