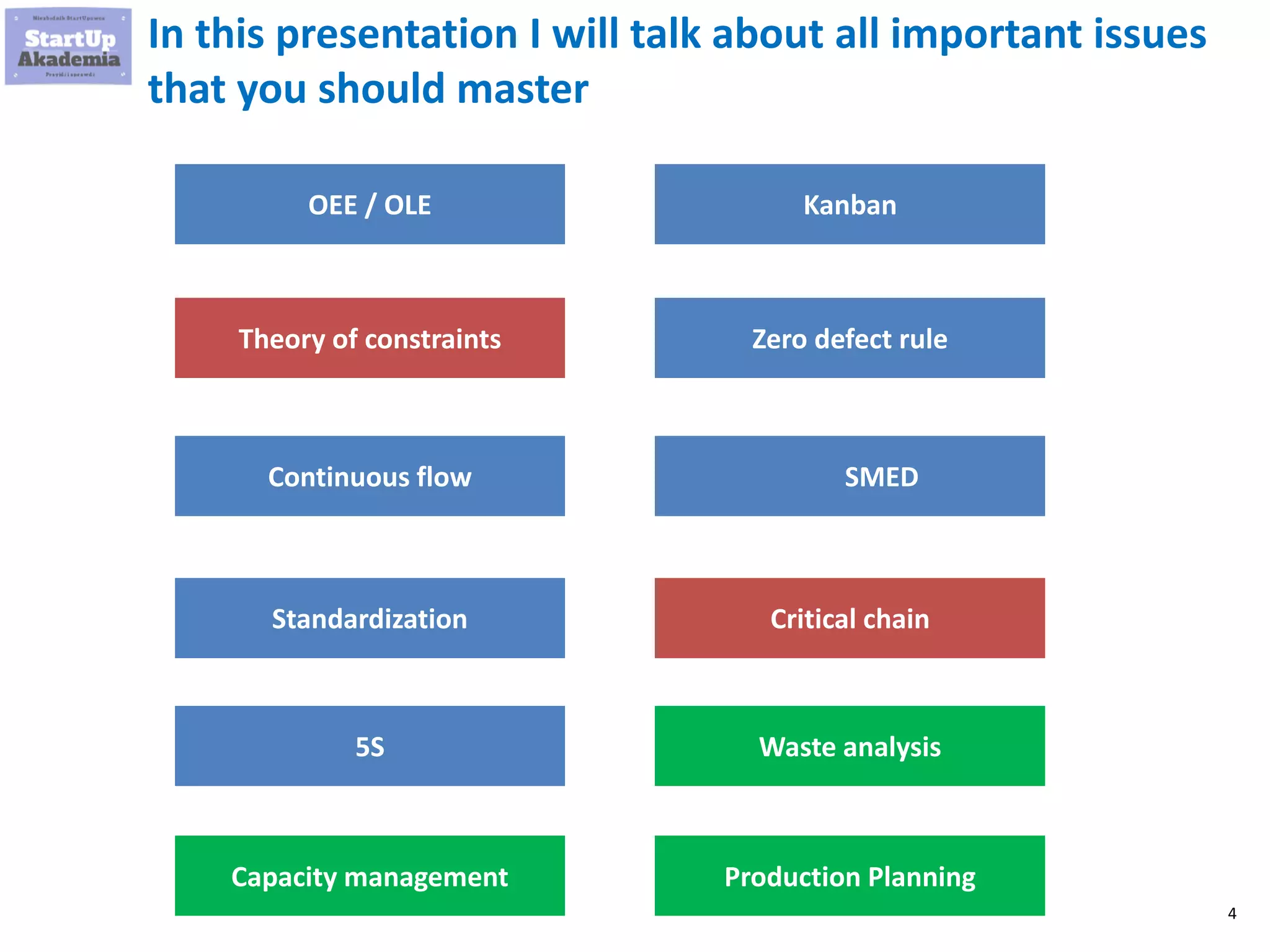

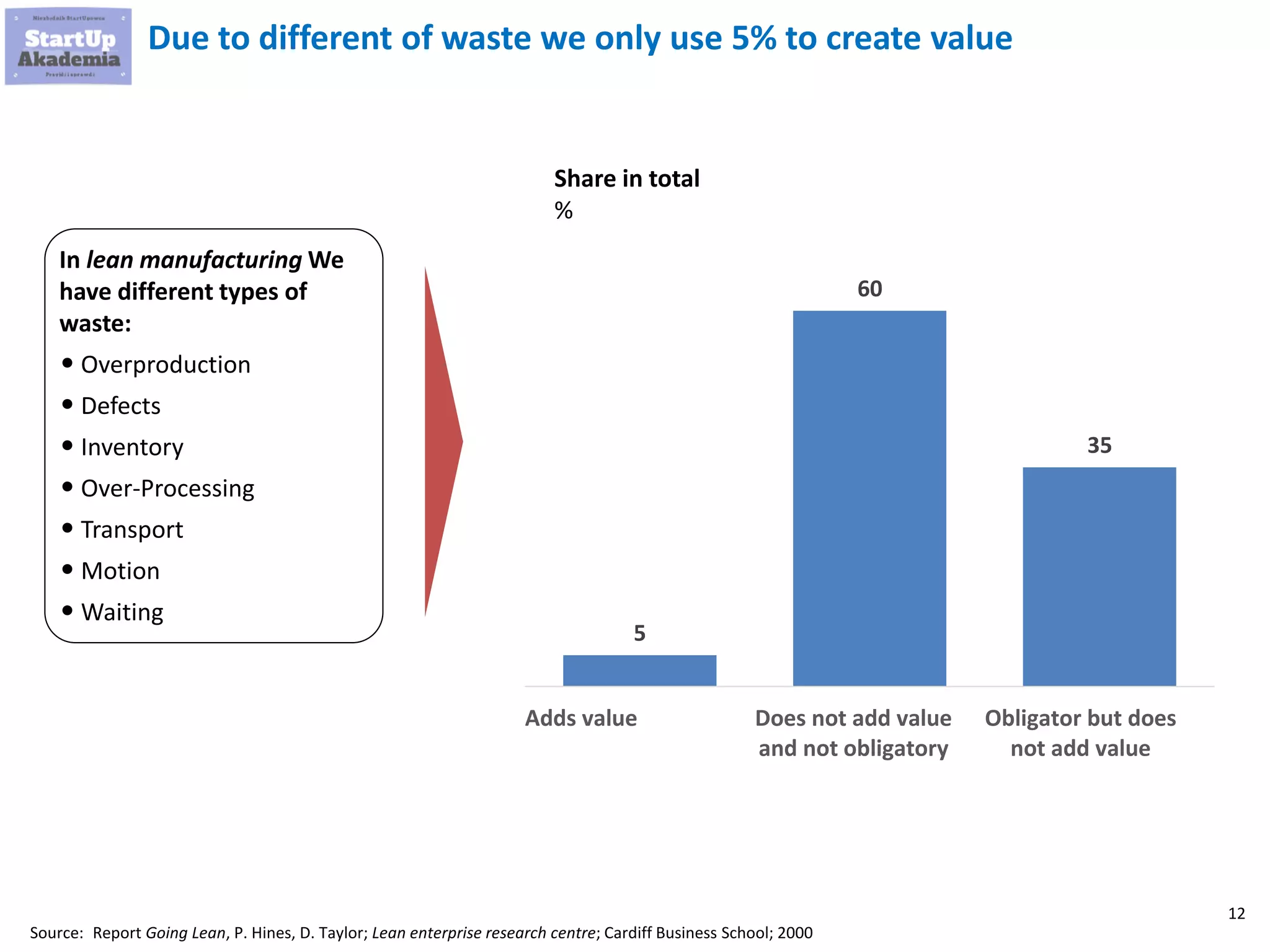

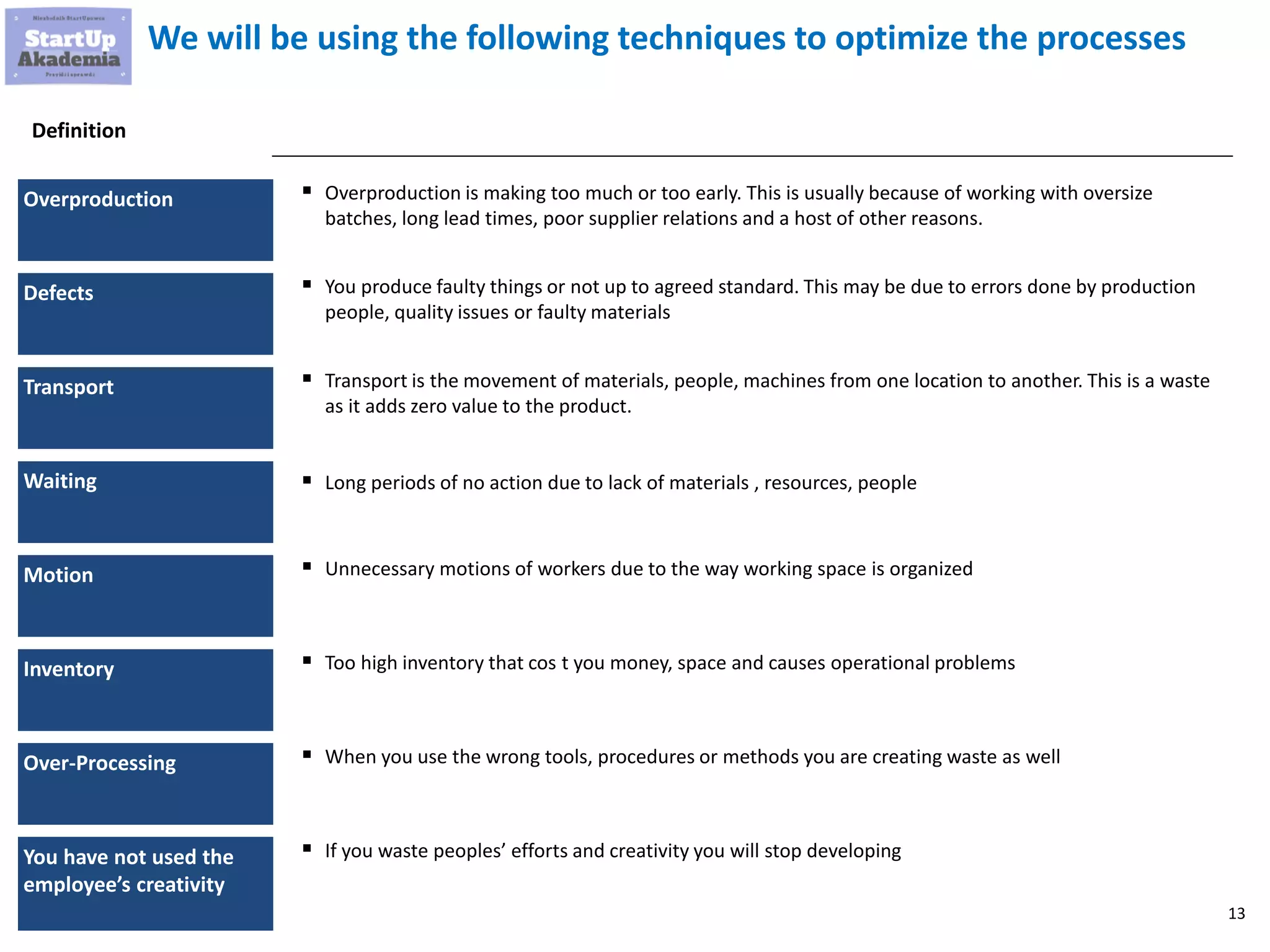

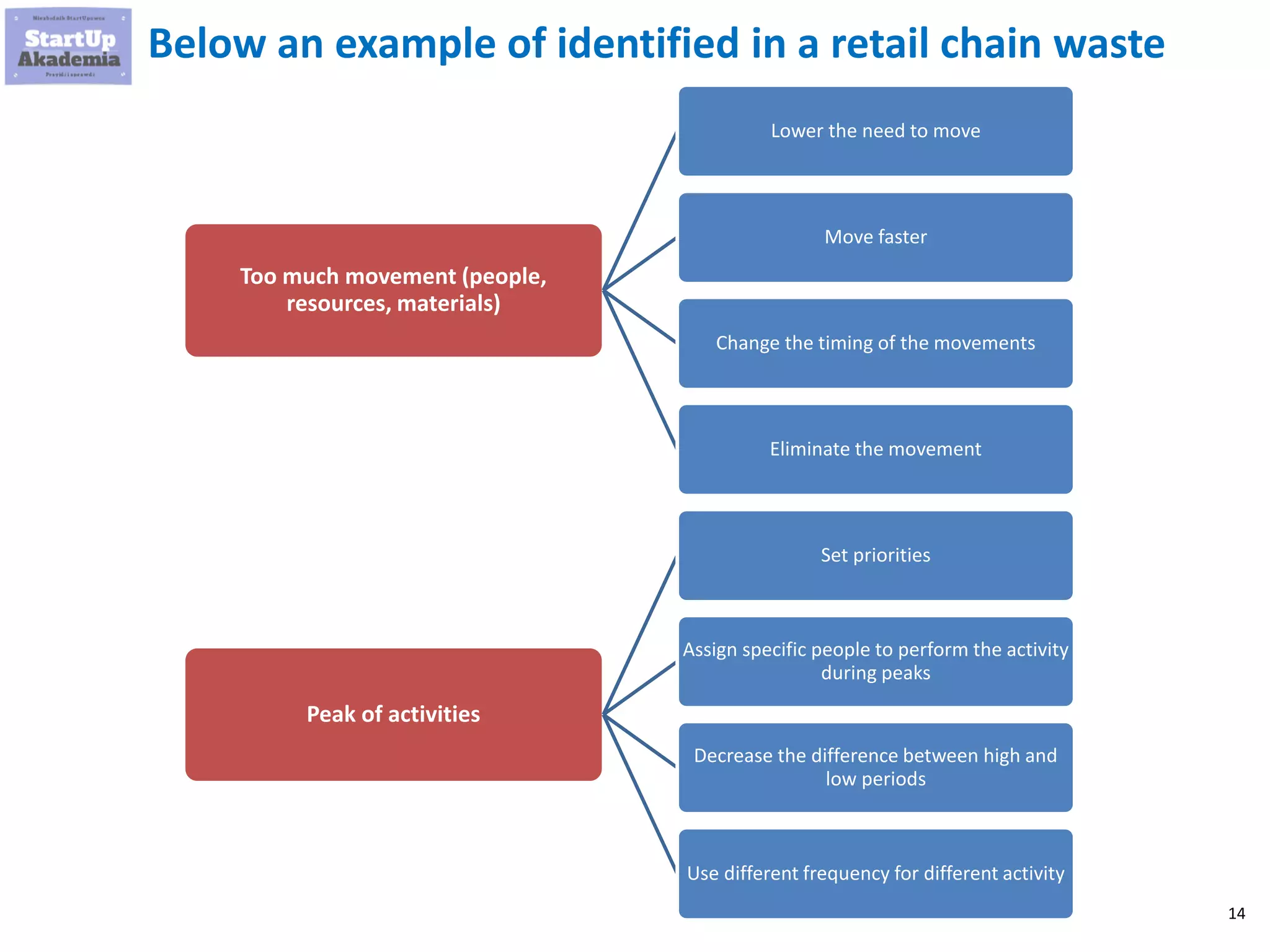

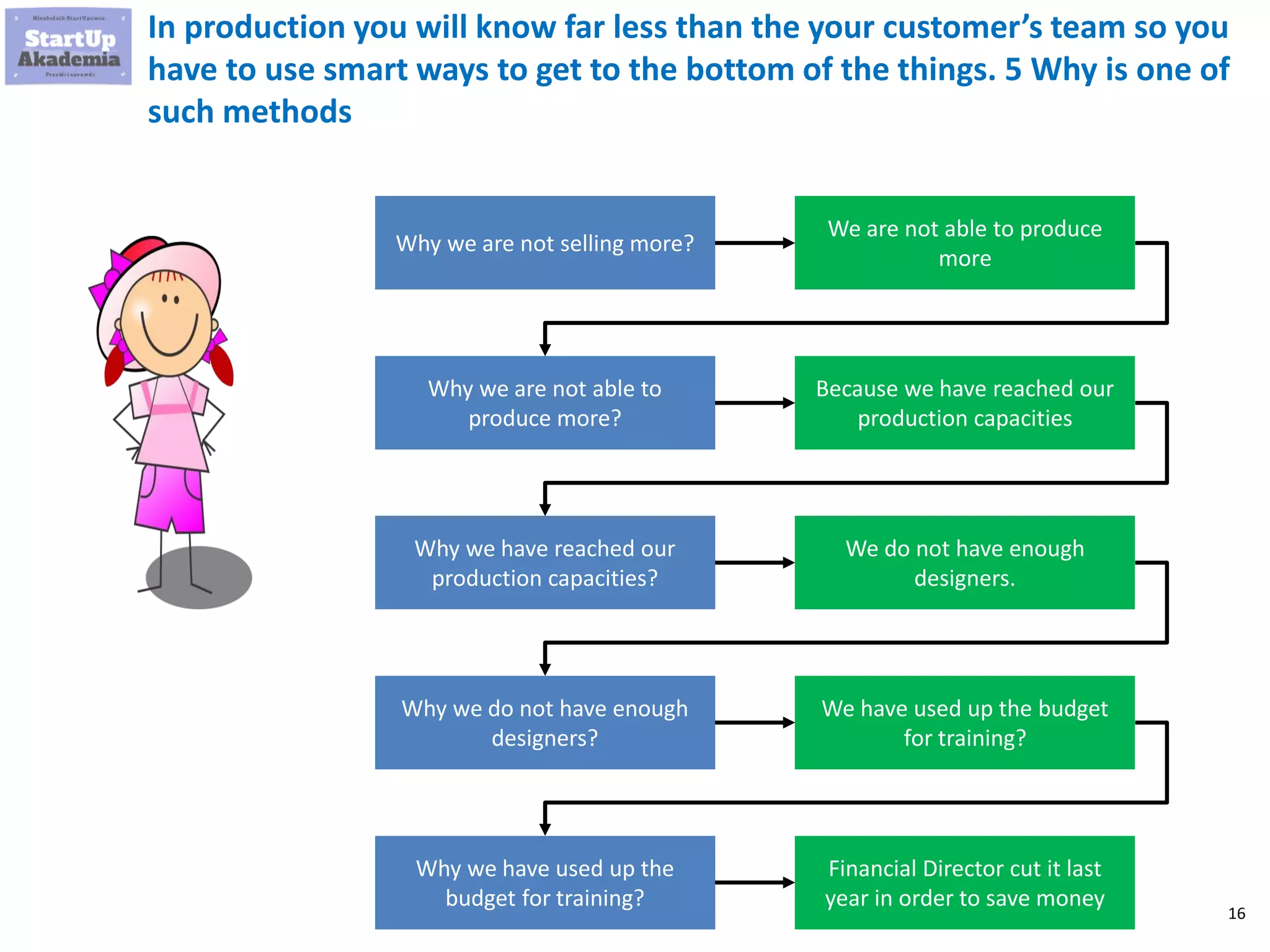

