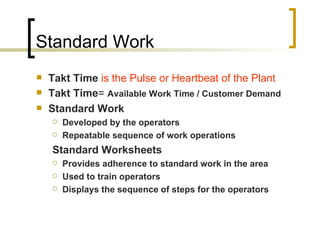

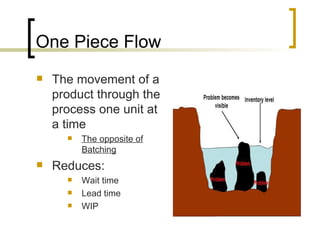

Lean manufacturing aims to eliminate waste through standard work and one-piece flow. Standard work establishes repeatable work sequences defined by operators. One-piece flow moves individual products continuously through processes to reduce wait time, lead time, and work-in-progress inventory. The benefits of one-piece flow include improved safety, quality, flexibility, productivity, and employee morale.