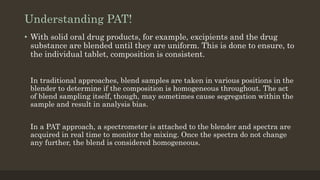

Process Analytical Technology (PAT) is defined by the FDA as a system for designing and controlling manufacturing processes to ensure final product quality through timely measurements. Although it aims to support innovation and efficiency in pharmaceutical development, its implementation in the industry has been slow due to regulatory uncertainties and challenges. PAT offers numerous benefits including real-time quality assurance, reduced waste, and improved understanding of manufacturing processes.