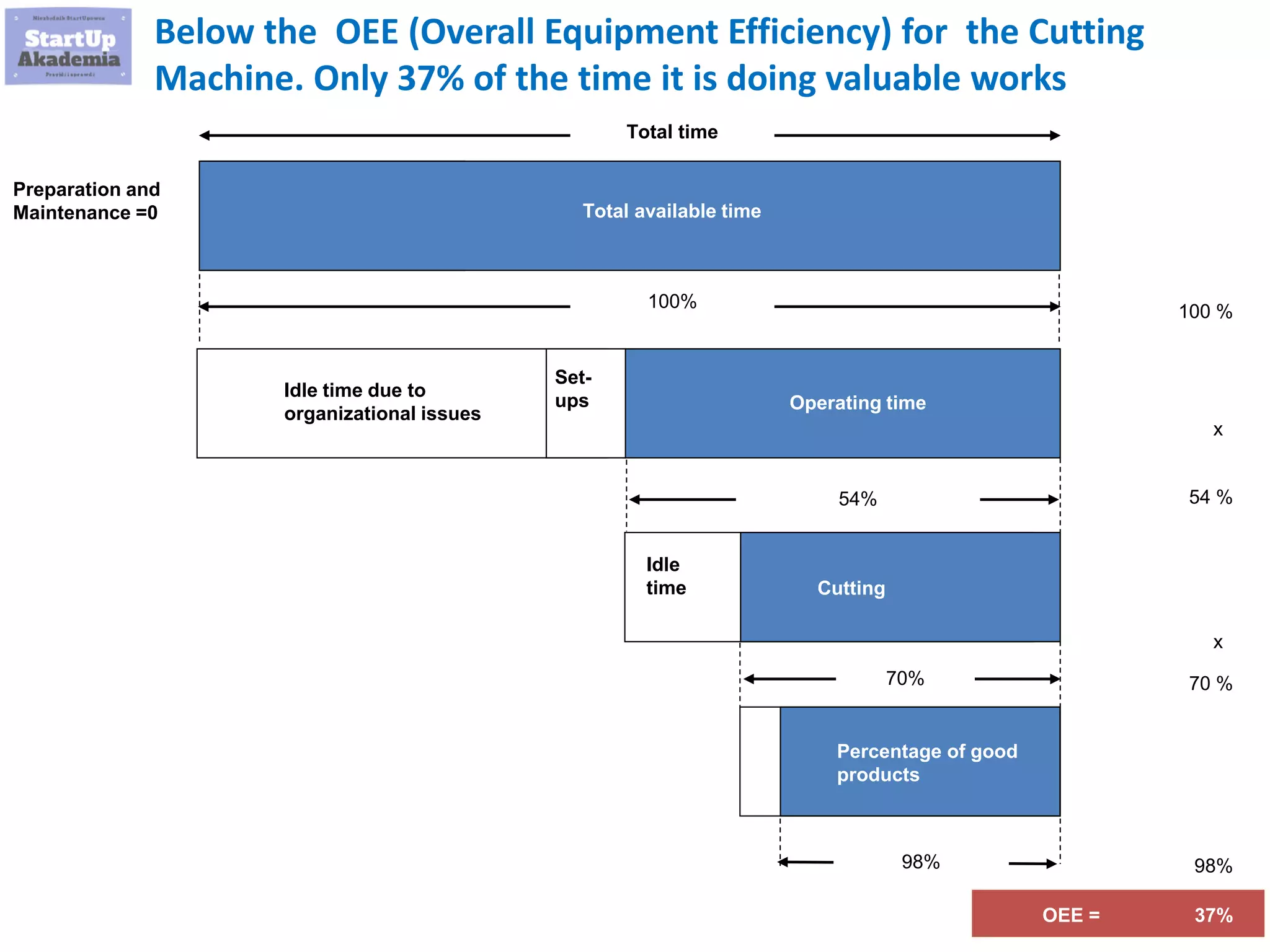

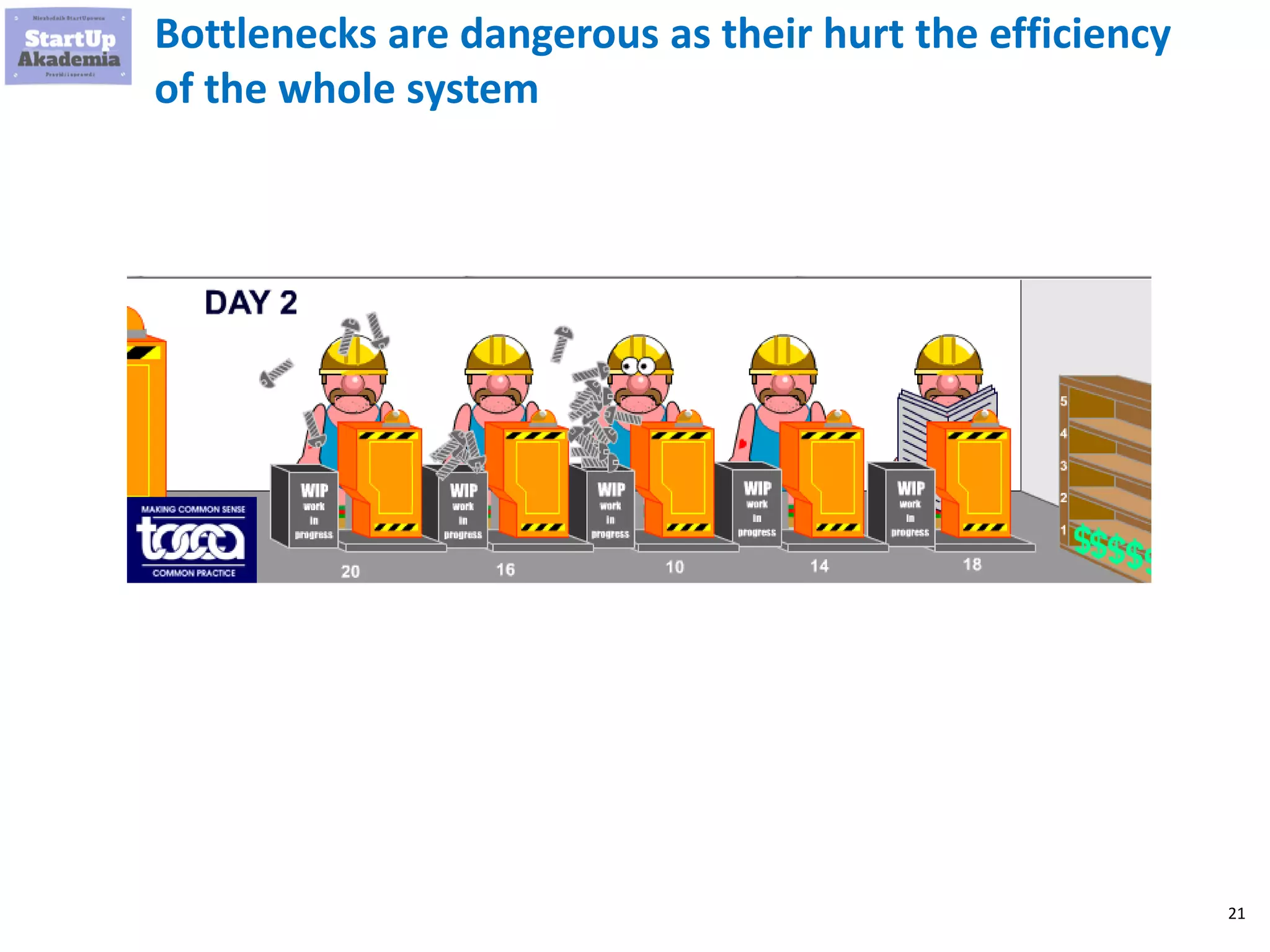

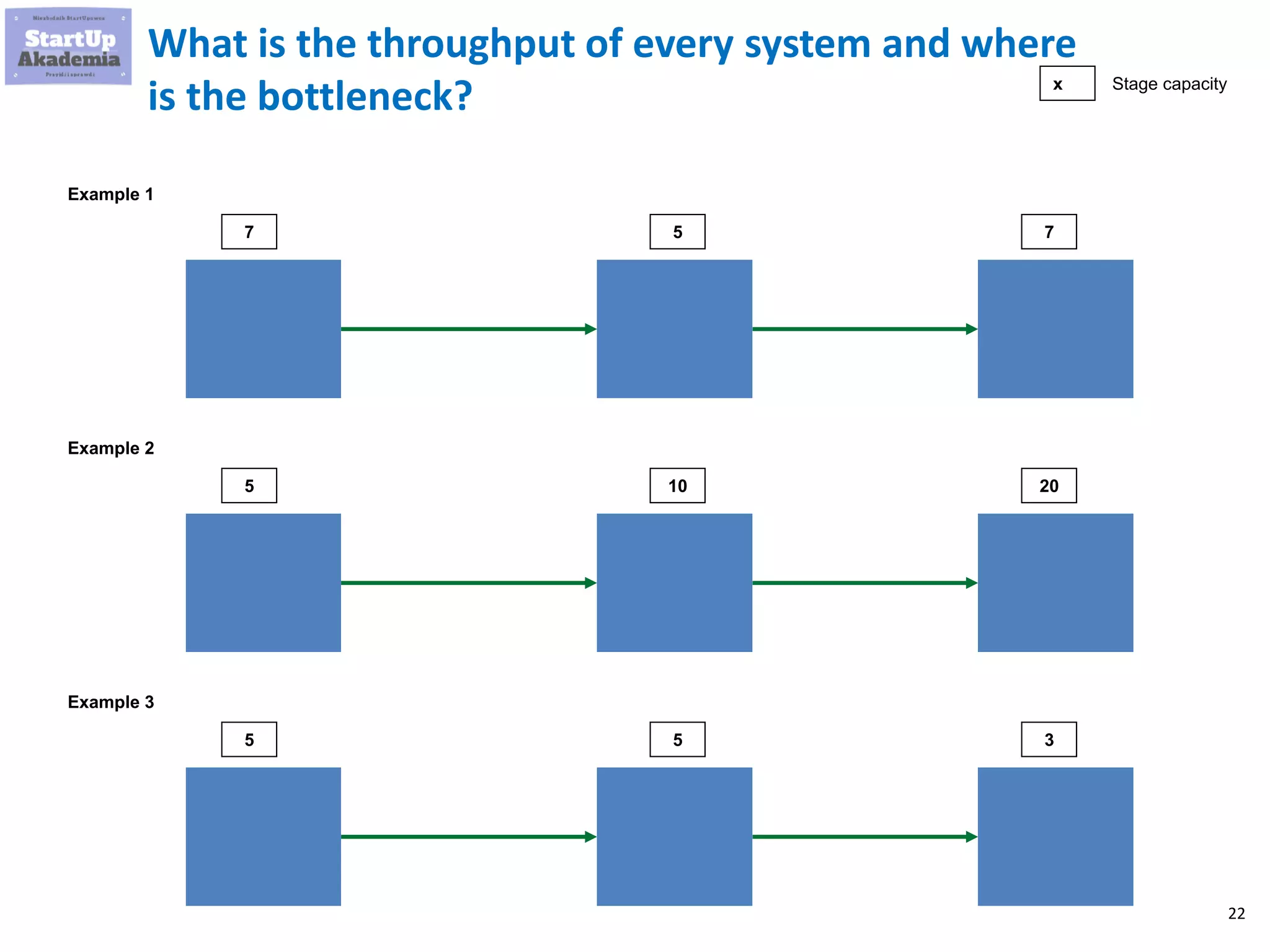

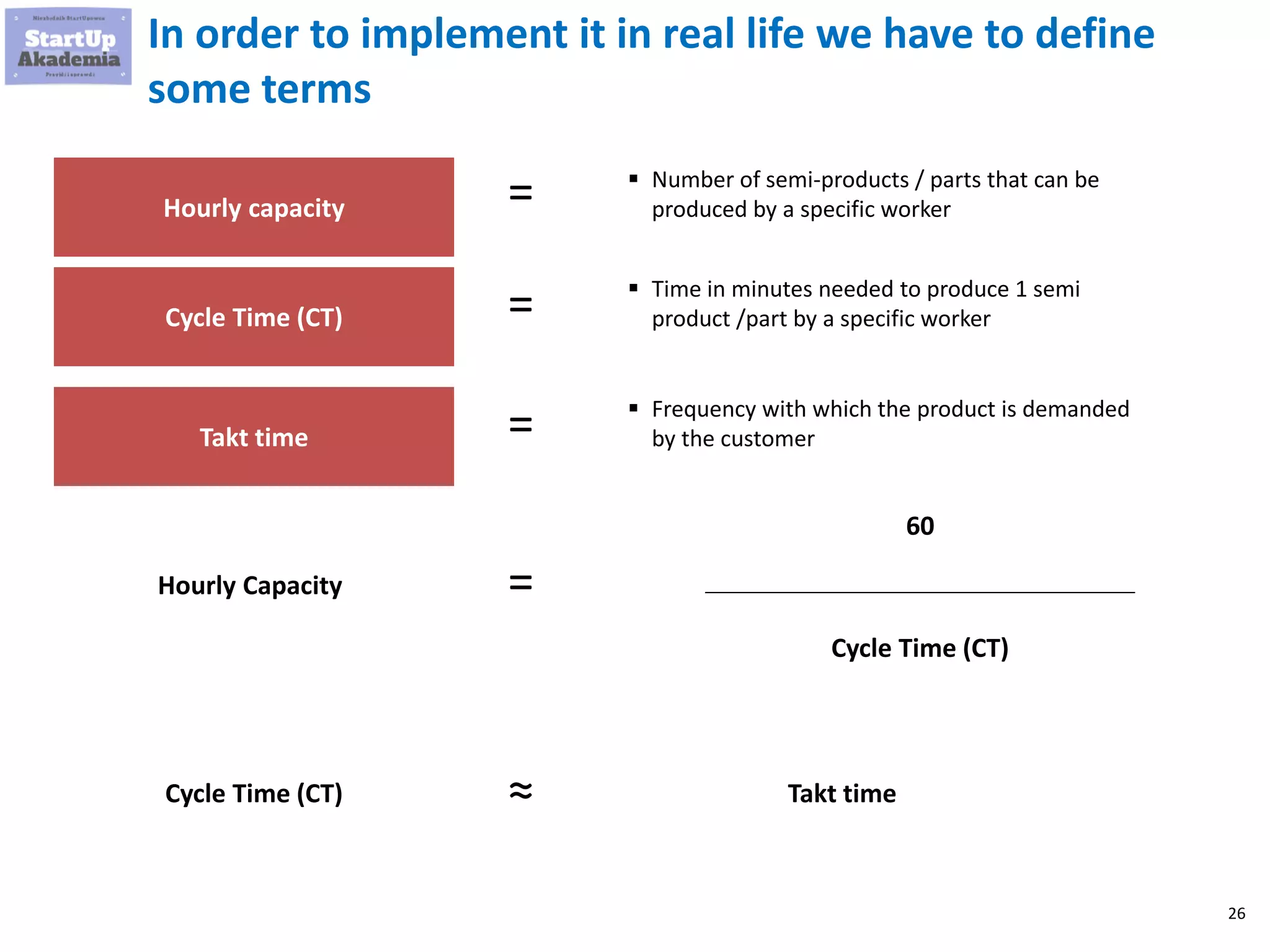

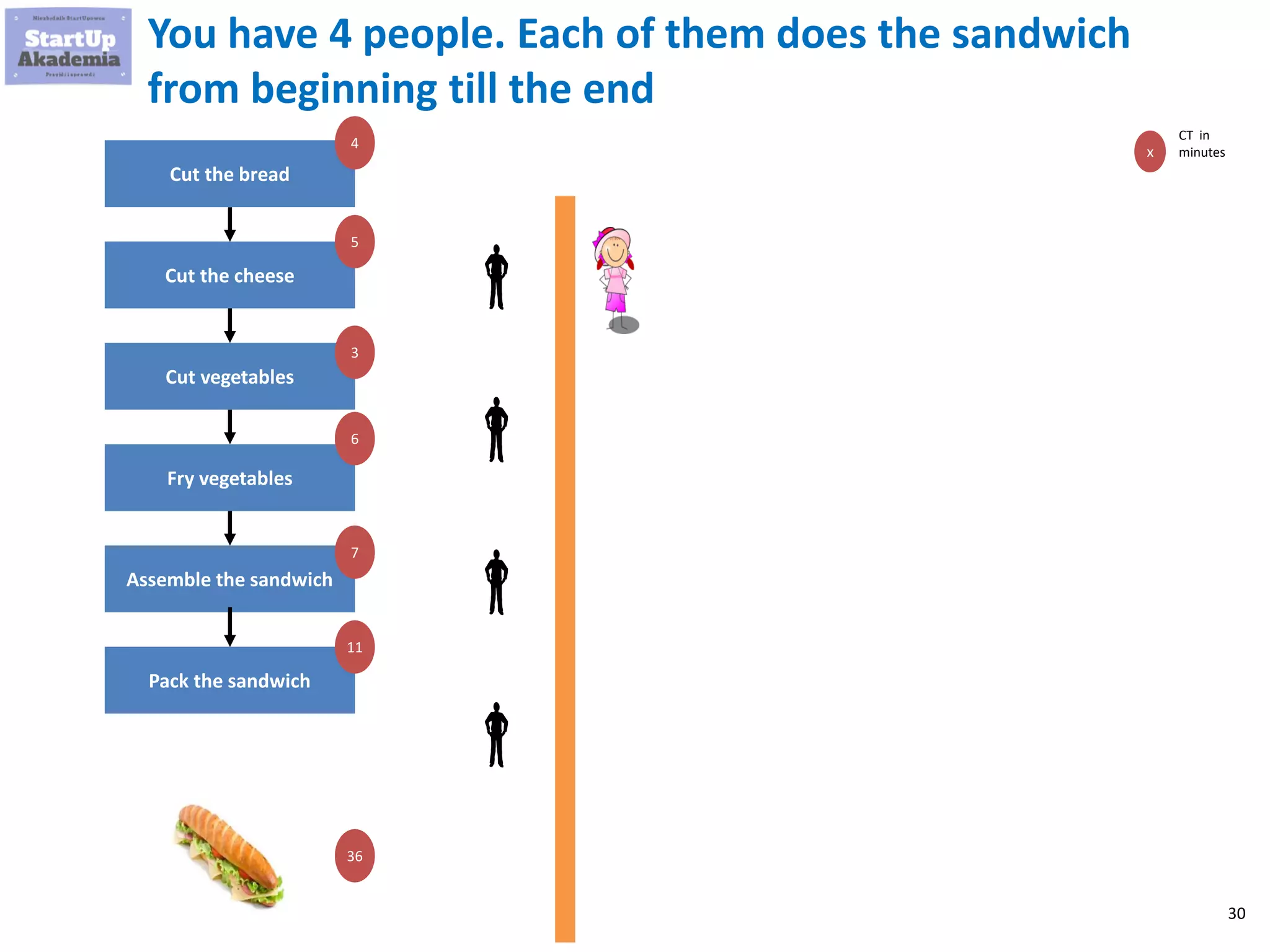

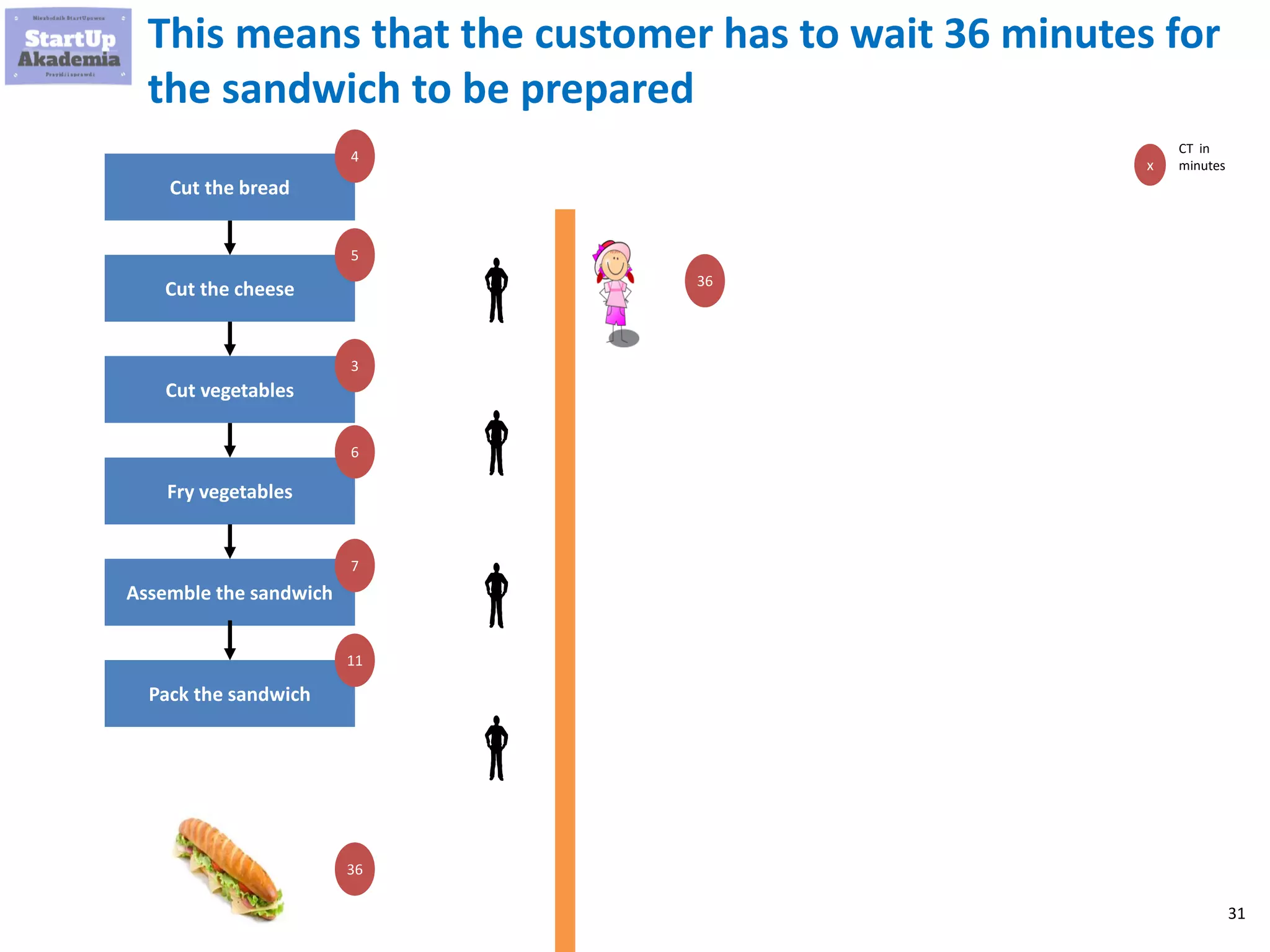

