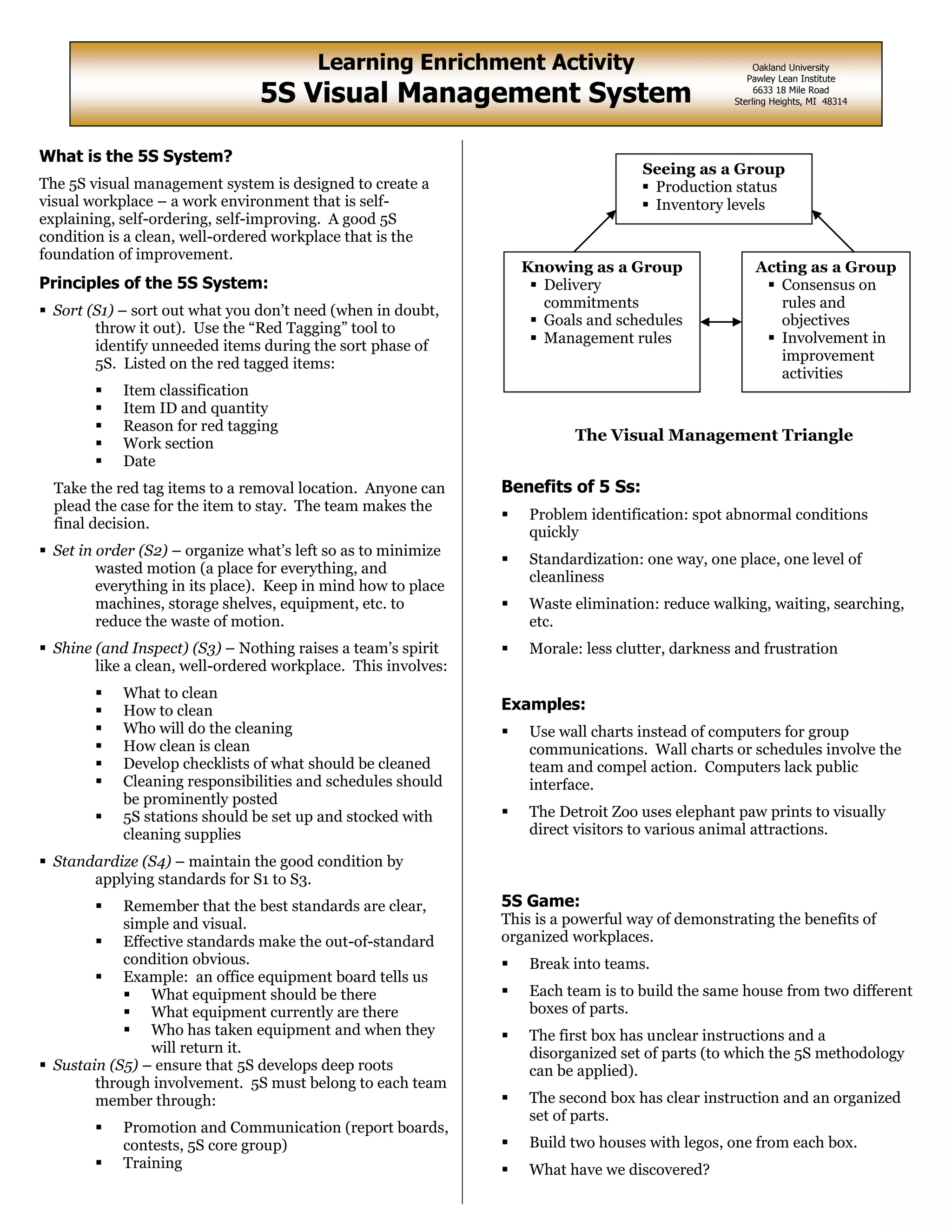

The document discusses the 5S visual management system, which is designed to create a clean and well-organized workplace. It has five principles: sort, set in order, shine, standardize, and sustain. Implementing 5S brings benefits like easier problem identification, standardized processes, and reduced waste. An example activity involves having teams build houses from Lego parts that are either disorganized or organized to demonstrate the impact of 5S.