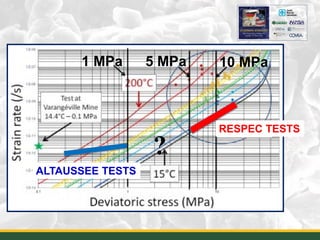

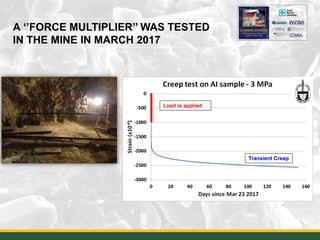

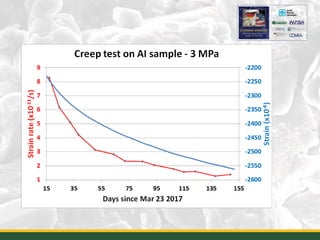

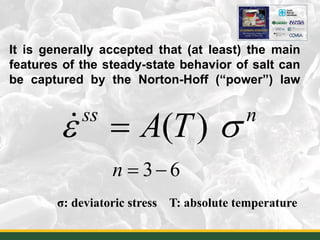

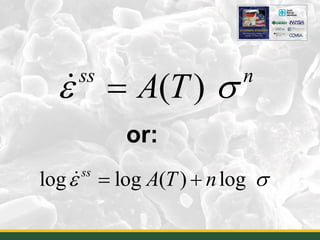

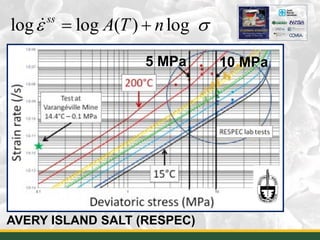

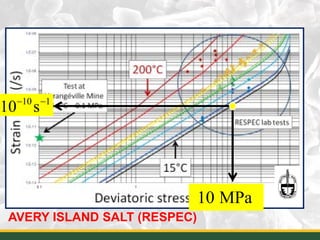

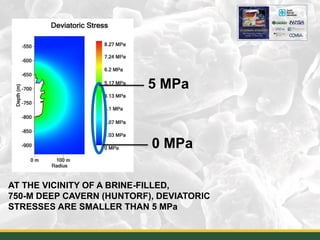

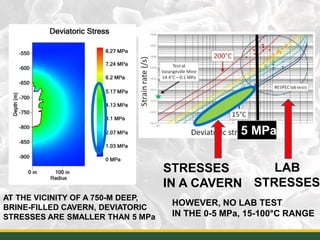

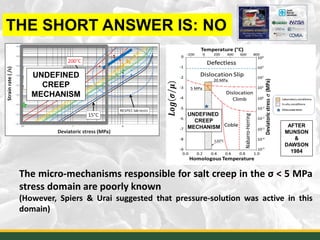

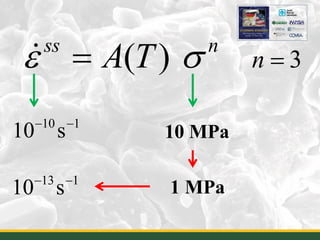

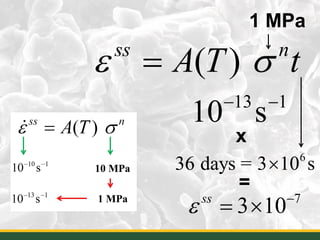

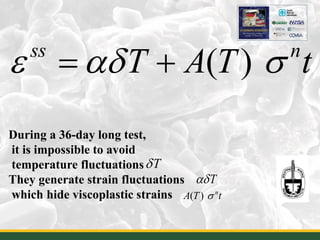

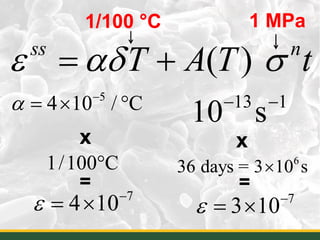

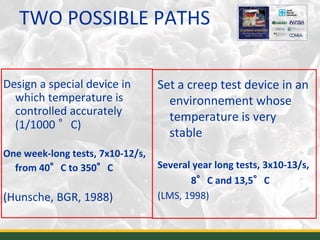

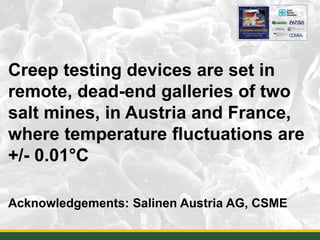

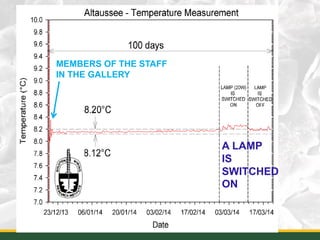

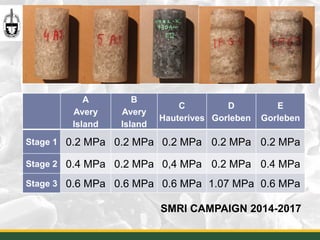

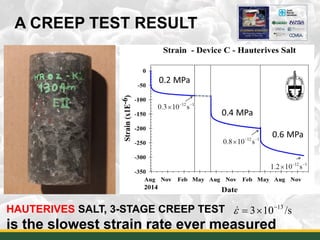

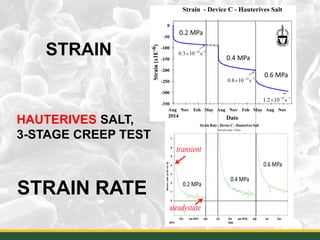

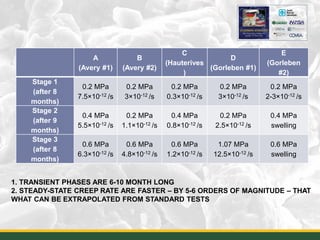

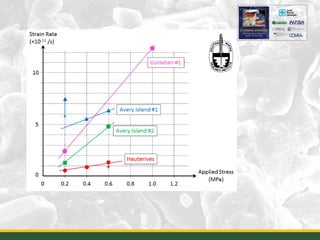

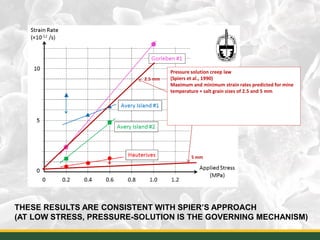

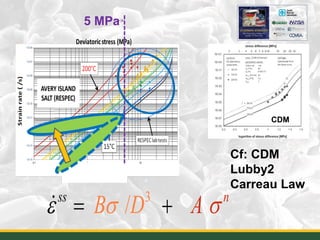

1. Very slow creep tests were conducted on salt rock samples in stable underground environments to obtain strain rates in the range of 10-13/s. This provides data in the very low stress range of 0-5 MPa that is representative of conditions near deep salt caverns, filling gaps in existing data.