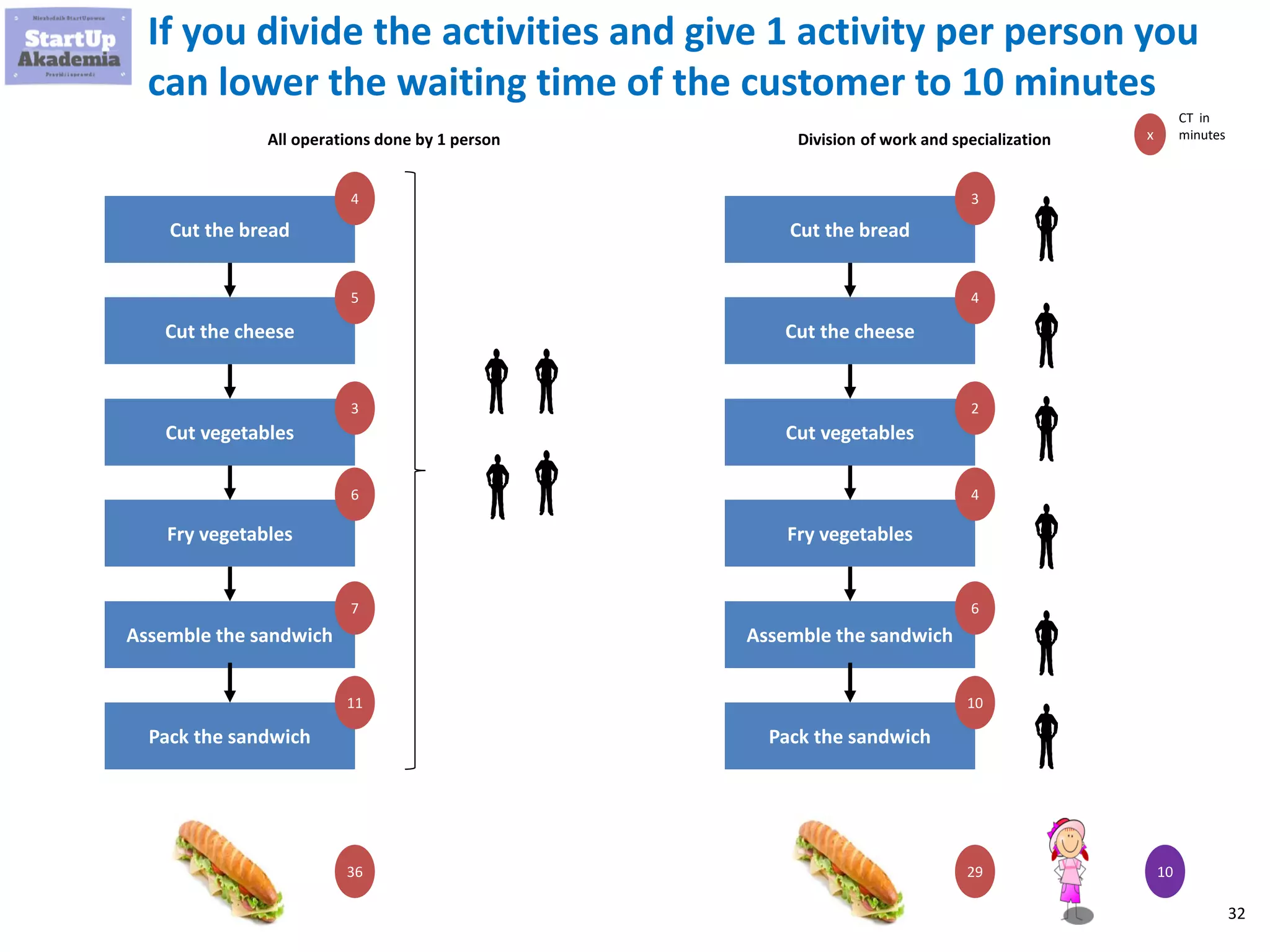

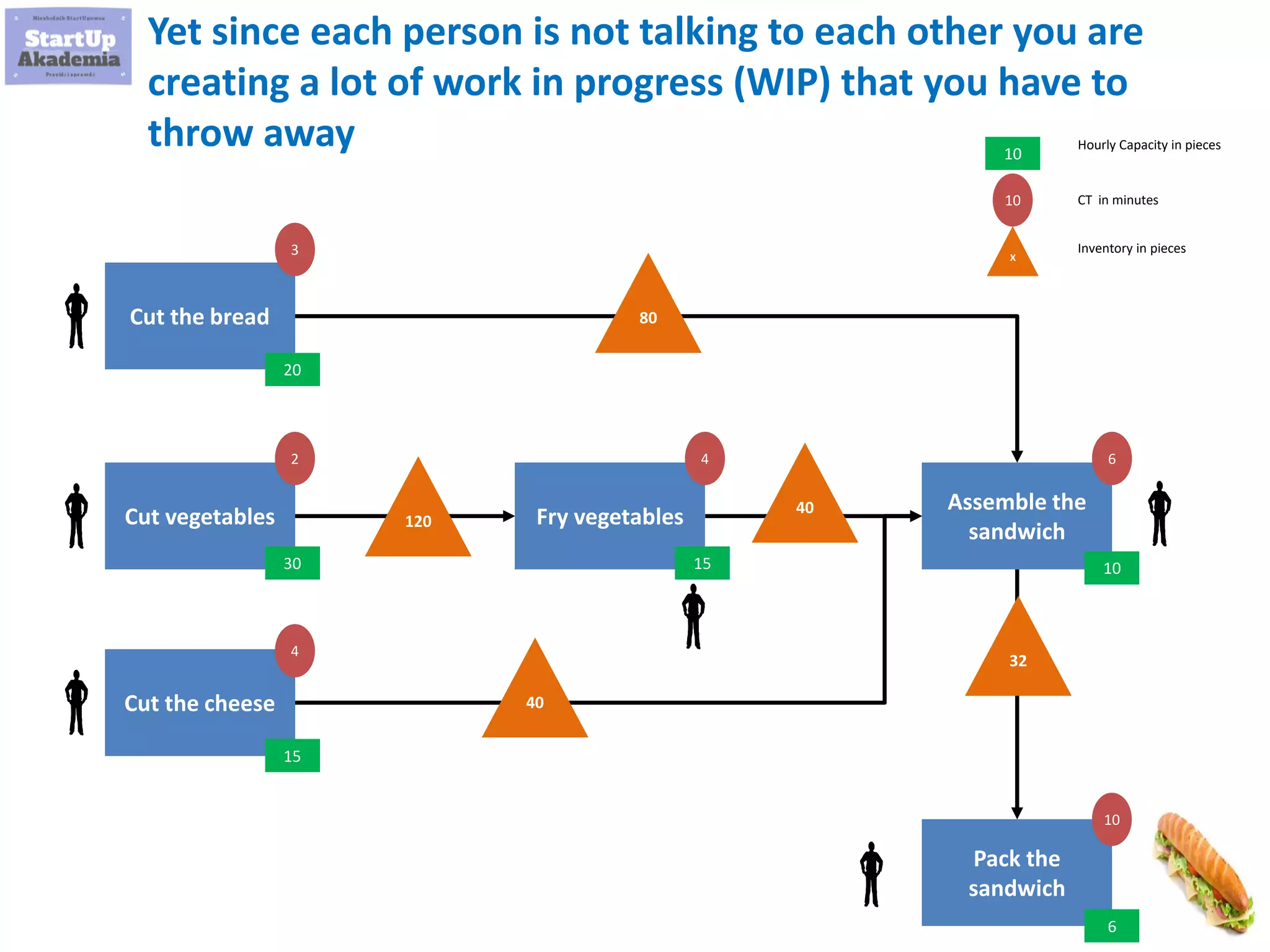

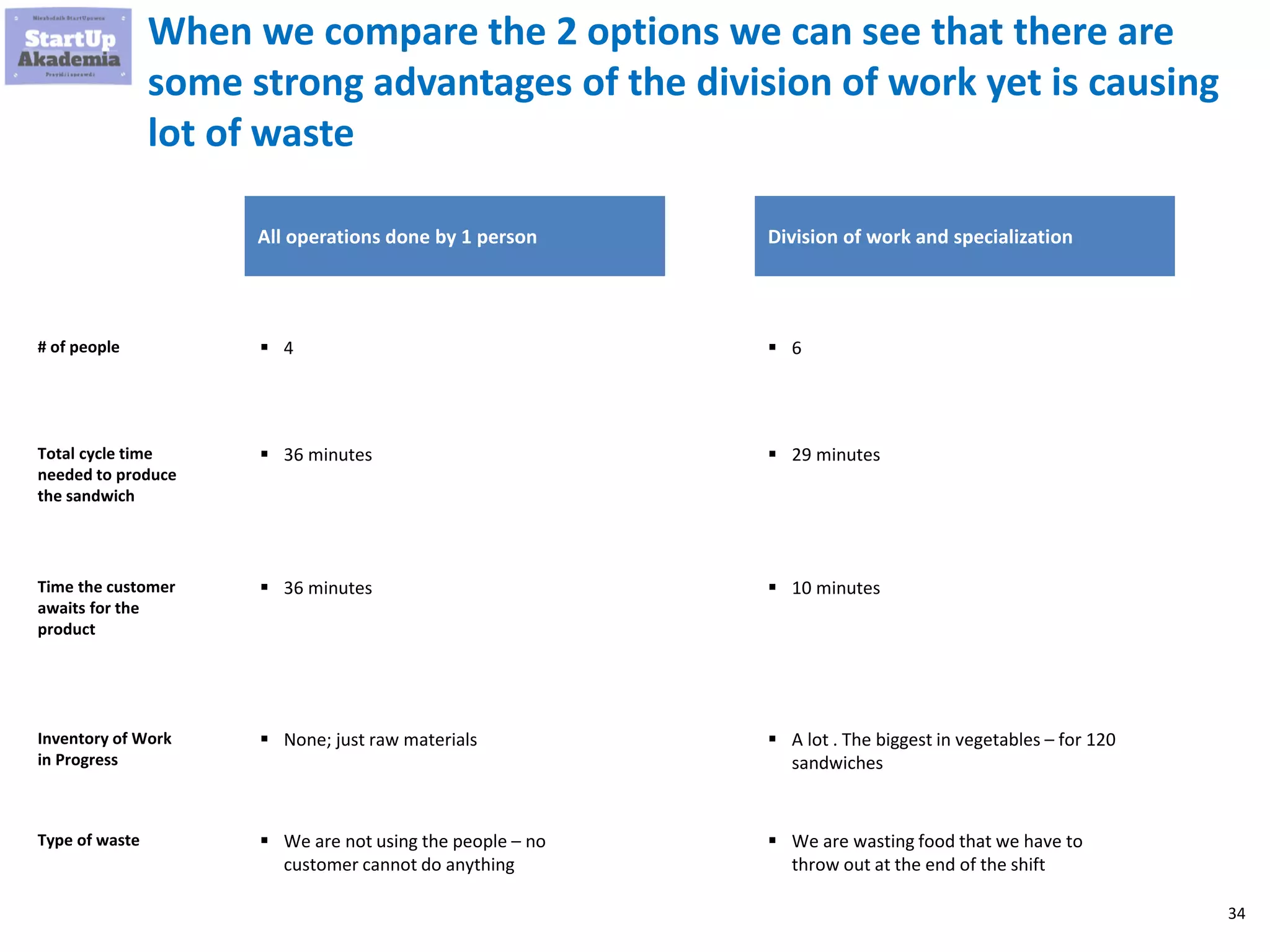

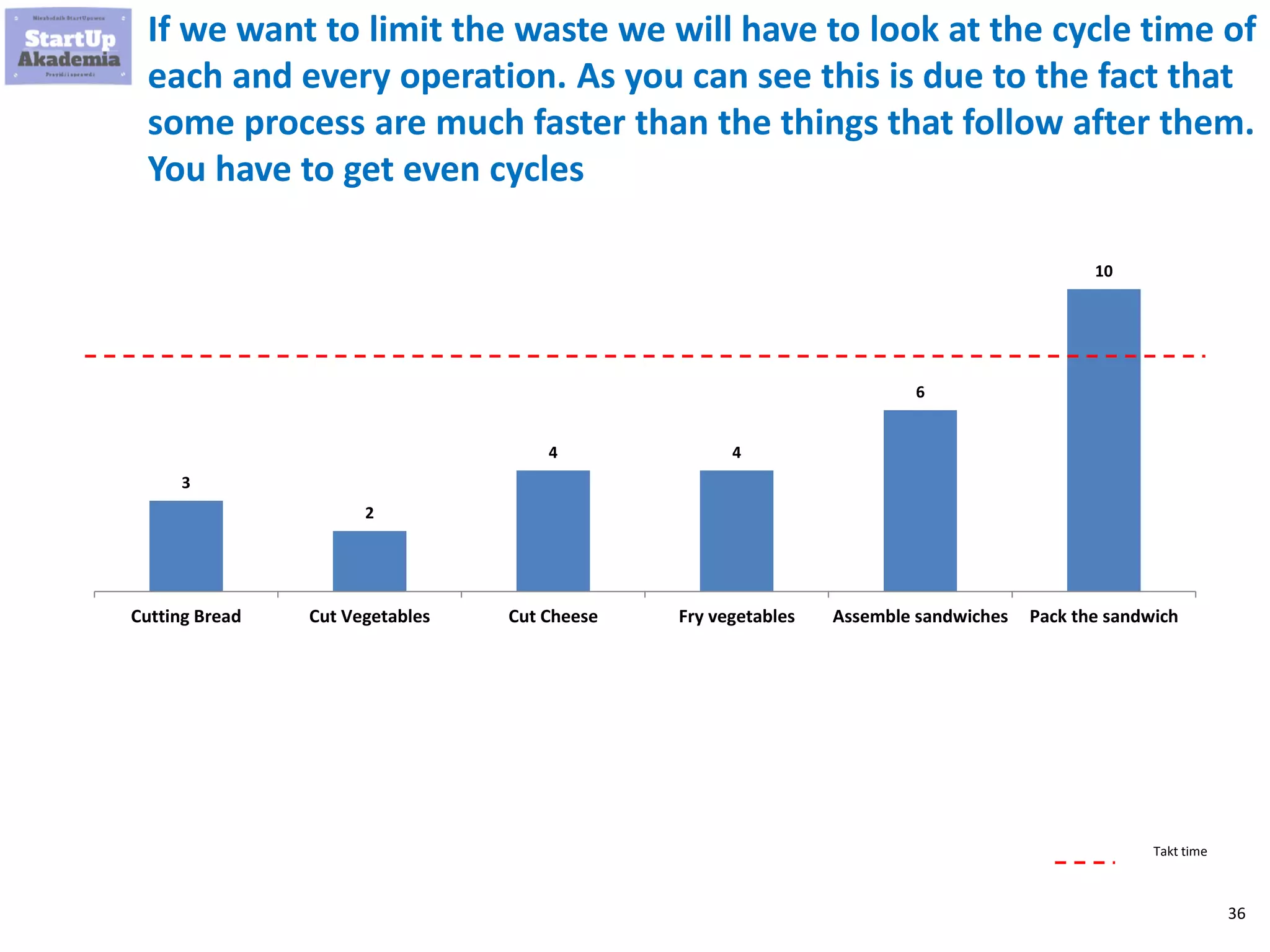

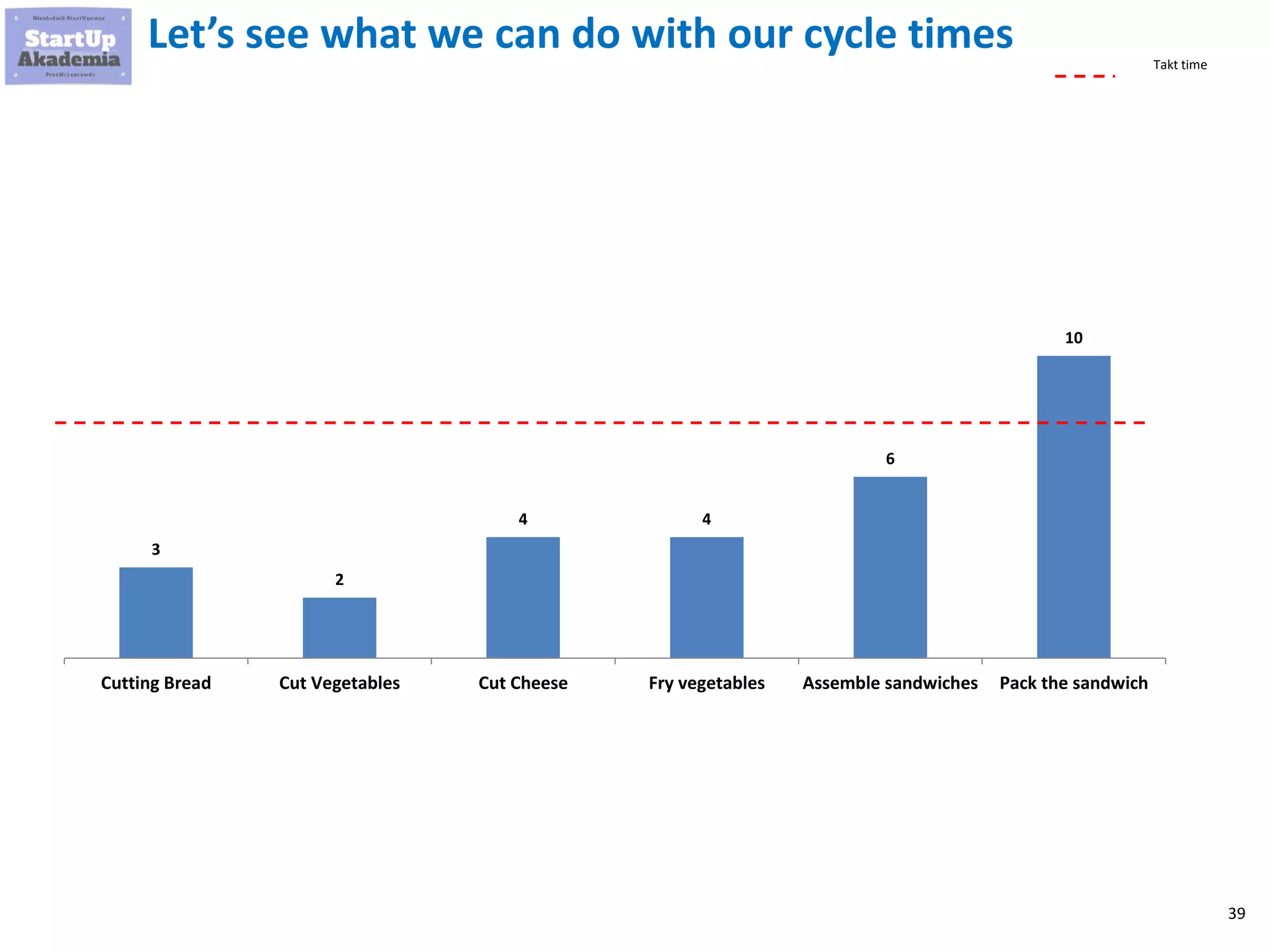

