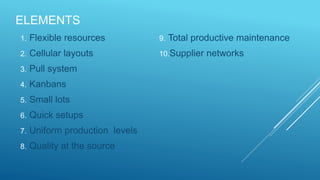

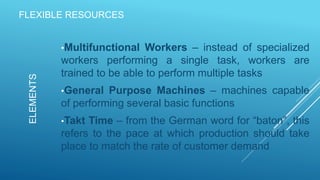

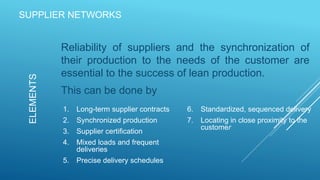

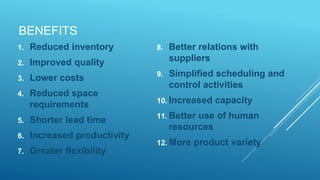

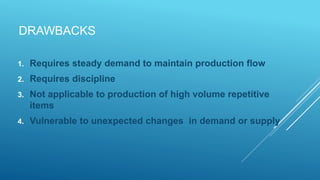

Lean production is a systematic method to eliminate waste from manufacturing. It identifies seven types of waste including transportation, inventory, unnecessary movement, waiting, overproduction, overprocessing, and defects. The key elements of lean production include flexible resources, cellular layouts, a pull system using kanbans, small lot sizes, quick changeovers, uniform production levels, quality at the source, and total productive maintenance. Implementing these elements can help reduce costs and inventory while improving quality, productivity, and flexibility. However, lean production requires steady demand and discipline.