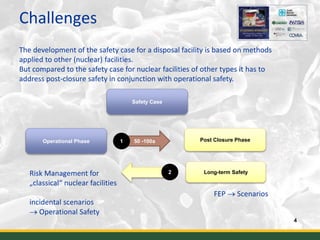

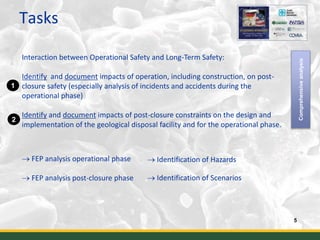

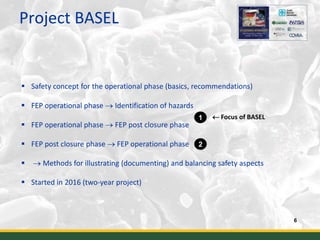

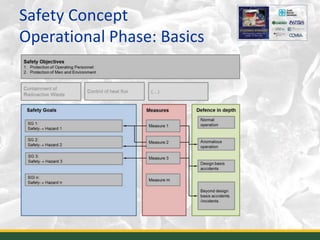

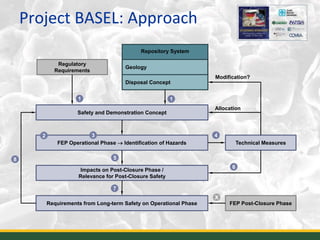

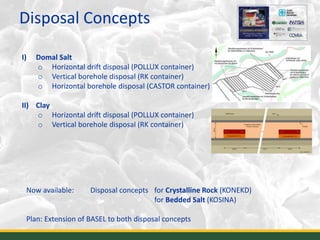

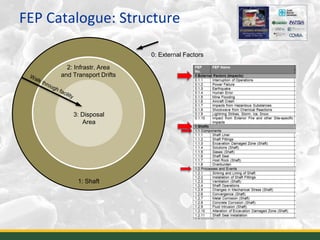

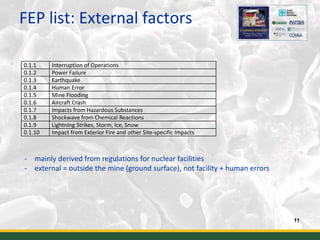

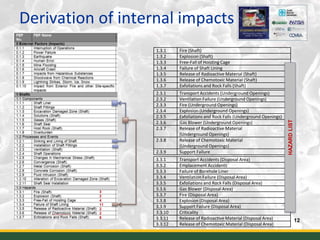

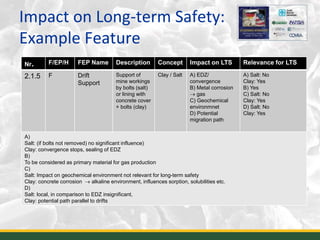

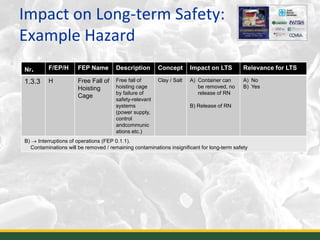

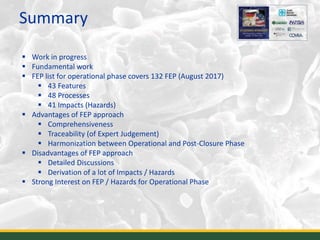

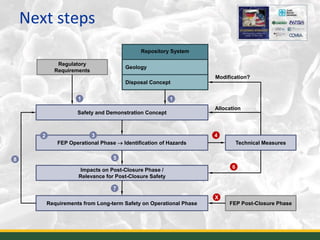

This document discusses the interaction between operational safety and long-term safety for geological radioactive waste repositories. It outlines challenges in developing a safety case that addresses both operational and post-closure phases. The project aims to identify impacts that operation may have on long-term safety and vice versa. This is done through a feature, event, and process catalog that identifies hazards during the operational phase and assesses their relevance for long-term safety. The work will help illustrate the balance and linkage between ensuring safety during facility operation and after closure.