2. The tests found transient creep phases lasting 6-10 months and steady-state creep rates 5-6 orders of magnitude faster than extrapolated from standard higher-stress tests. Results were consistent with models assuming pressure-solution creep at low stresses.

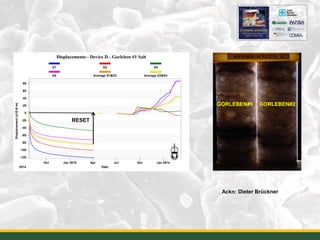

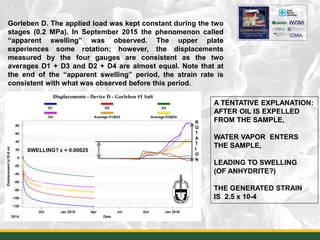

3. One sample showed apparent "swelling" after oil was found within it, possibly due to water vapor entry leading to strain in an

![43

GORLEBEN D1: AFTER A COUPLE OF

MONTHS, OIL WAS FOUND AT SAMPLE BOTTOM

“blocks of primary rock salt crystals, and shredded and

crushed fragments of anhydrite lines, float in a matrix of

recrystallized rock salt”; … “[hydrocarbons] appear mostly

in the form of streaks, dispersed clouds, clusters and islands.

.. hydrocarbons are located 1) along grain boundaries of

halite and/or anhydrite crystals 2) in newly formed artificial

microcracks due to drilling and preparation 3) in µcapillary

tubes of anhydrite crystals and 4) rarely in µ-porous parts of

the Hauptsalz … the content (up to several hundreds ppm) is

too low to affect the geomechanical behavior of rock salt.”

(Hammer et al., 2012)”.](https://image.slidesharecdn.com/09berestetal-170915181311/85/09-Invited-Lecture-Salt-Creep-at-Low-Deviatoric-Stress-43-320.jpg)