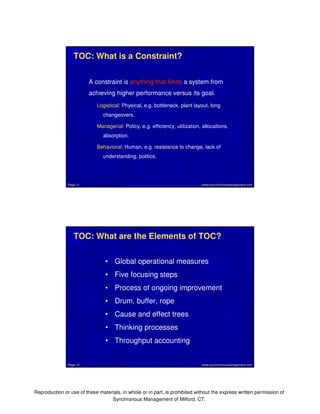

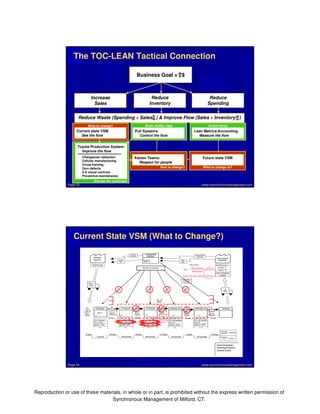

The document discusses the relationship between the Theory of Constraints (TOC) and Lean Manufacturing. It defines basic TOC concepts and explores how TOC and Lean can be synergistic. The key connection is that TOC aims to increase throughput and reduce inventory and expenses, while Lean seeks to reduce waste and improve flow, which supports the TOC goals. Applying both approaches together can help organizations maximize profits through continuous improvement efforts.