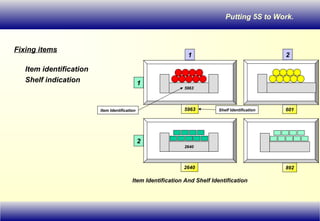

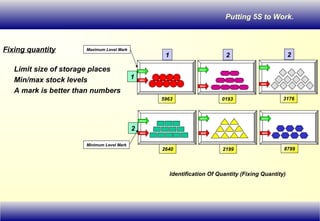

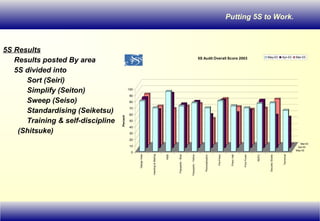

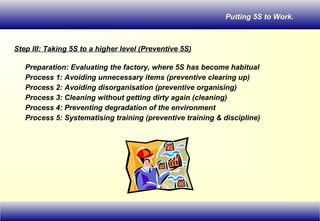

The document discusses the 5S methodology for improving organization and housekeeping in the workplace. It describes the 5 pillars of 5S - Sort, Simplify, Sweep, Standardize, and Sustain. The 5S approach involves initially sorting through all items to remove unnecessary items, organizing the workspace to establish storage locations, sweeping to clean the area daily, standardizing processes to maintain organization, and sustaining practices through training and commitment. Implementing 5S is presented as a 3 step process of initially cleaning up, then making organization a habit, and ultimately preventing issues through a more preventative approach. Audit checklists are provided to evaluate effectiveness. Overall the document provides an overview of the 5S methodology.