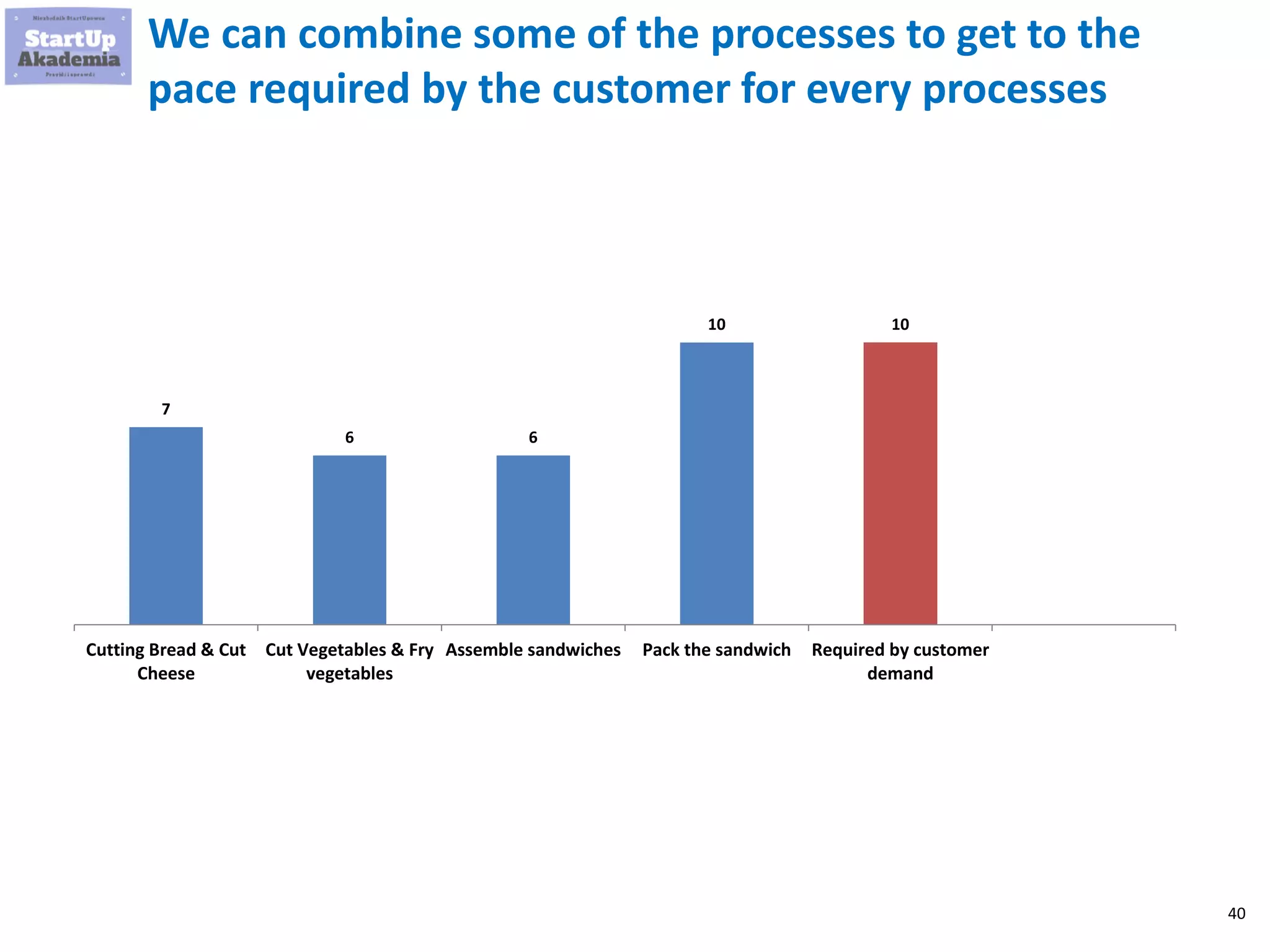

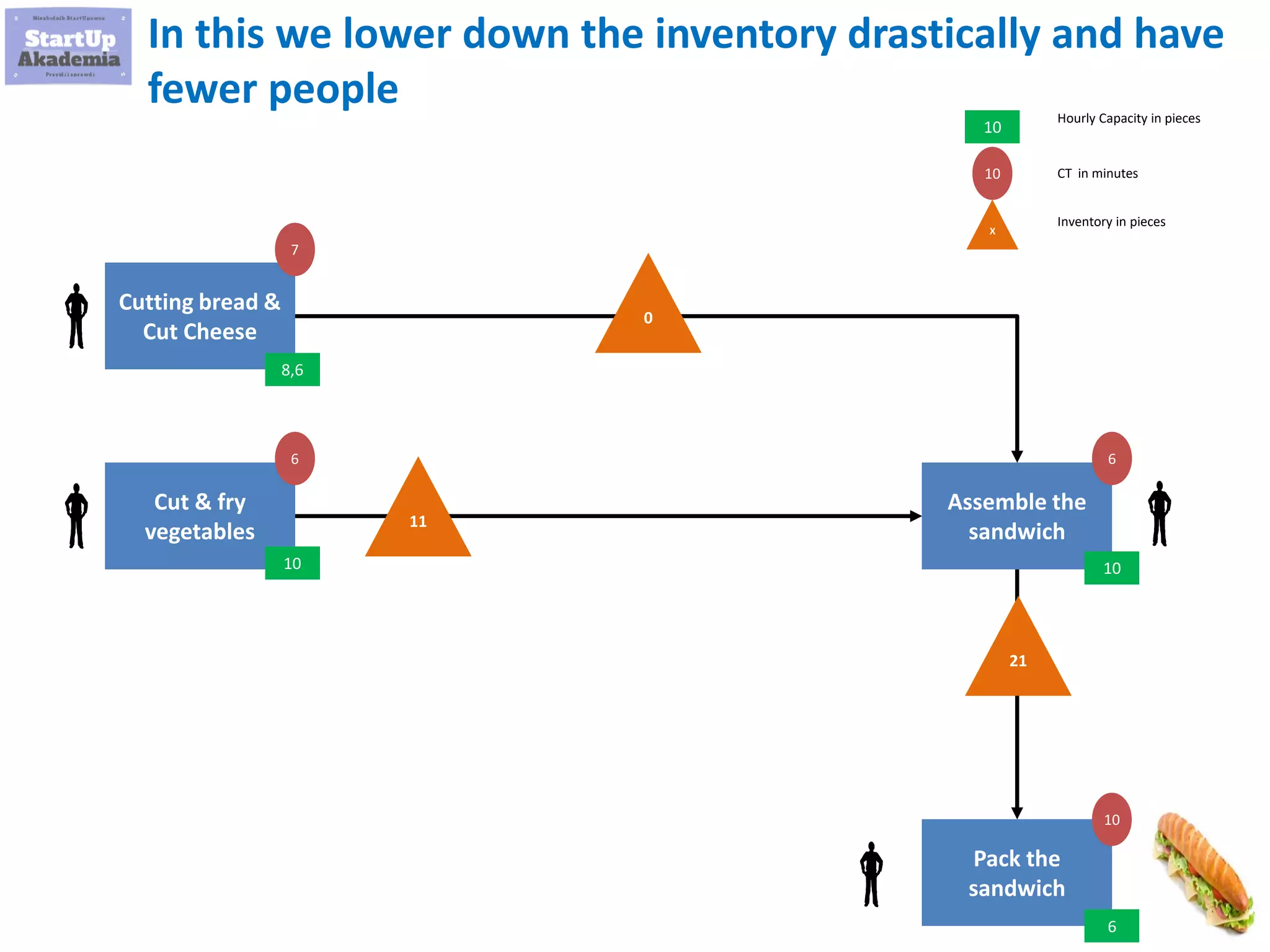

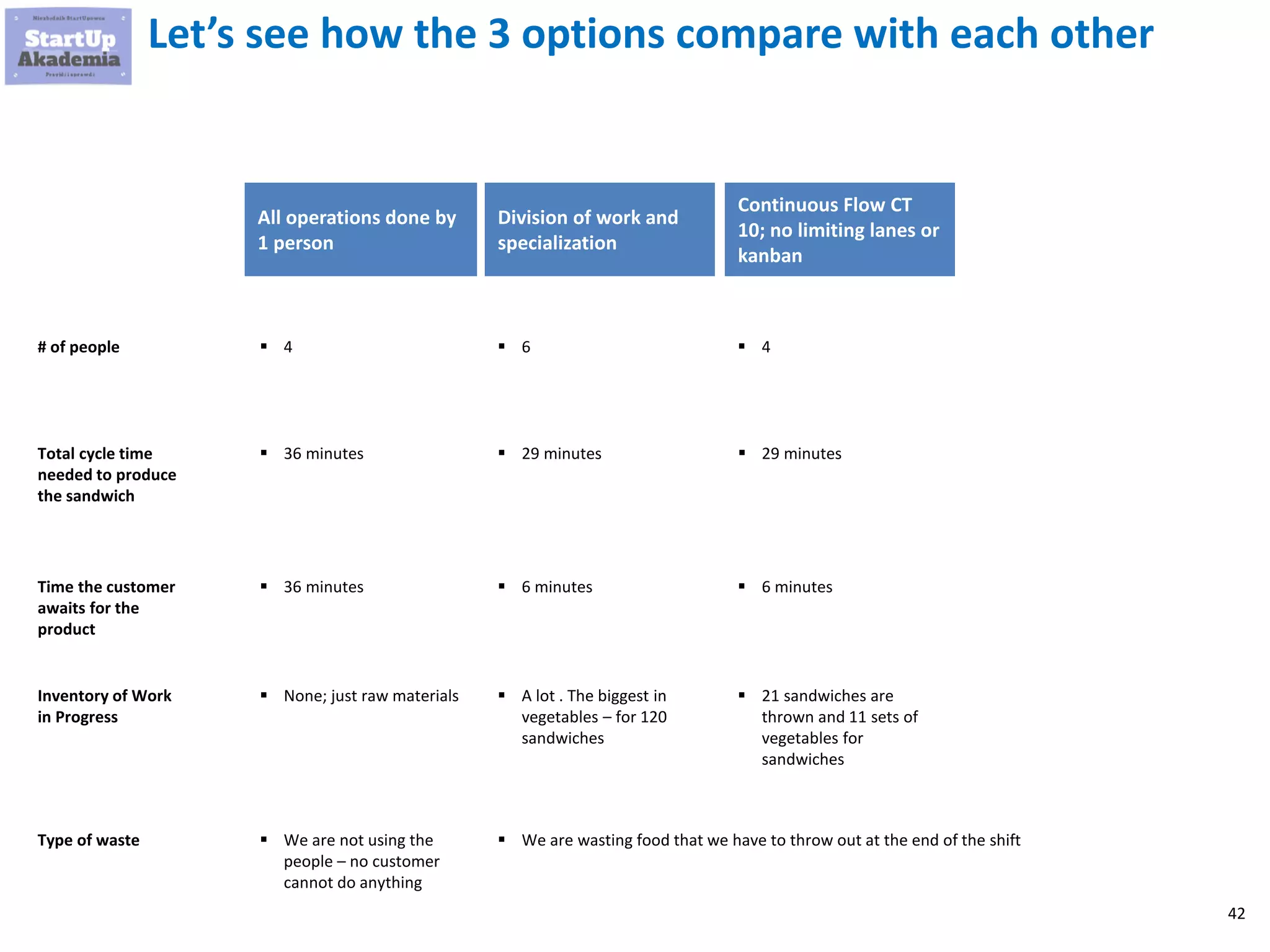

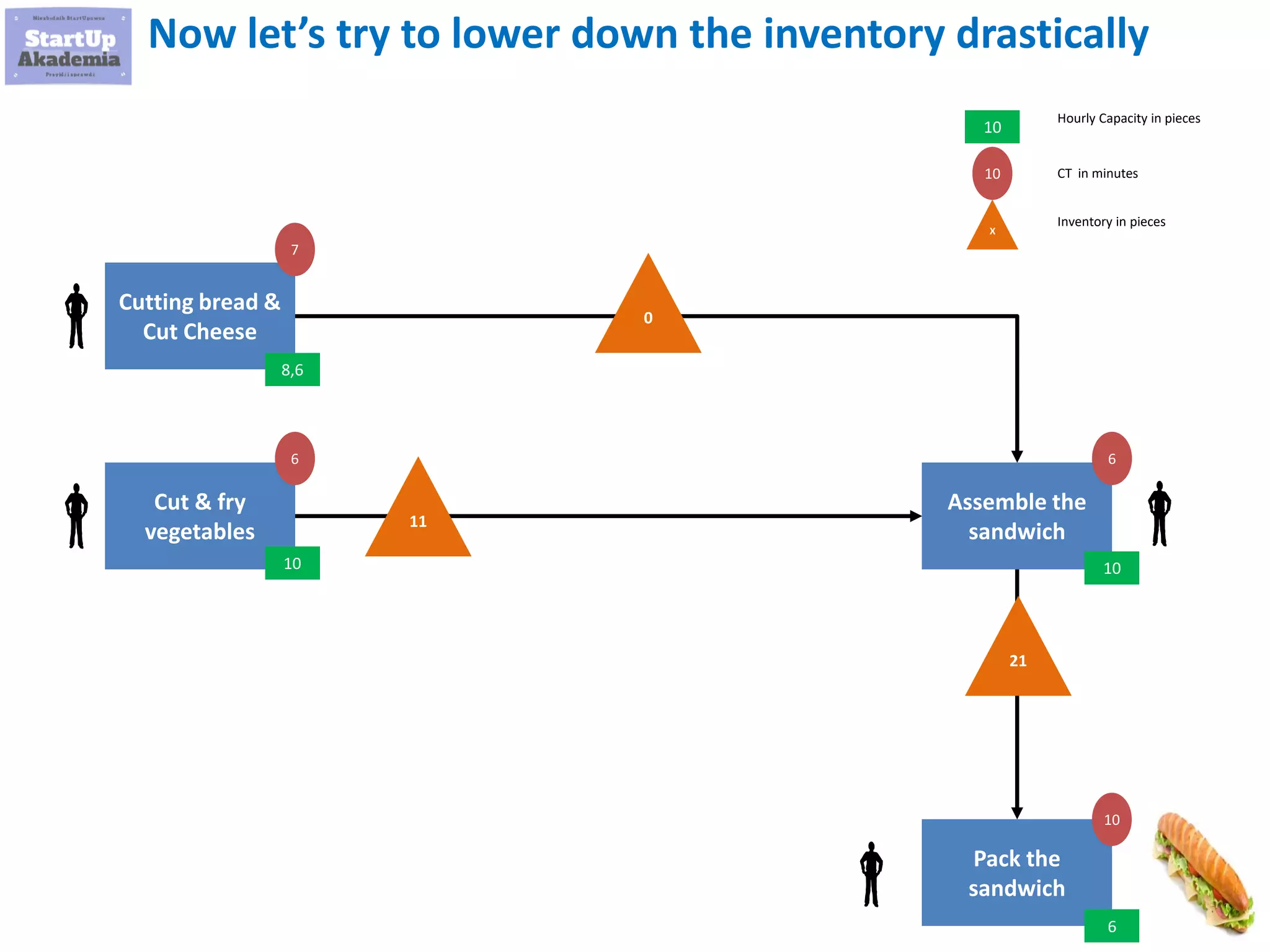

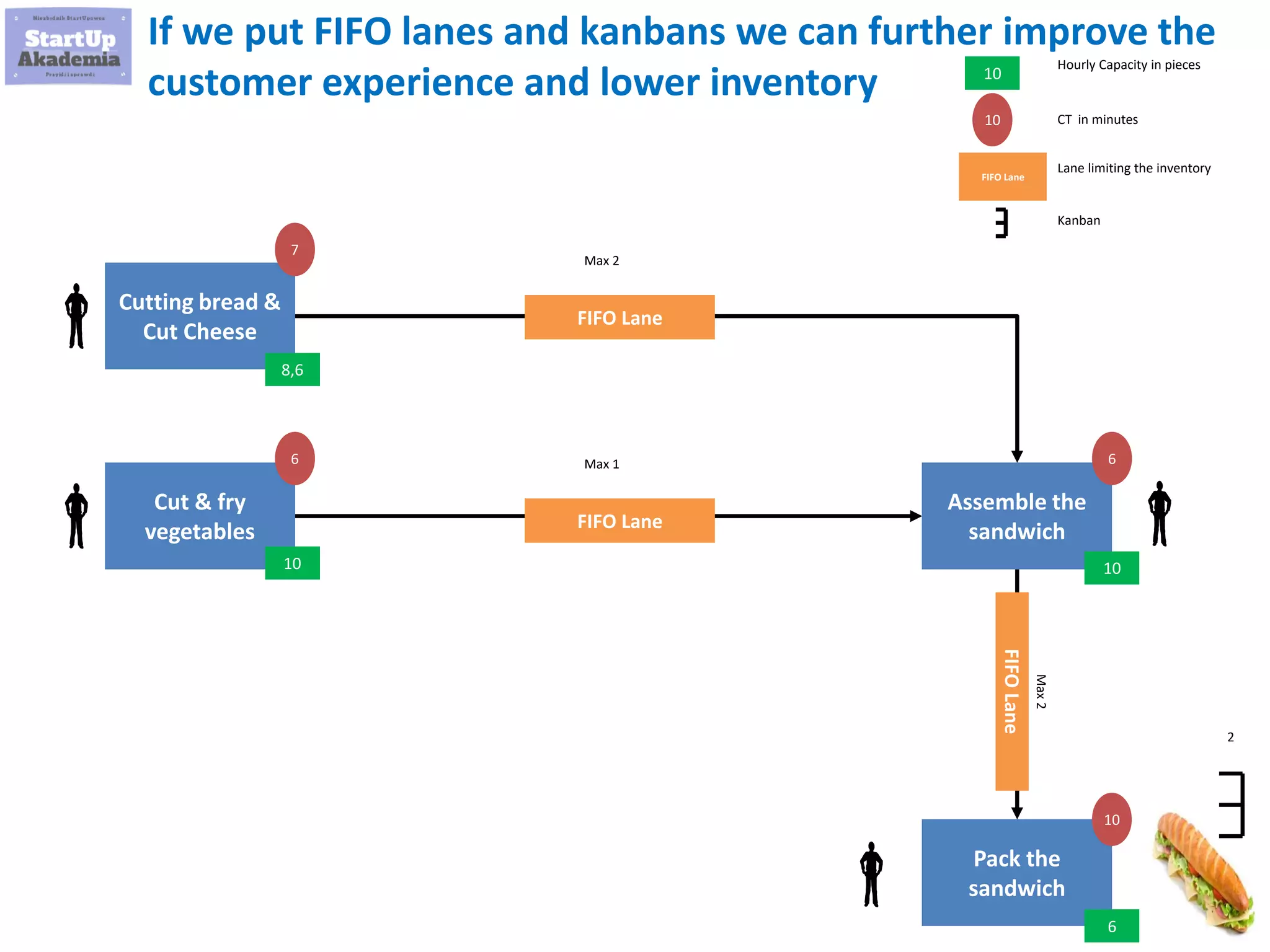

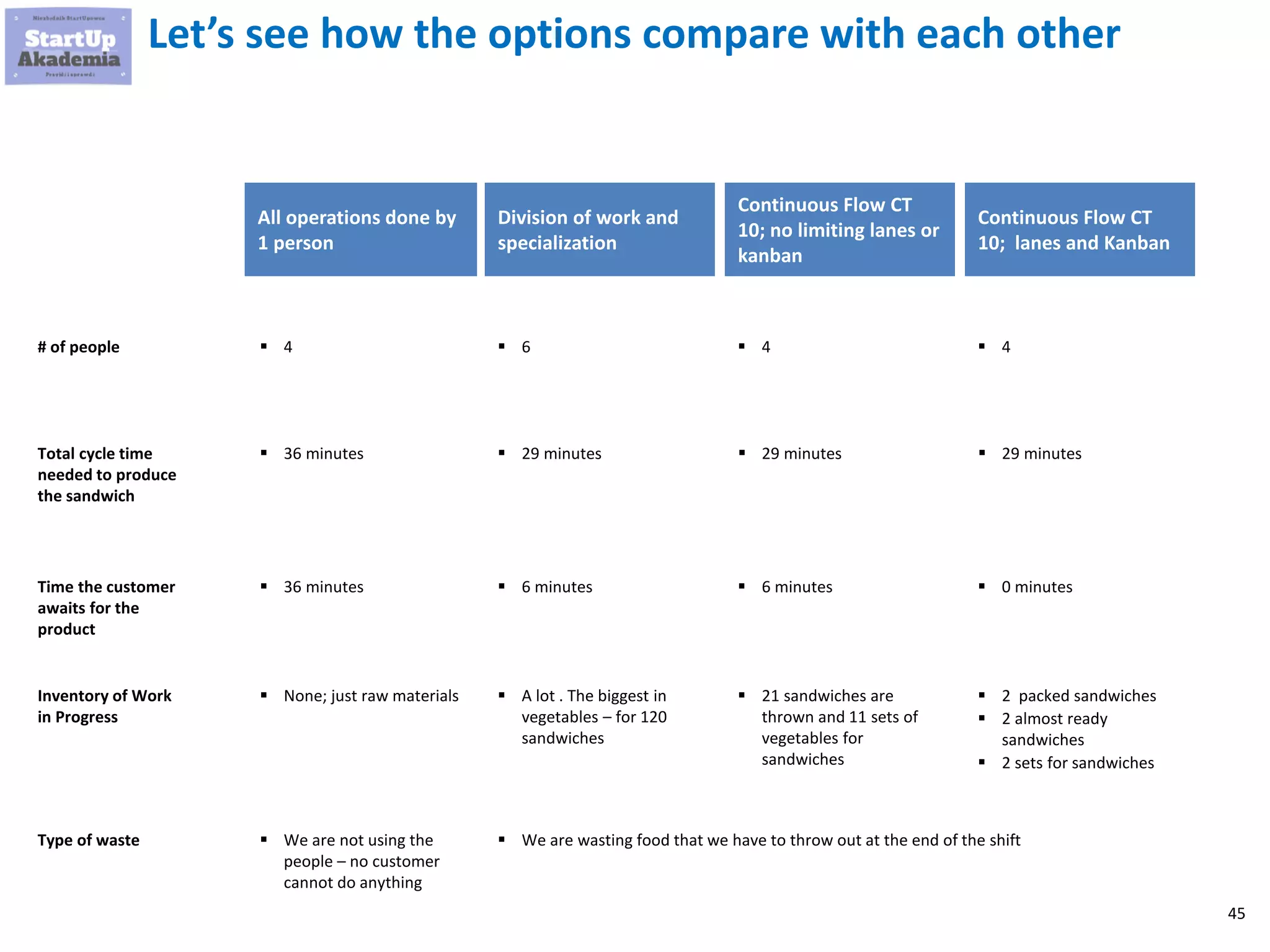

