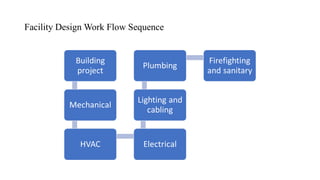

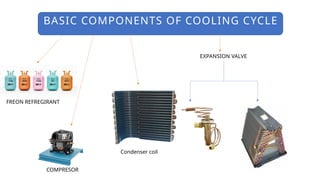

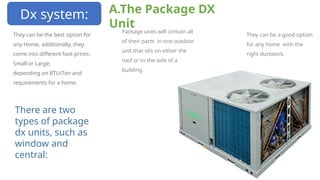

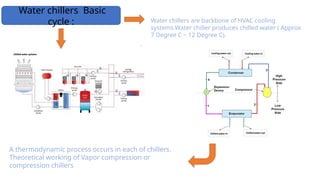

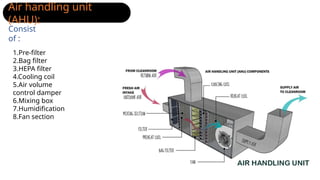

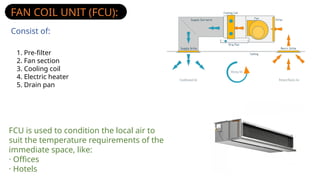

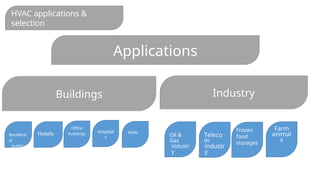

The document presents a comprehensive study on HVAC design, installation, and troubleshooting focusing on water-cooled chiller systems, cooling towers, and air handling units, as well as the various HVAC system types. It details the objectives of an internship program that aims to provide practical experience and knowledge in HVAC systems, identifying components and functions necessary for effective installation and maintenance. Additionally, it outlines the services and achievements of Utility Professionals, an engineering organization specializing in MEP design and consultancy across various sectors.