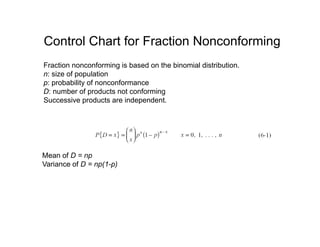

This document discusses control charts for attributes, including fraction nonconforming charts and control charts for nonconformities (defects). It covers key aspects such as:

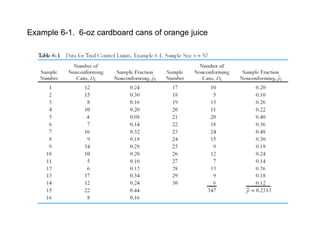

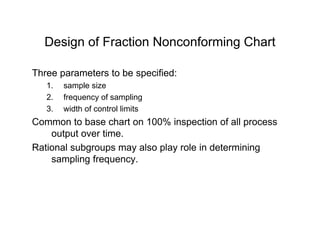

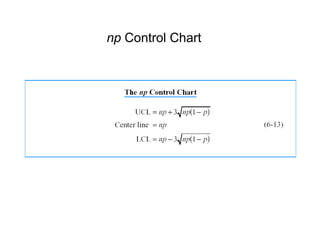

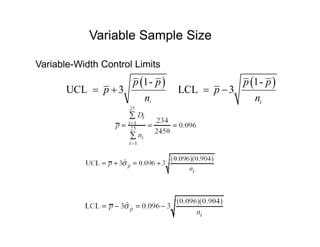

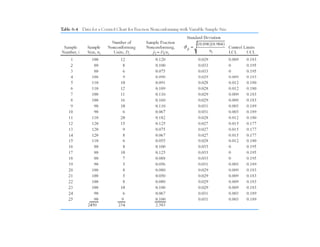

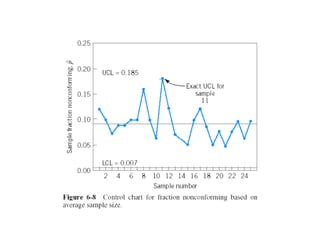

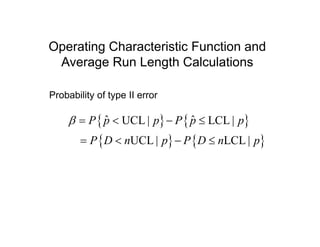

1. The parameters, formulas, and design of fraction nonconforming charts, including sample size, frequency of sampling, and control limit width.

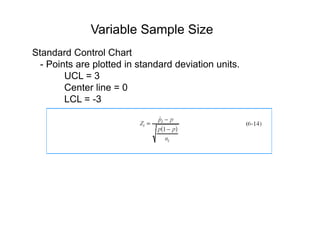

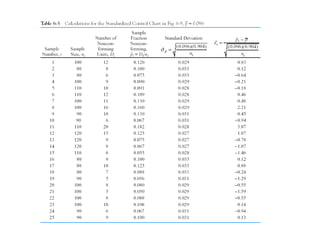

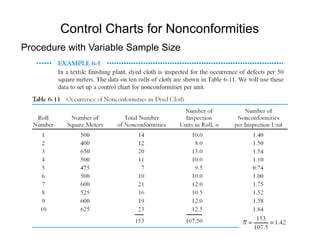

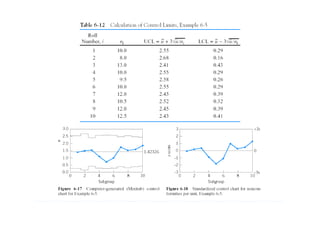

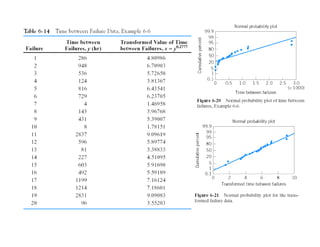

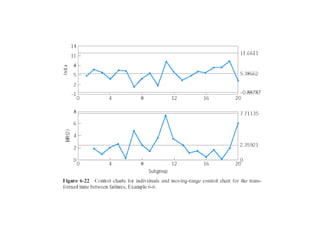

2. Procedures for control charts with constant and variable sample sizes, and how to estimate parameters if a standard is not given.

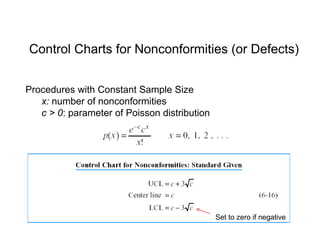

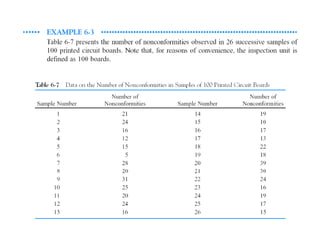

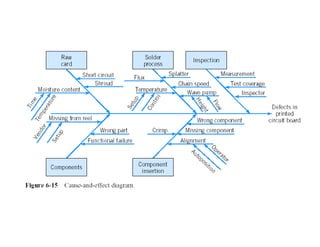

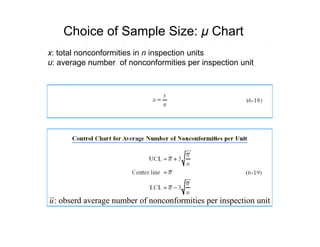

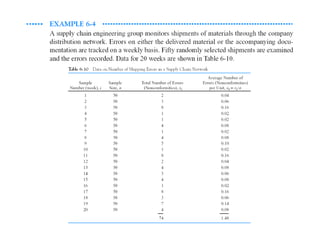

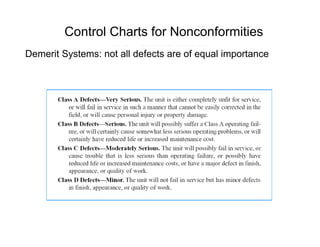

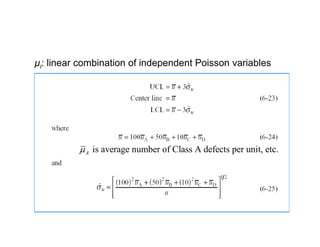

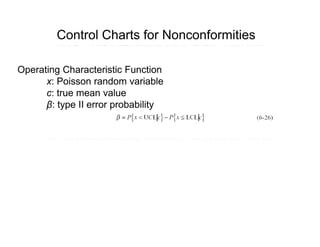

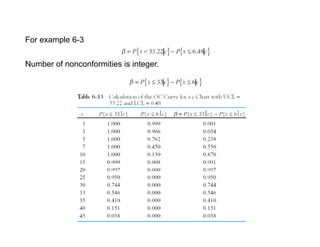

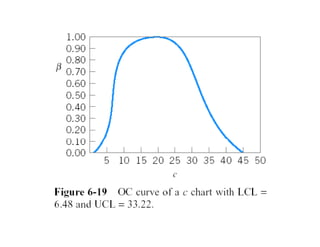

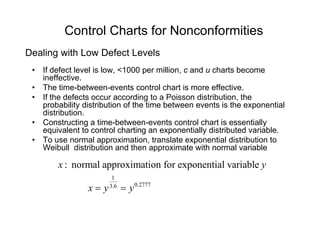

3. How to construct control charts to monitor nonconformities using variables like number of defects, demerit points, and Poisson distributions.

4. Guidelines for implementing control charts and determining which characteristics and processes to monitor.