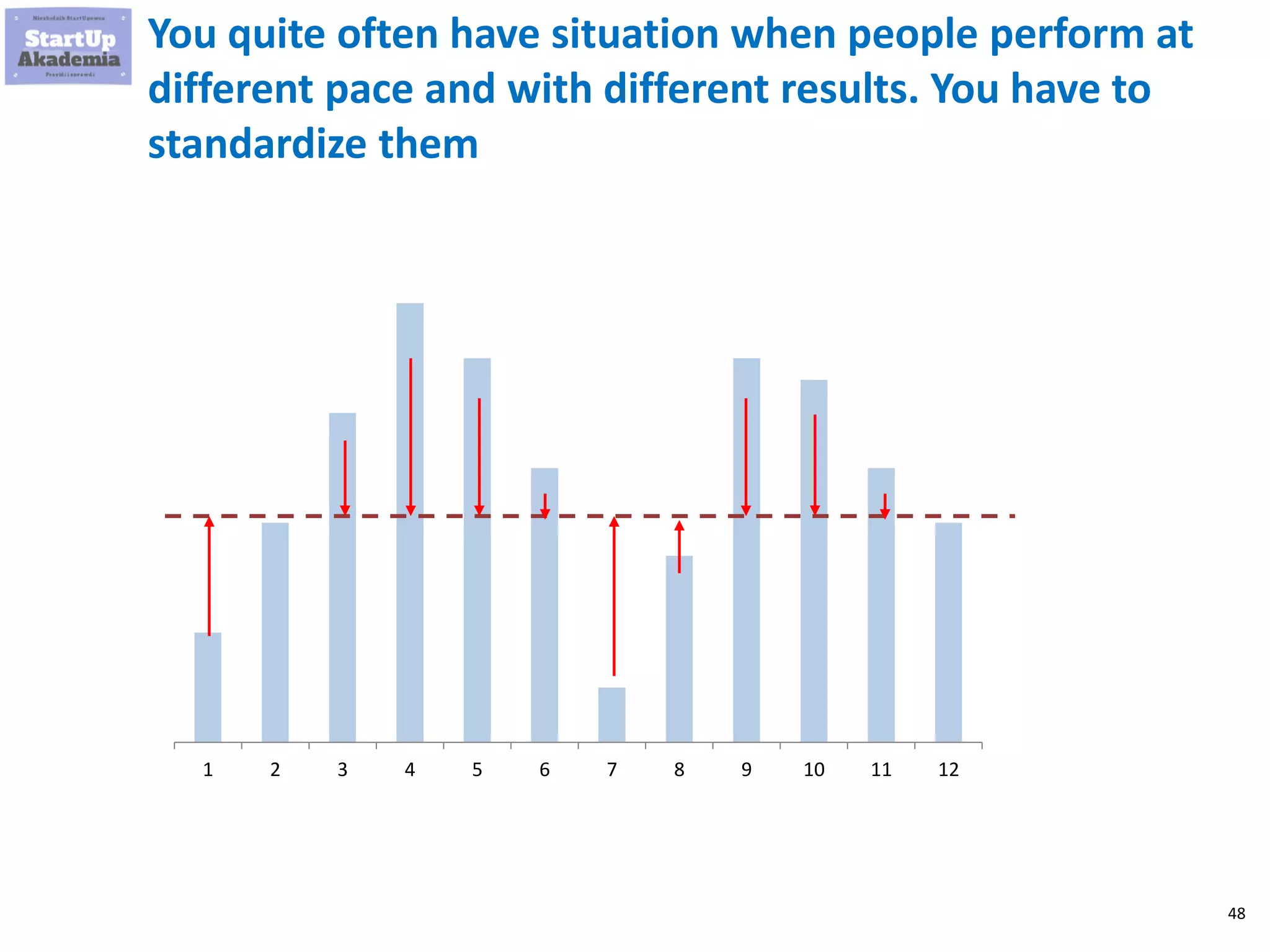

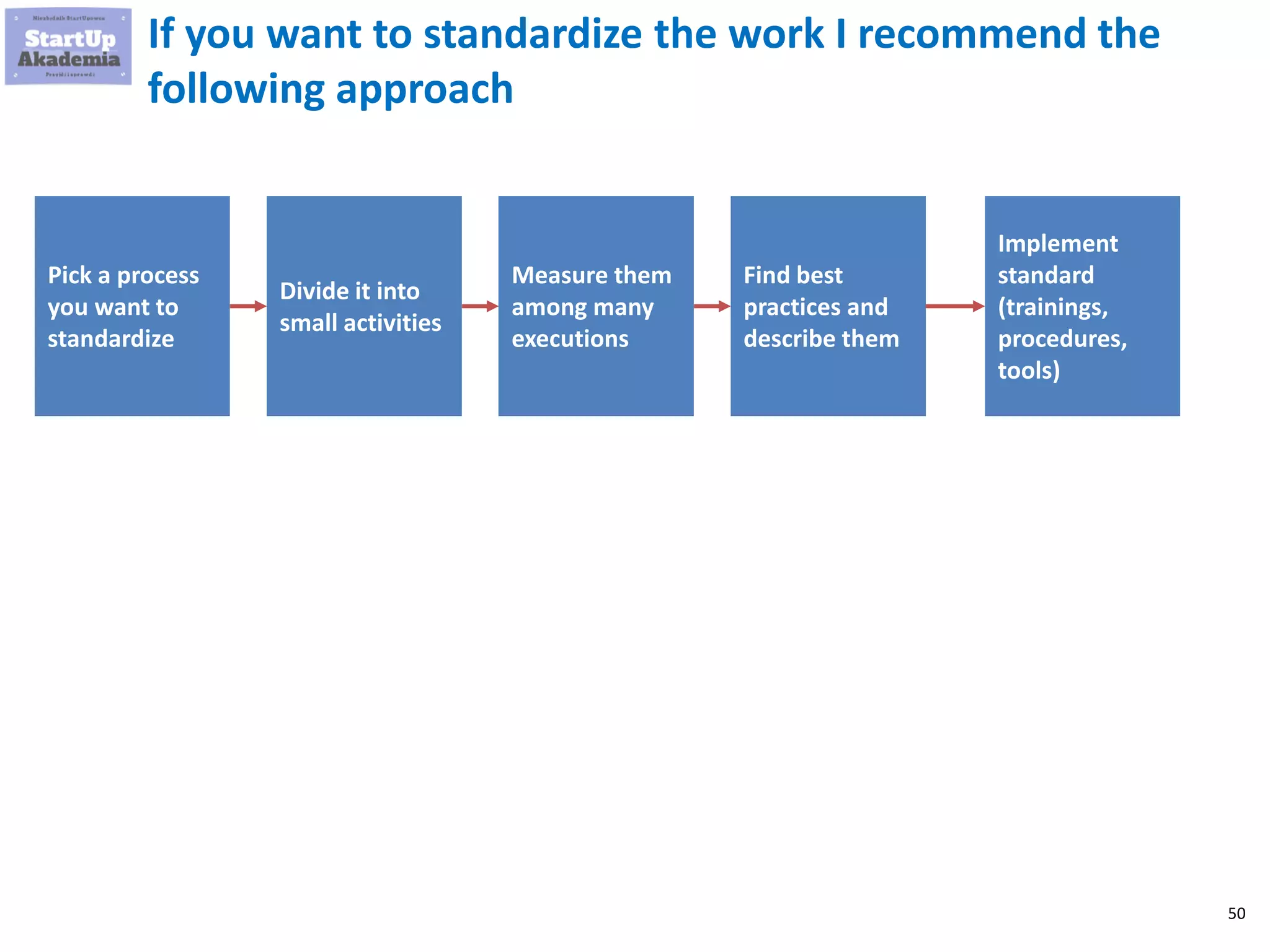

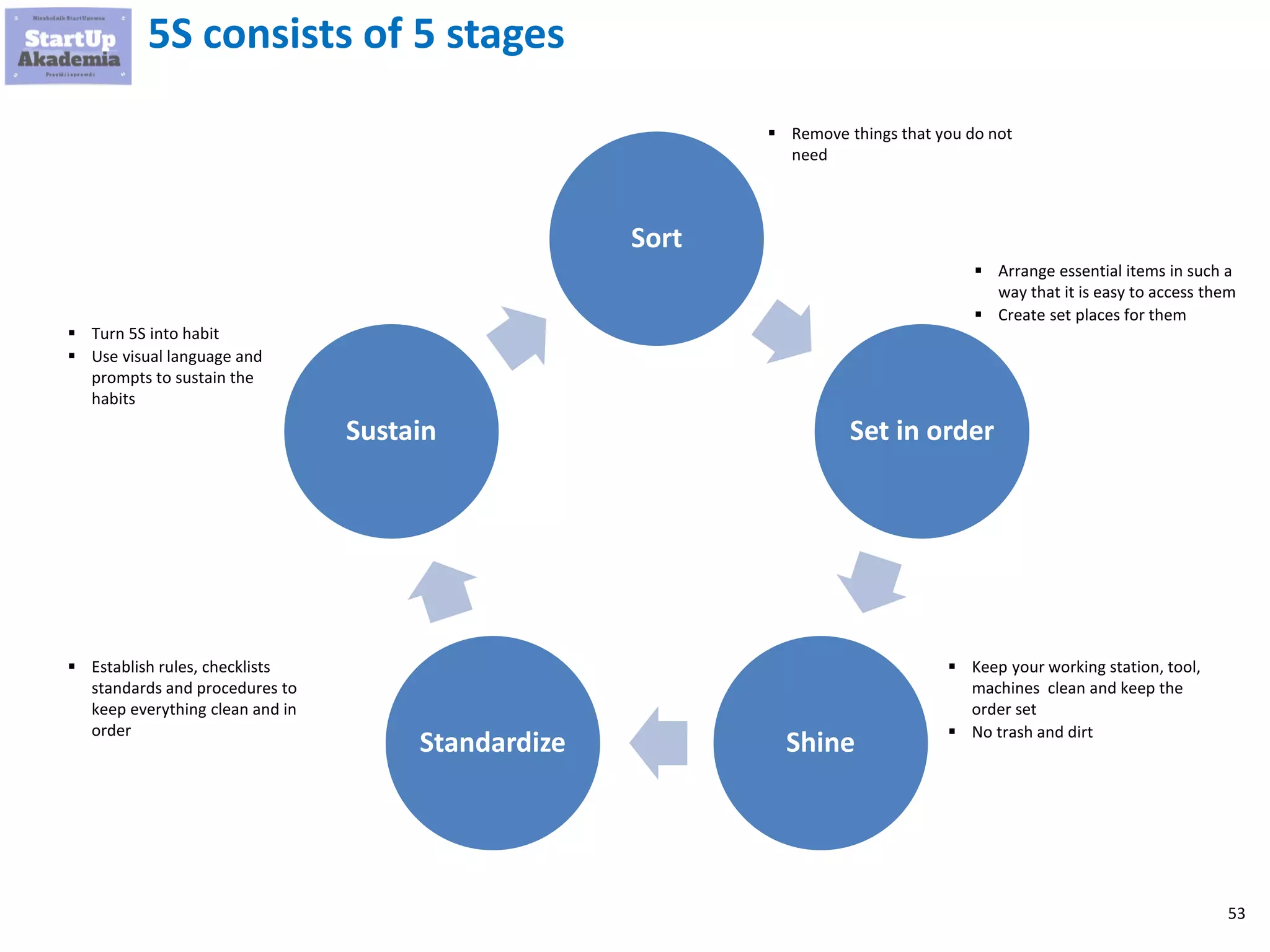

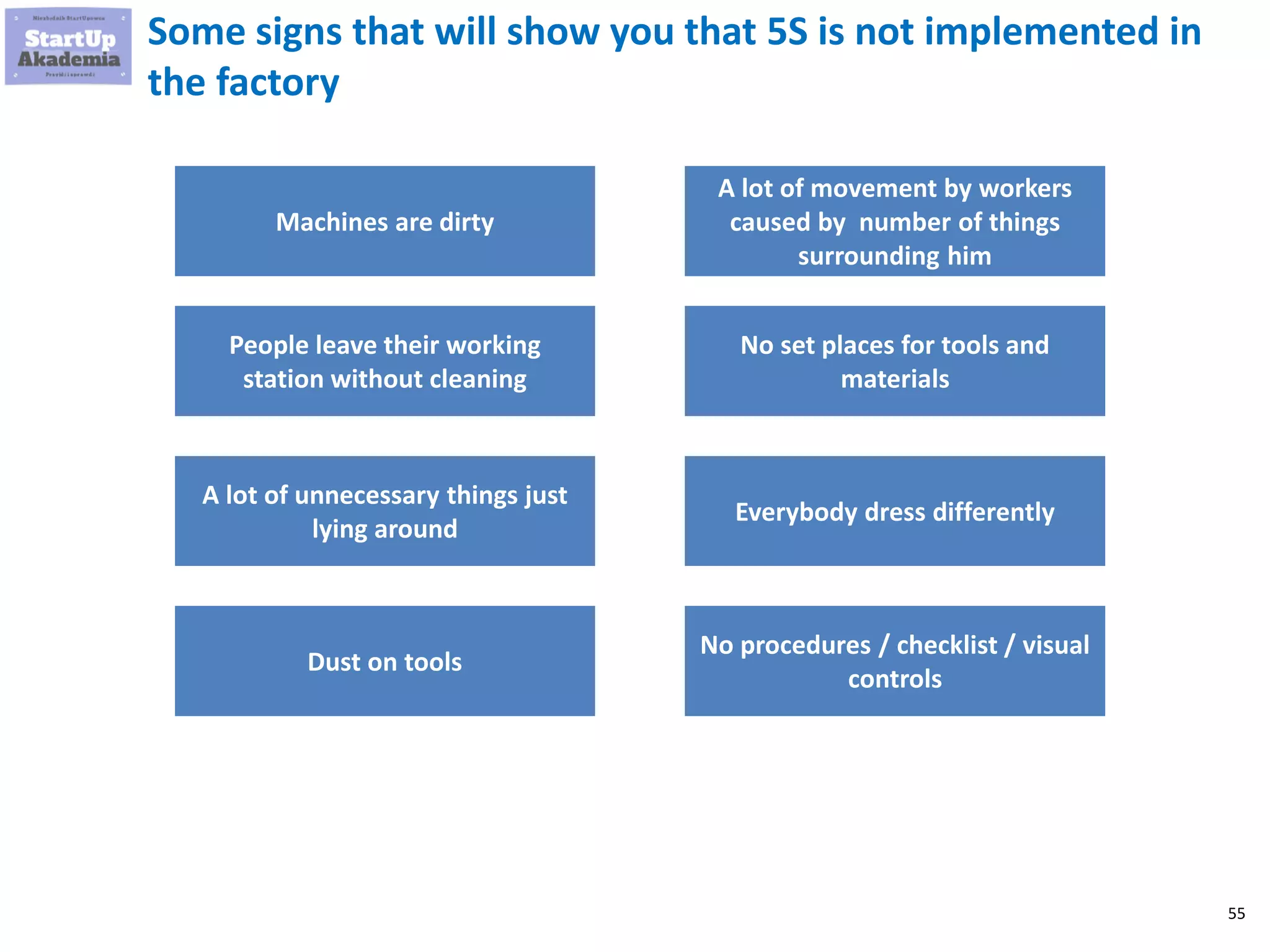

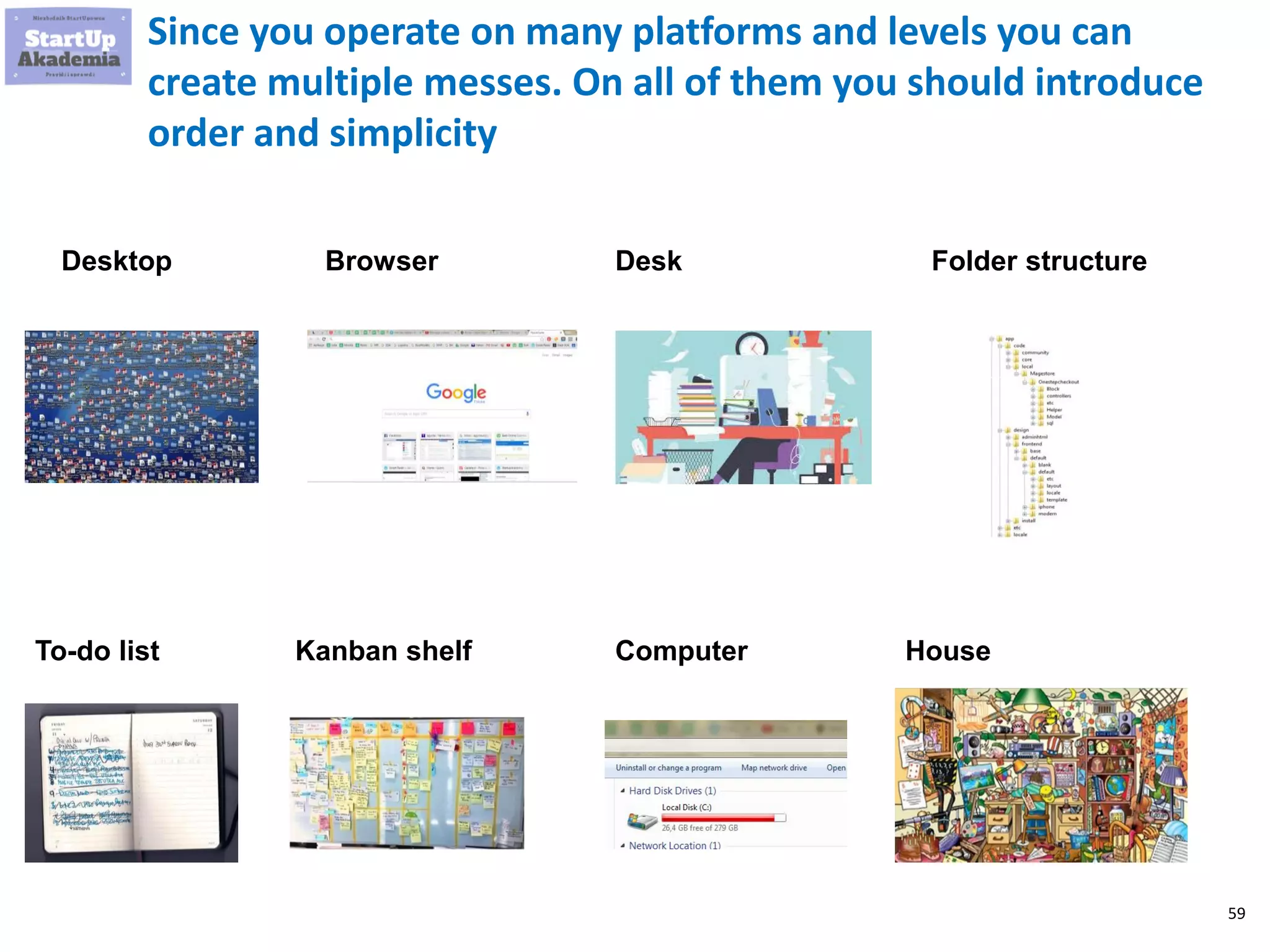

