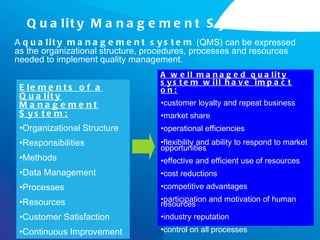

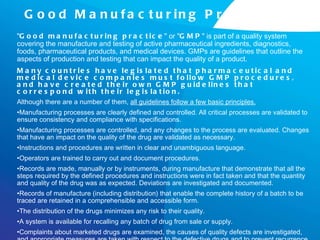

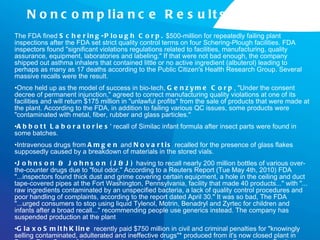

The document discusses quality management systems (QMS) and good manufacturing practices (GMP) and their benefits for businesses. It provides an overview of the key elements of a QMS and explains that a QMS establishes procedures and processes to ensure quality control across all aspects of a business. It then describes GMP guidelines which outline manufacturing and testing standards for pharmaceuticals and medical devices to ensure product quality and compliance. The document notes that many countries have legislation requiring companies to follow GMP procedures.