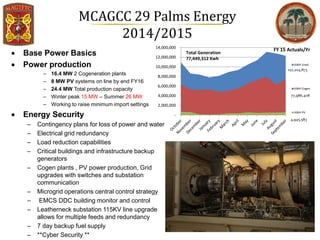

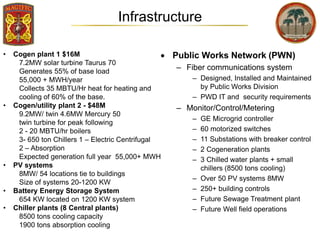

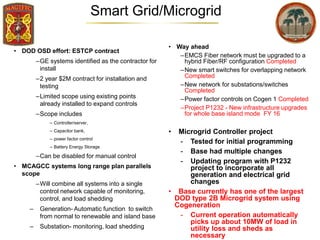

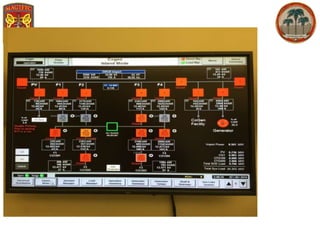

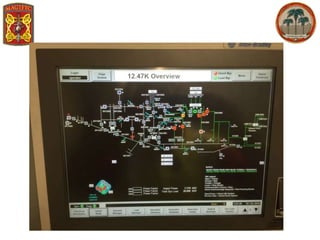

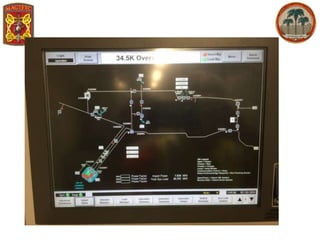

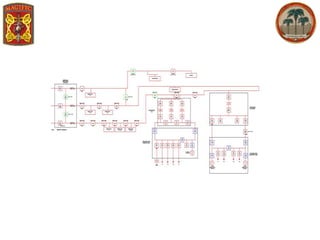

The document discusses the energy production capabilities and management systems of the MCAGCC 29 Palms microgrid, highlighting its total production capacity of 24.4 MW and critical infrastructure for energy security. It outlines details regarding cogeneration plants, photovoltaic systems, and backup capabilities, along with future plans for expanding and enhancing the microgrid's functionality. Key considerations include maintaining cybersecurity, personnel training, and implementing a simple, effective design for operational reliability.