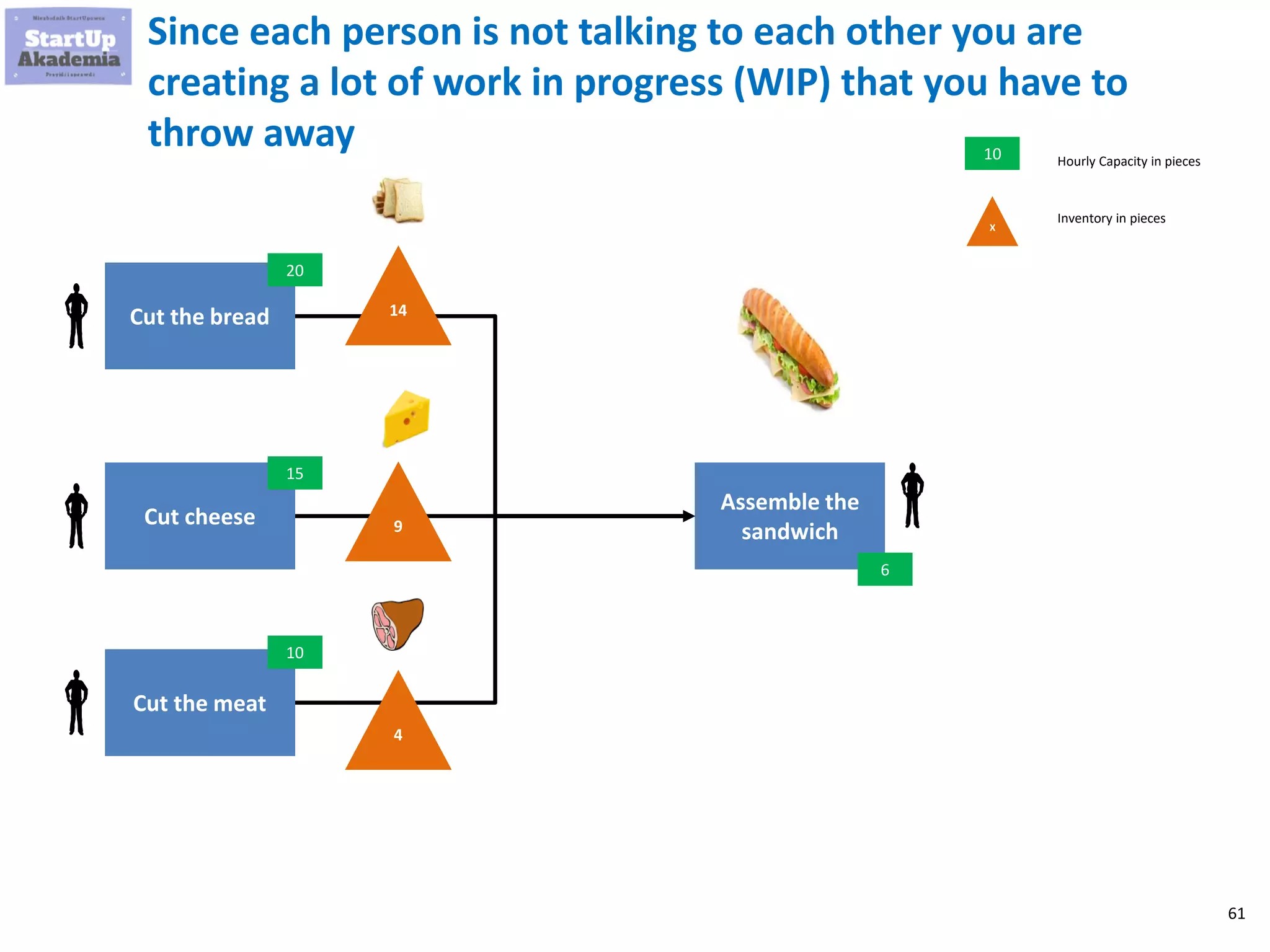

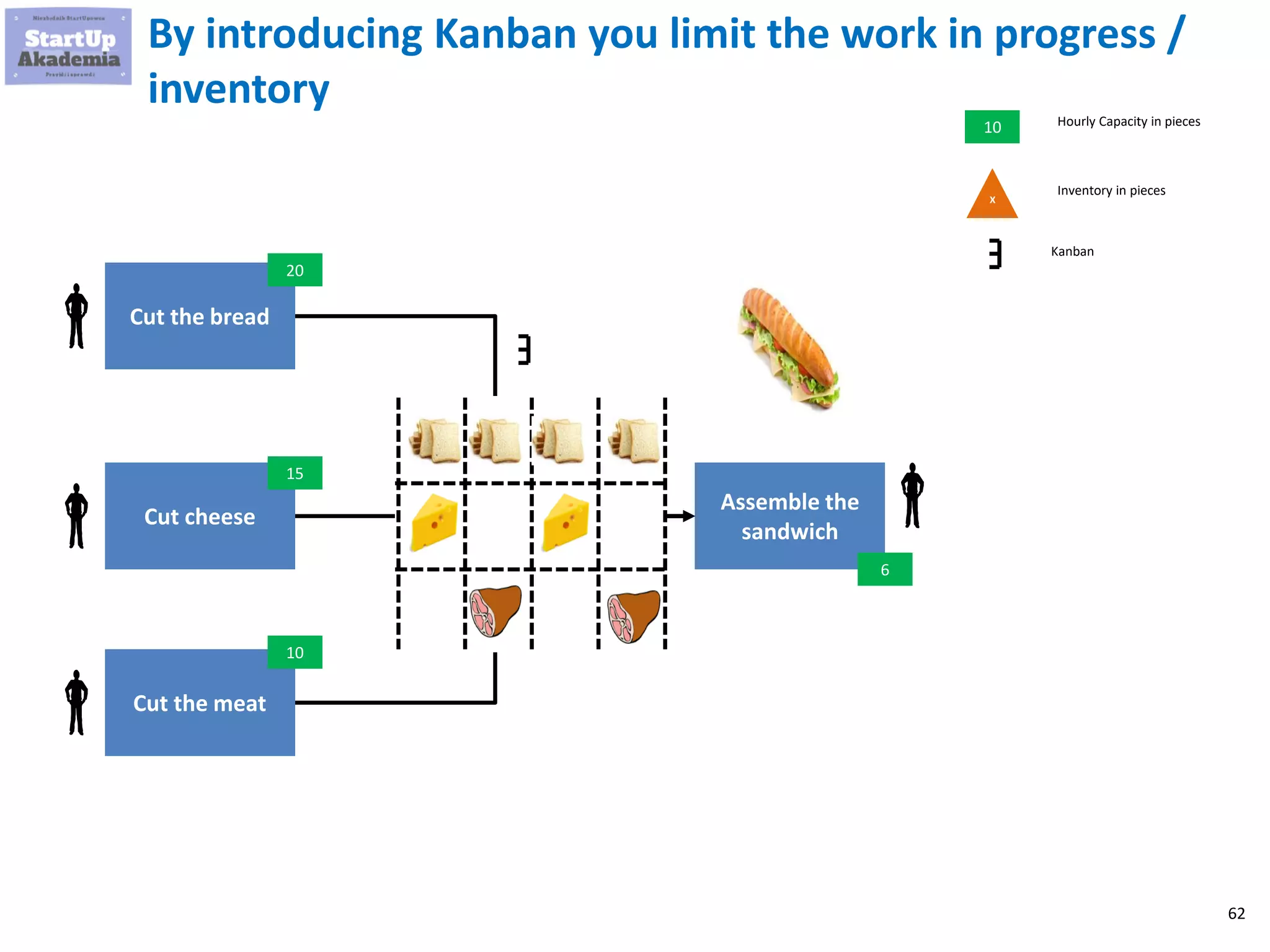

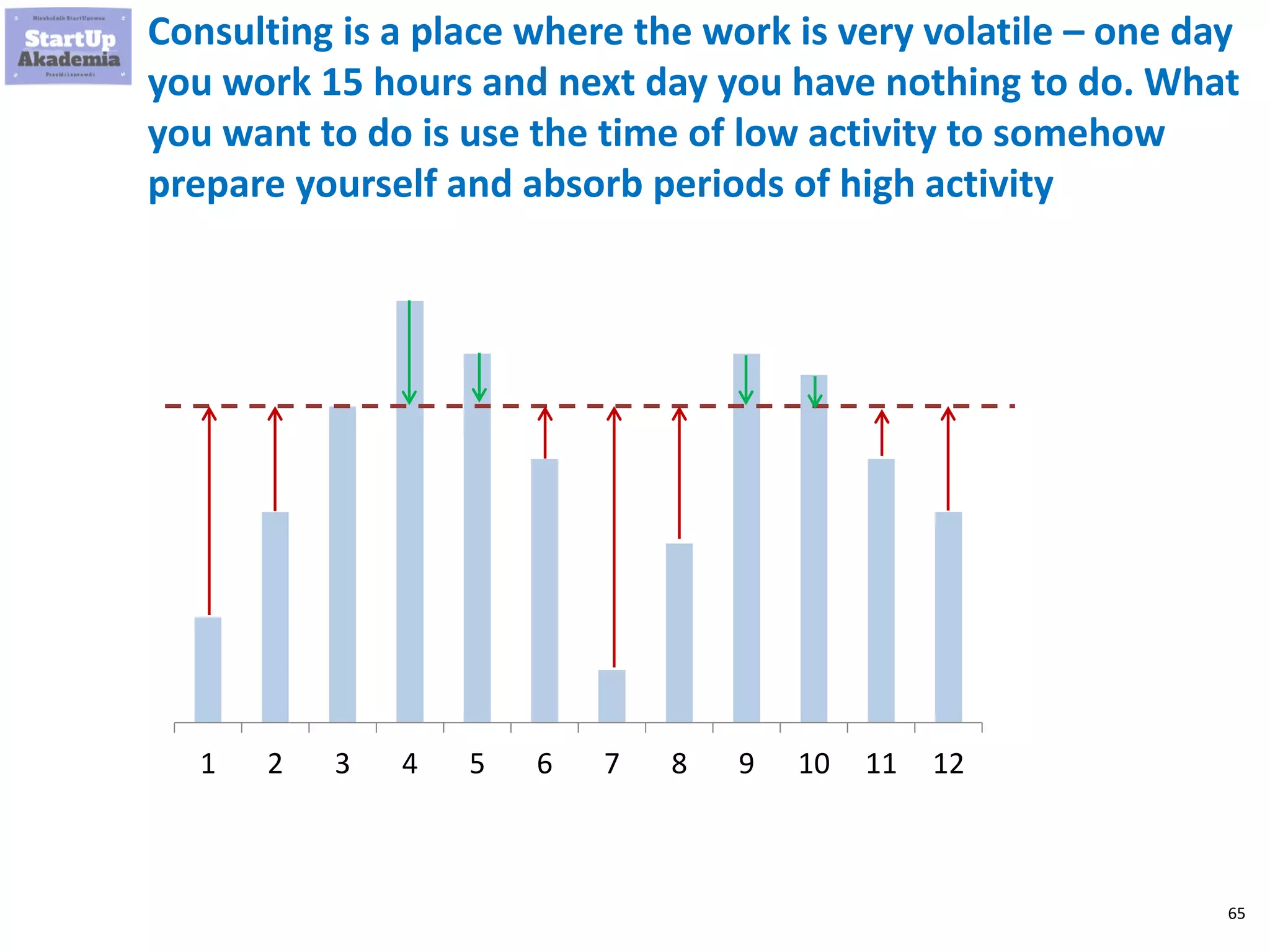

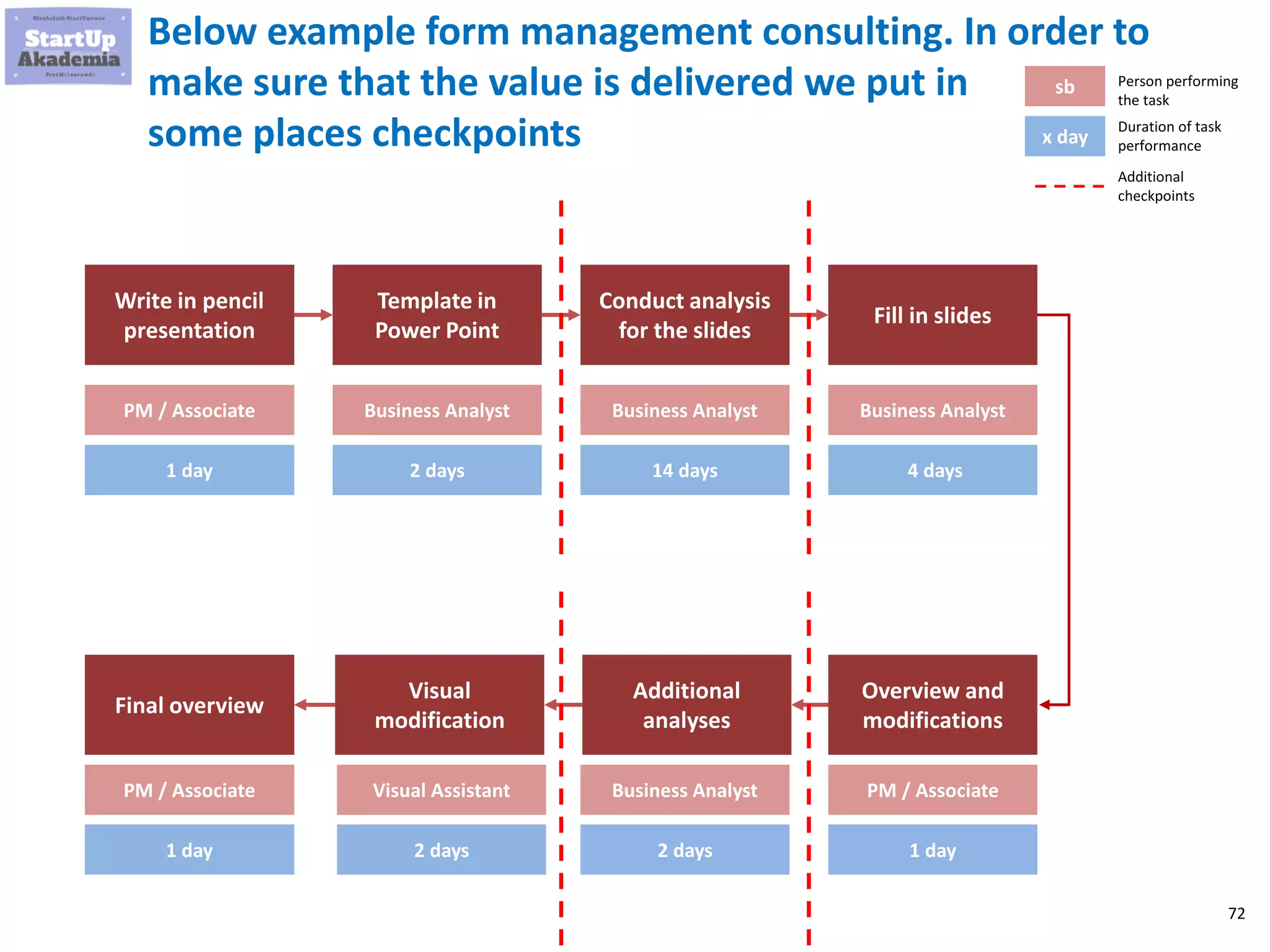

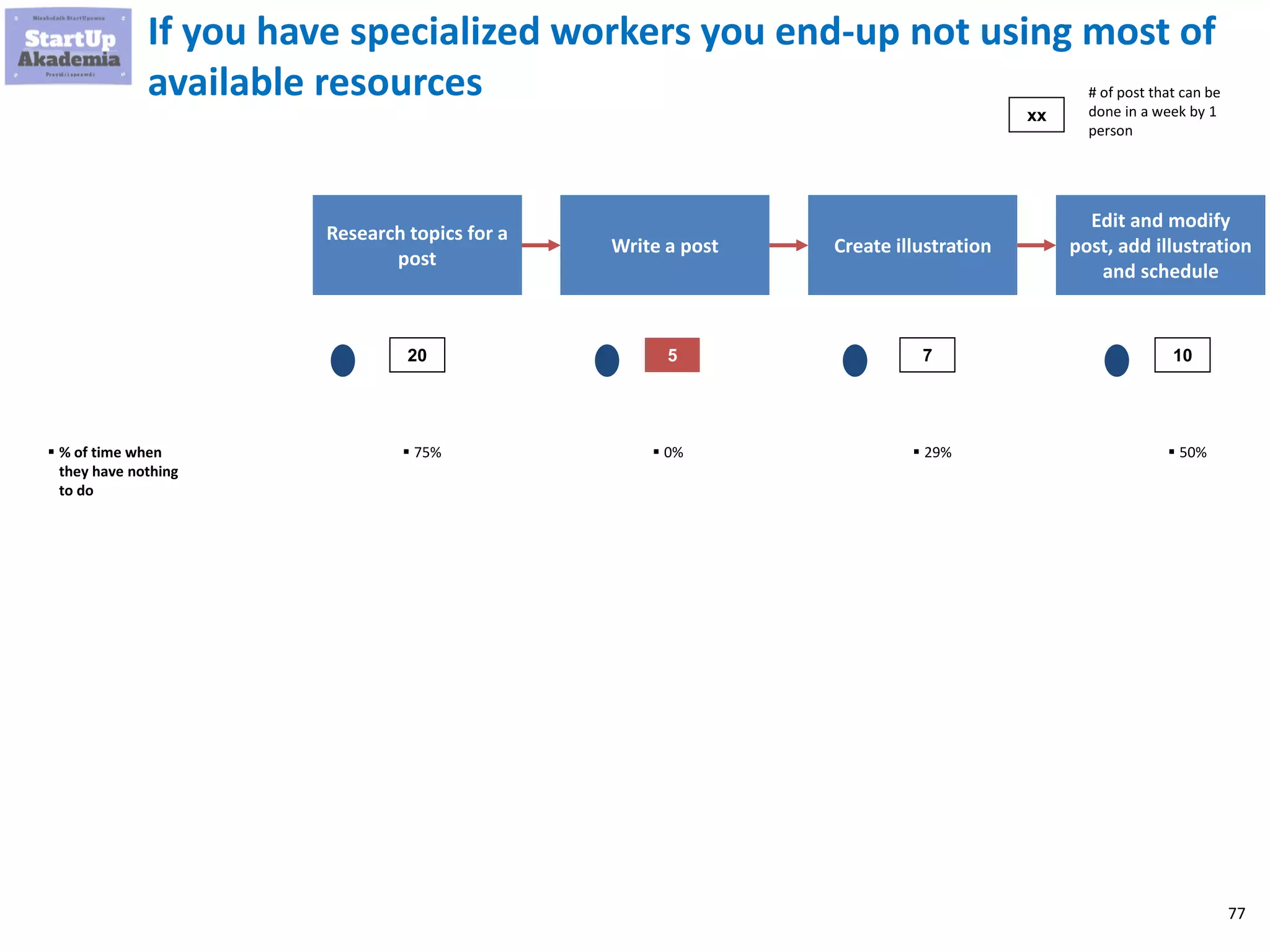

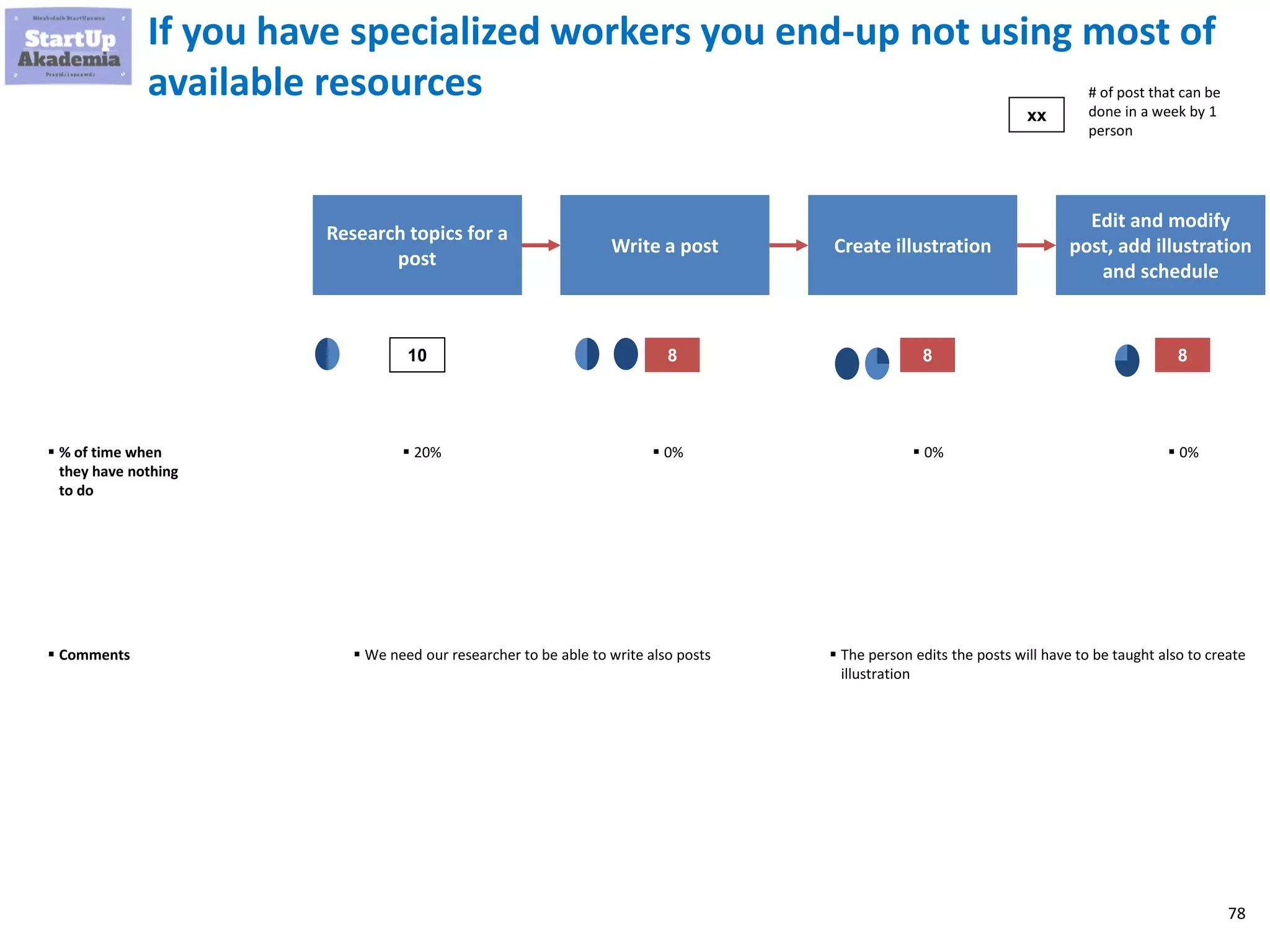

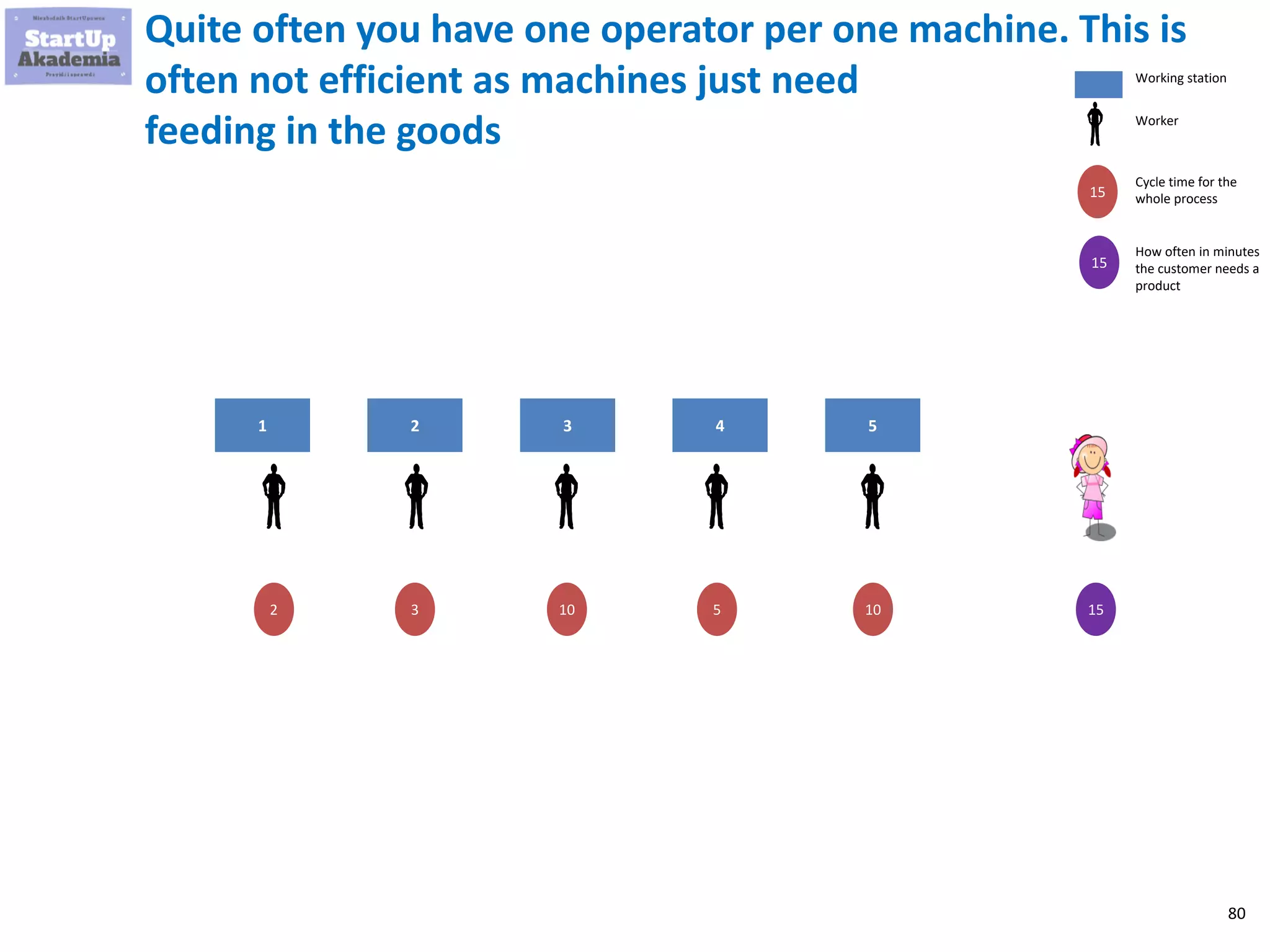

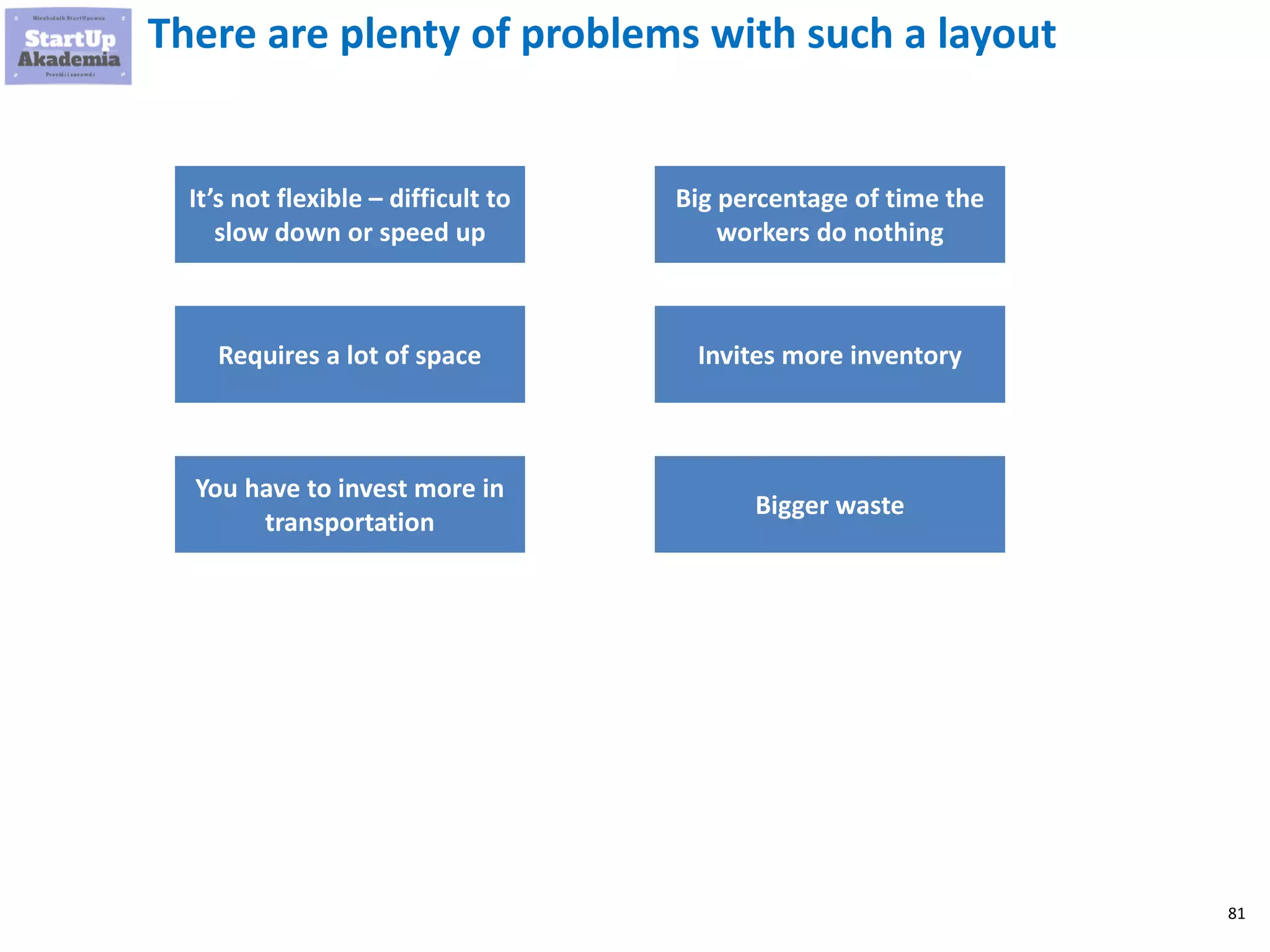

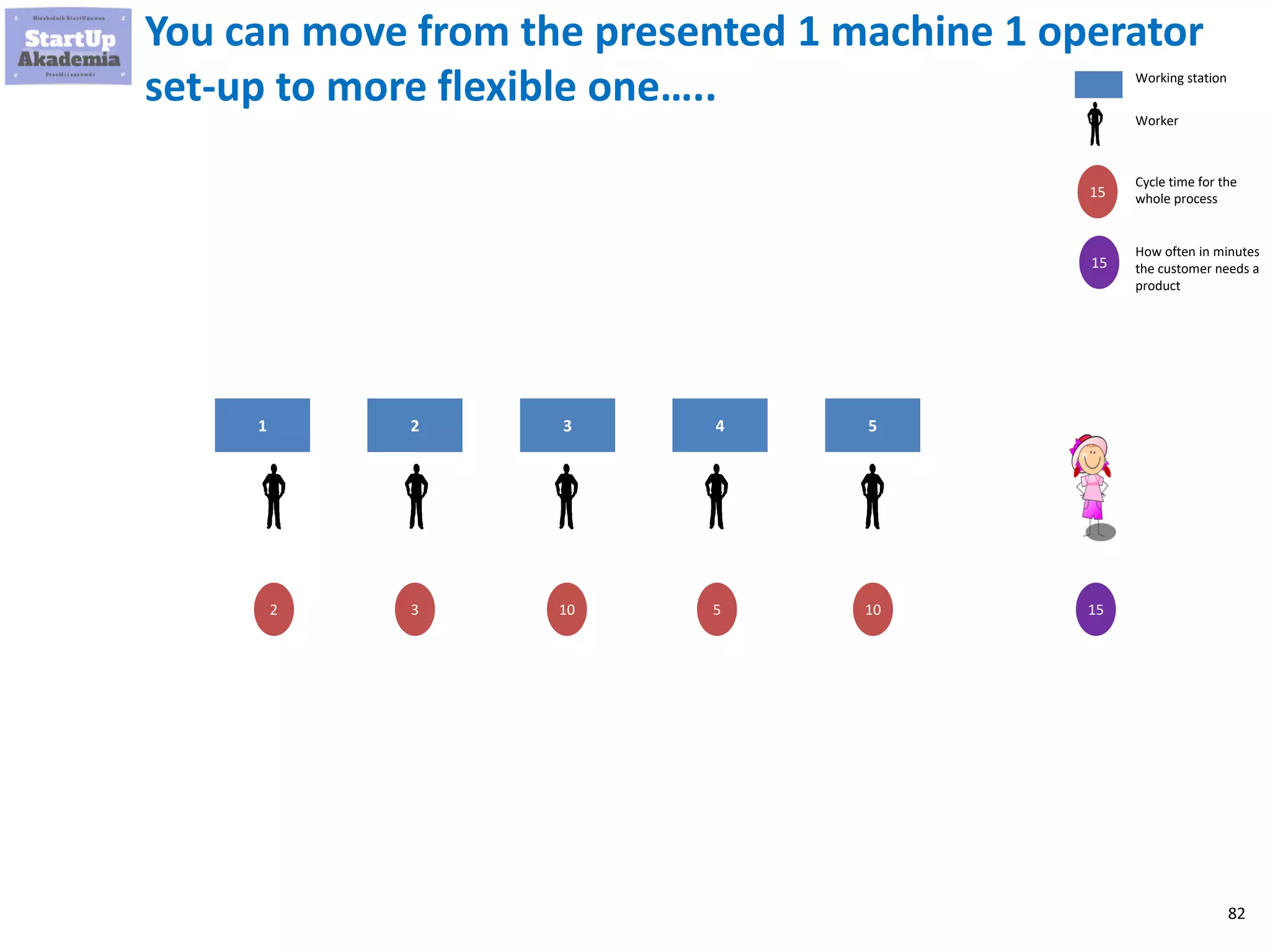

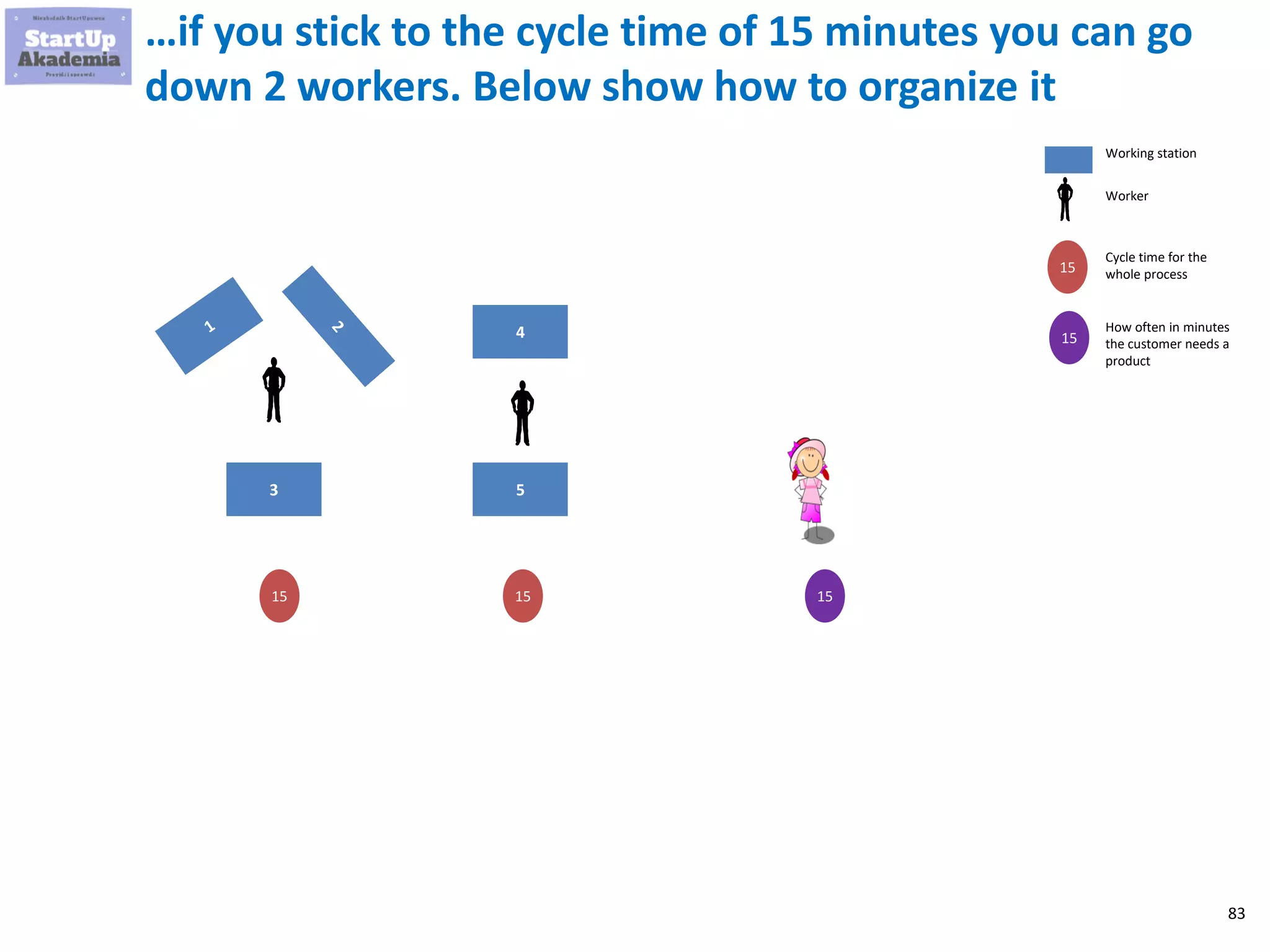

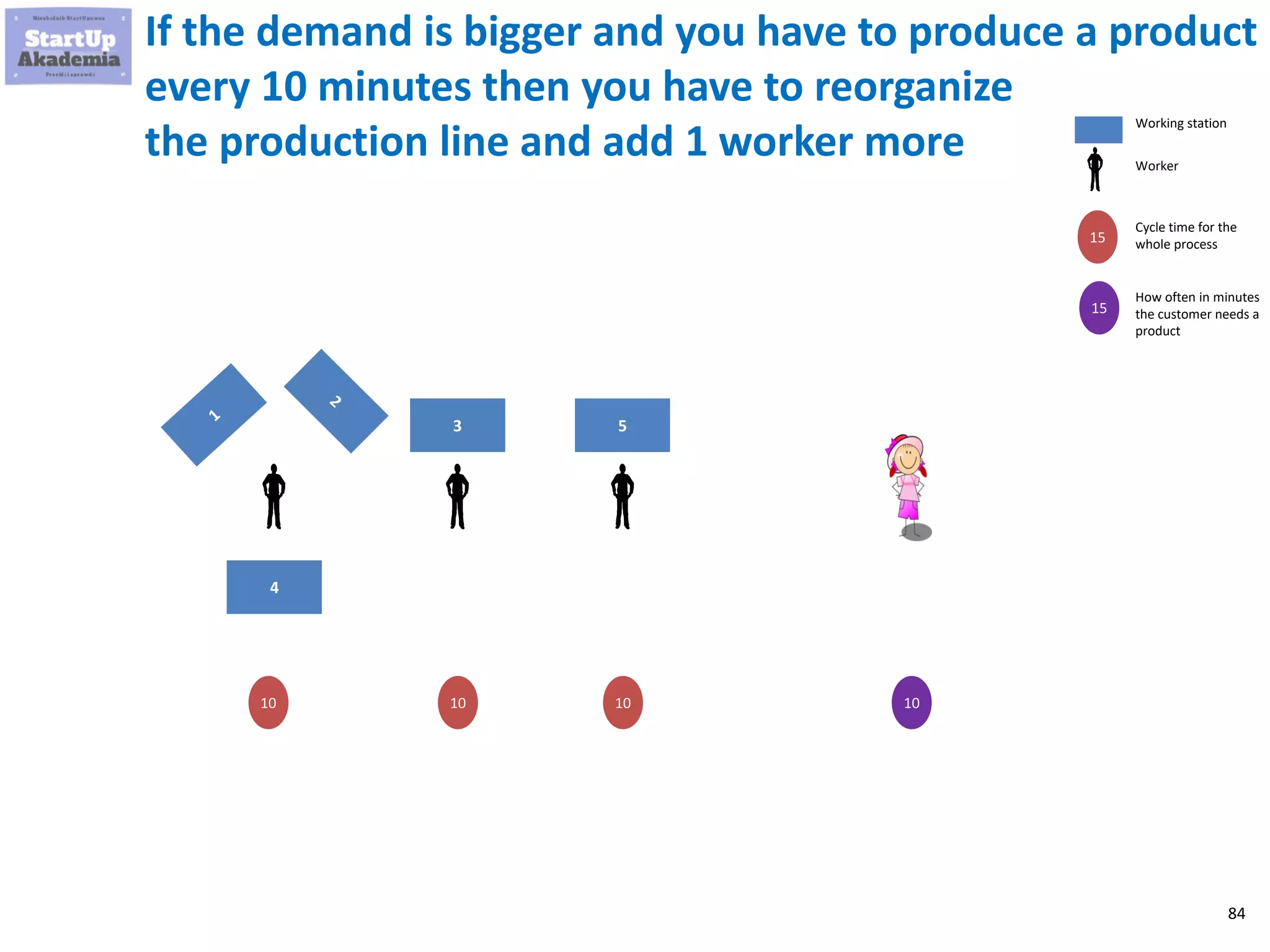

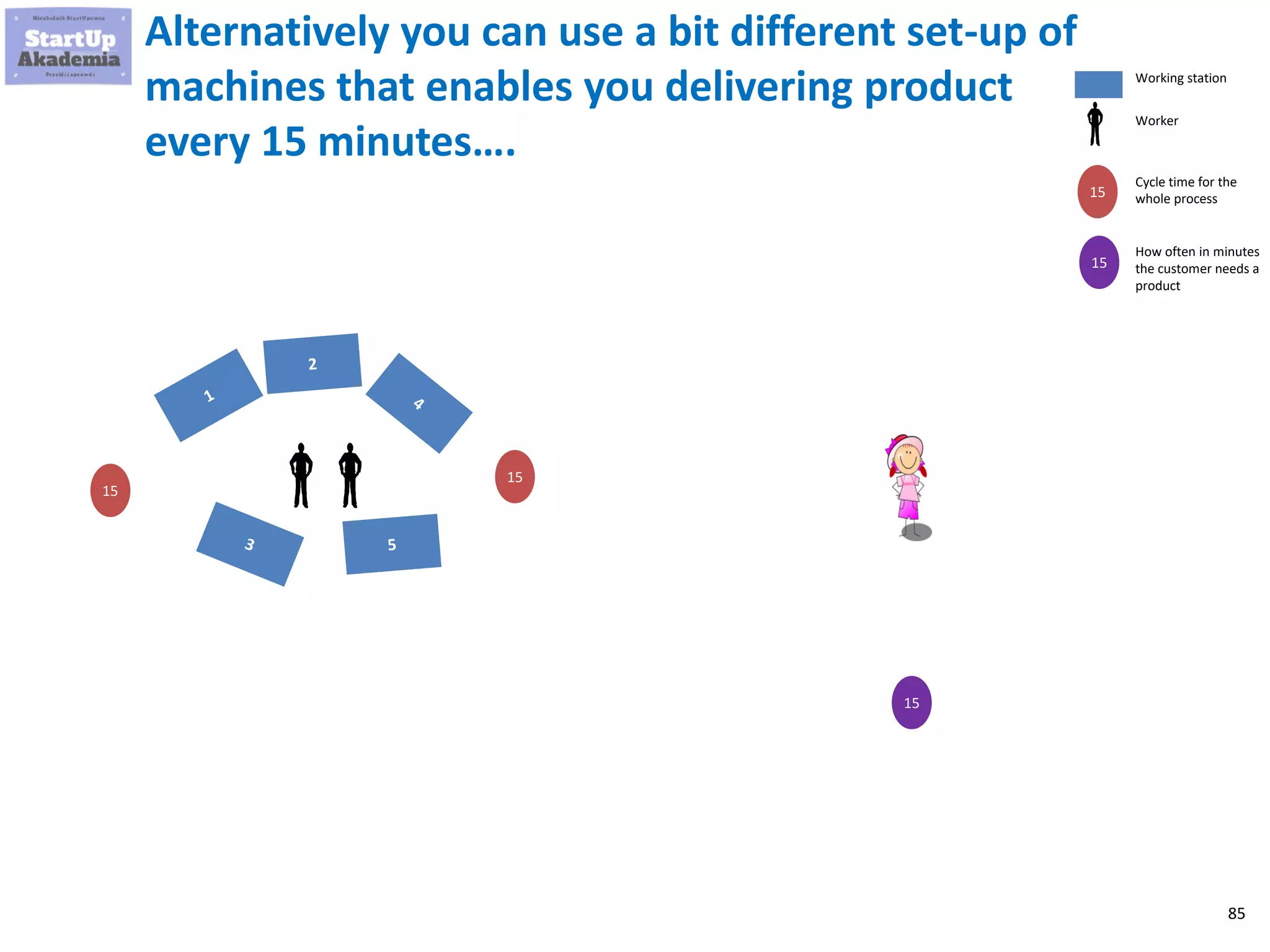

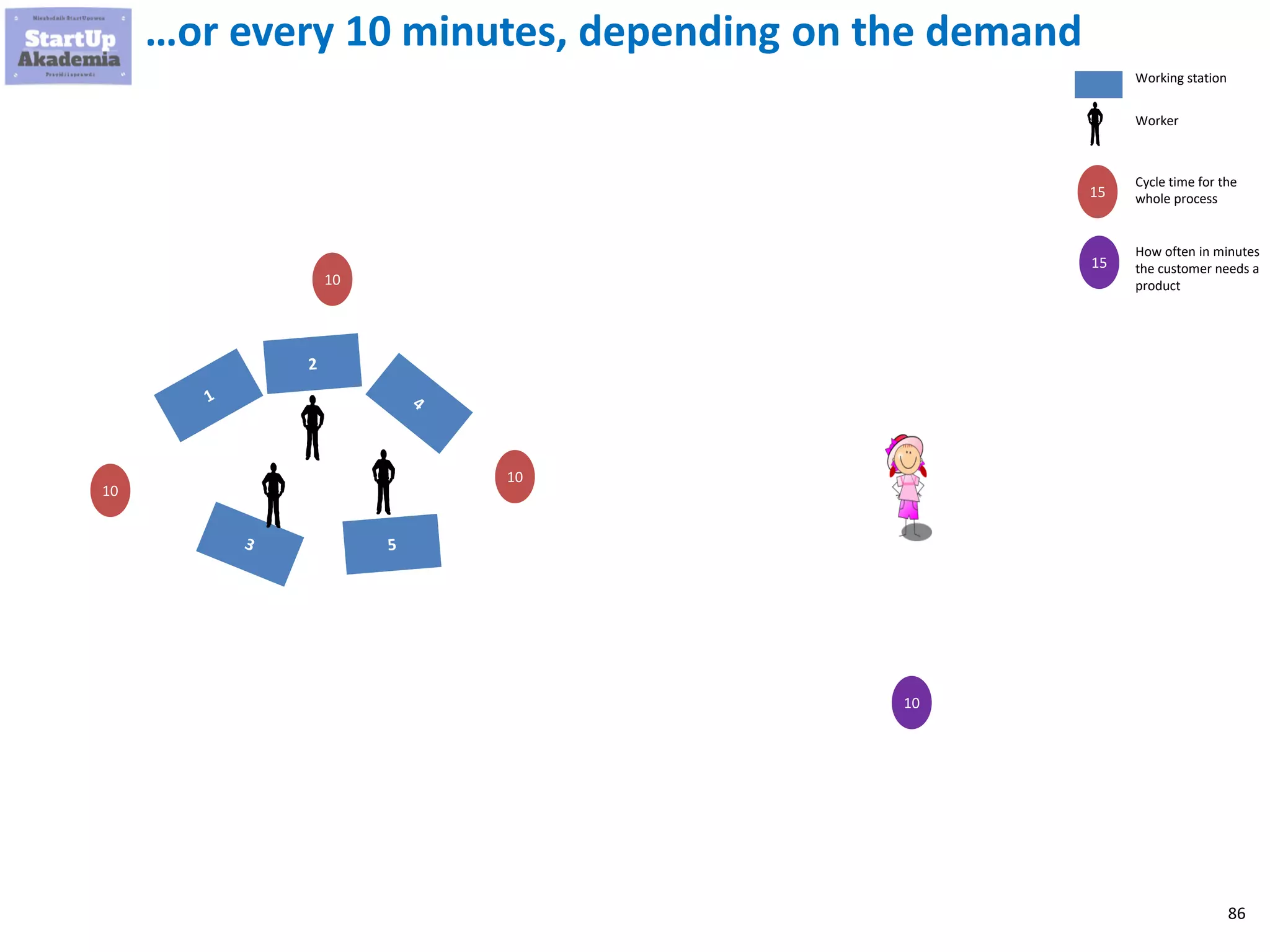

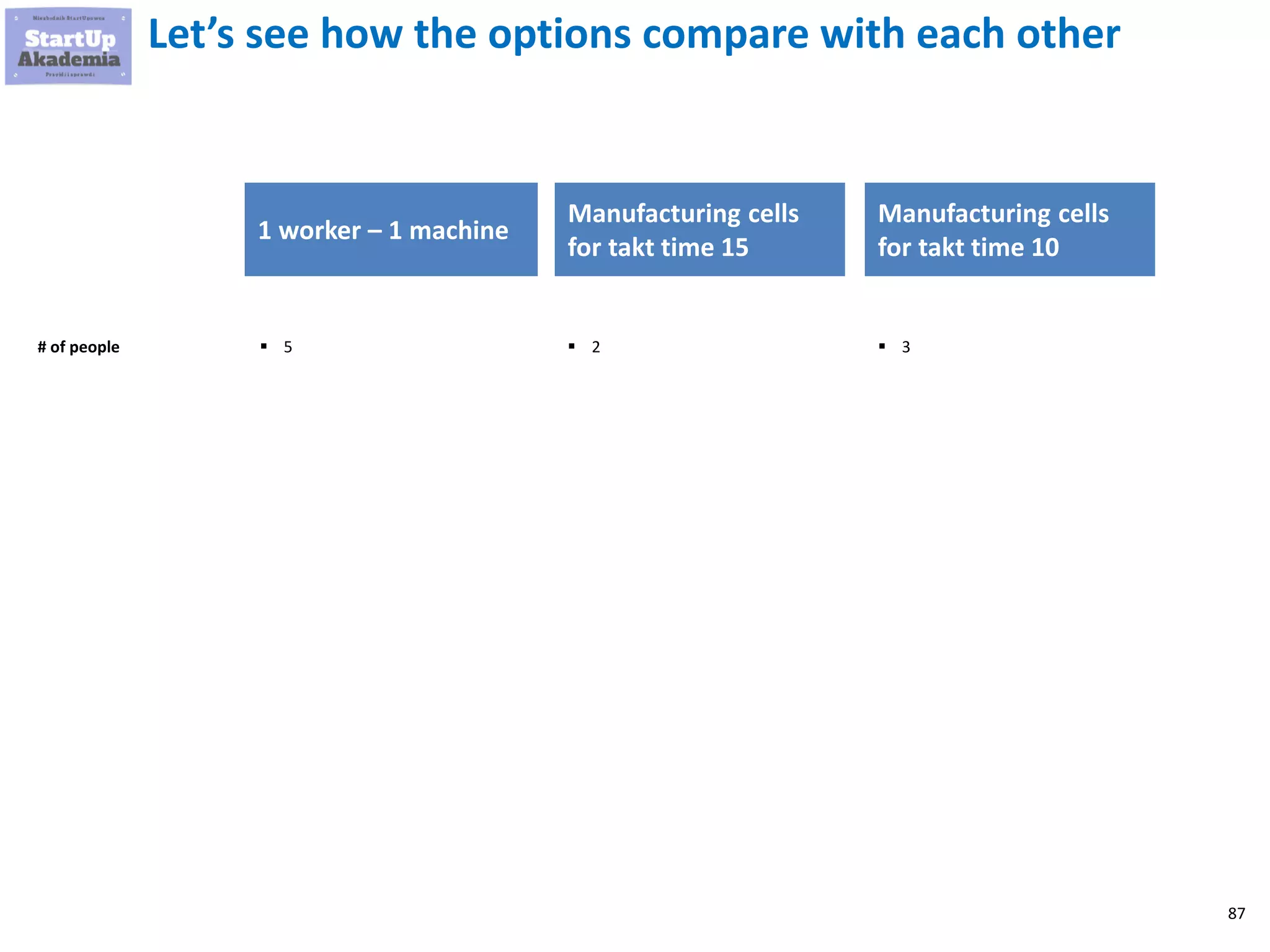

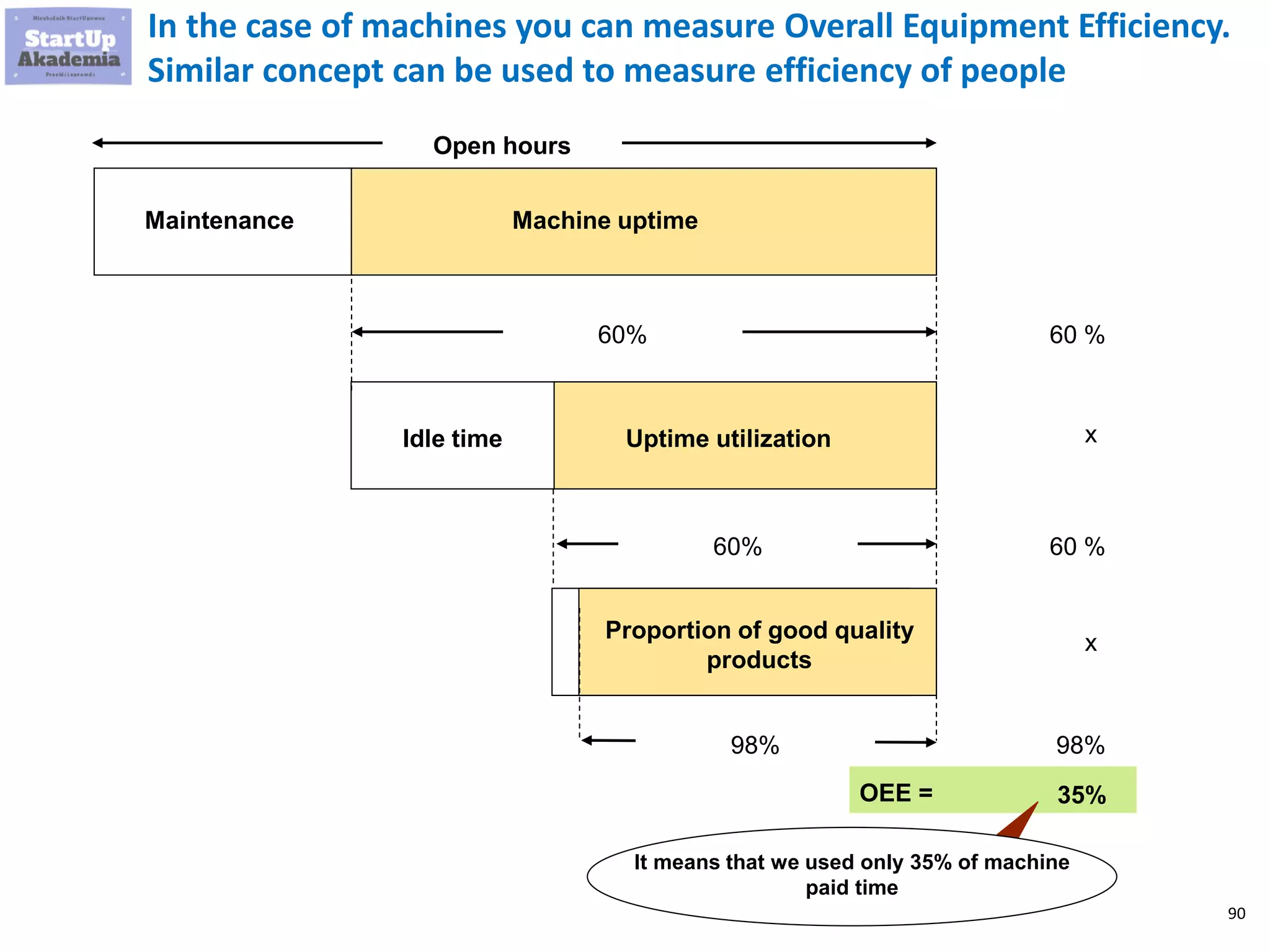

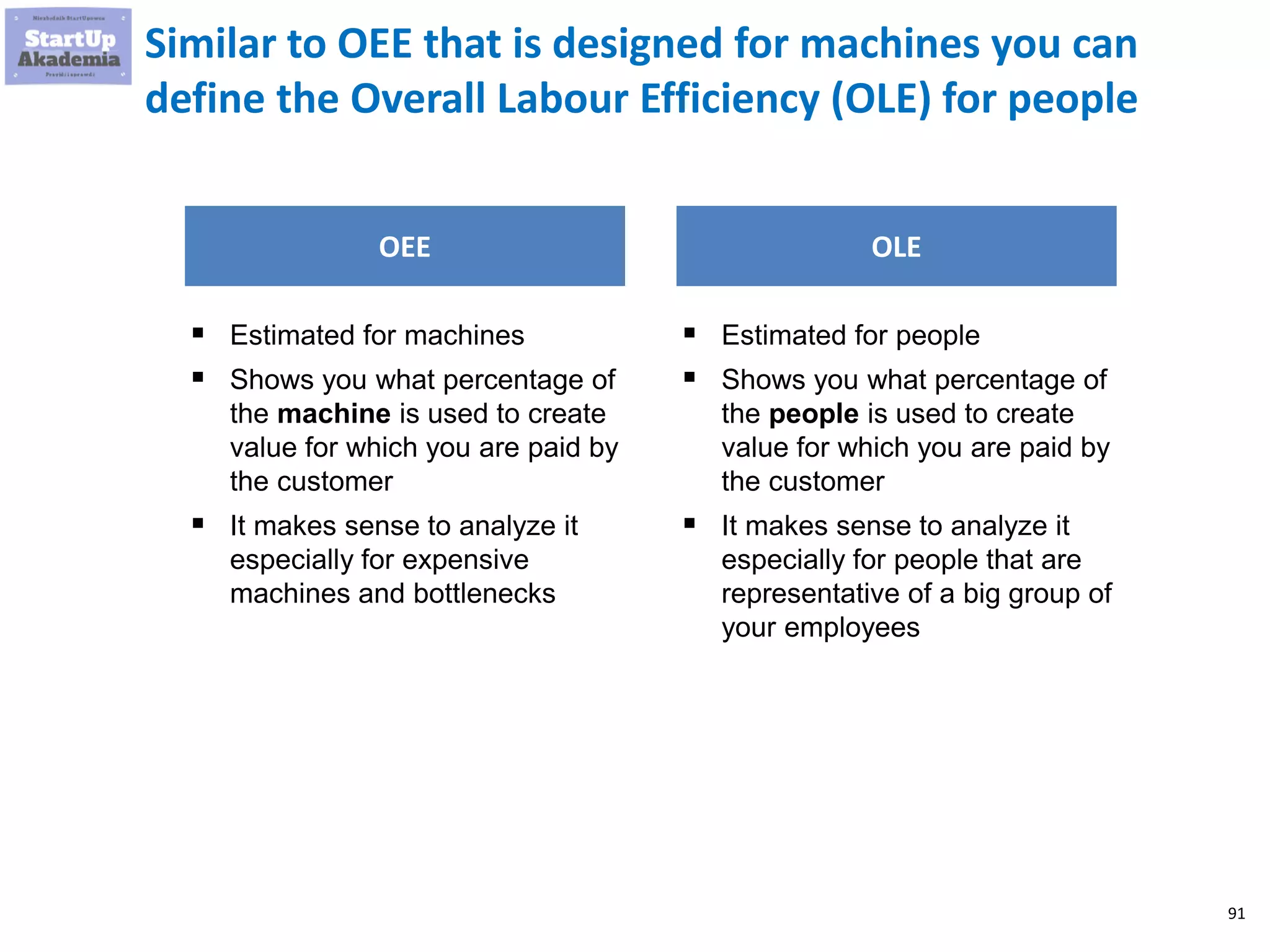

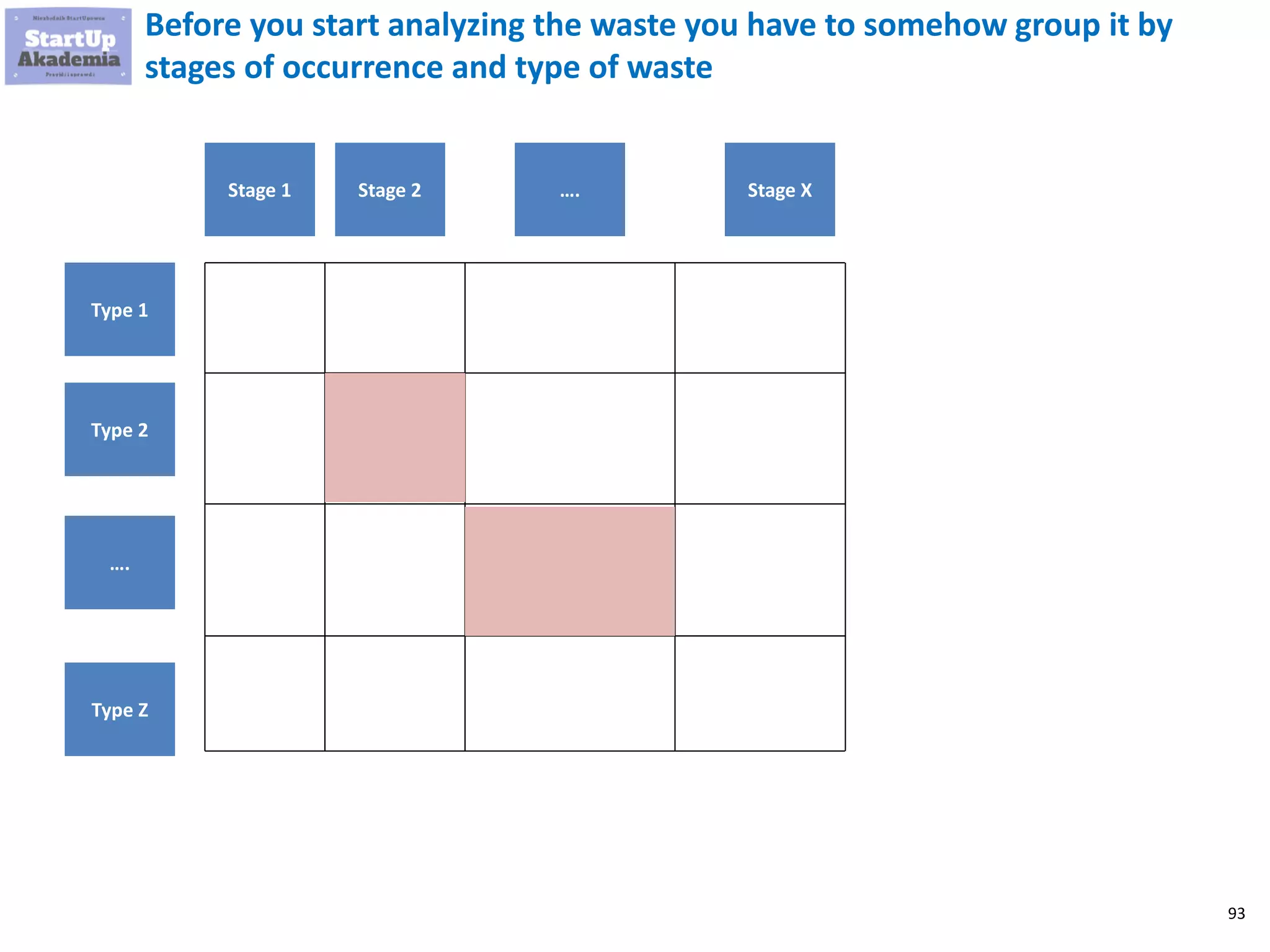

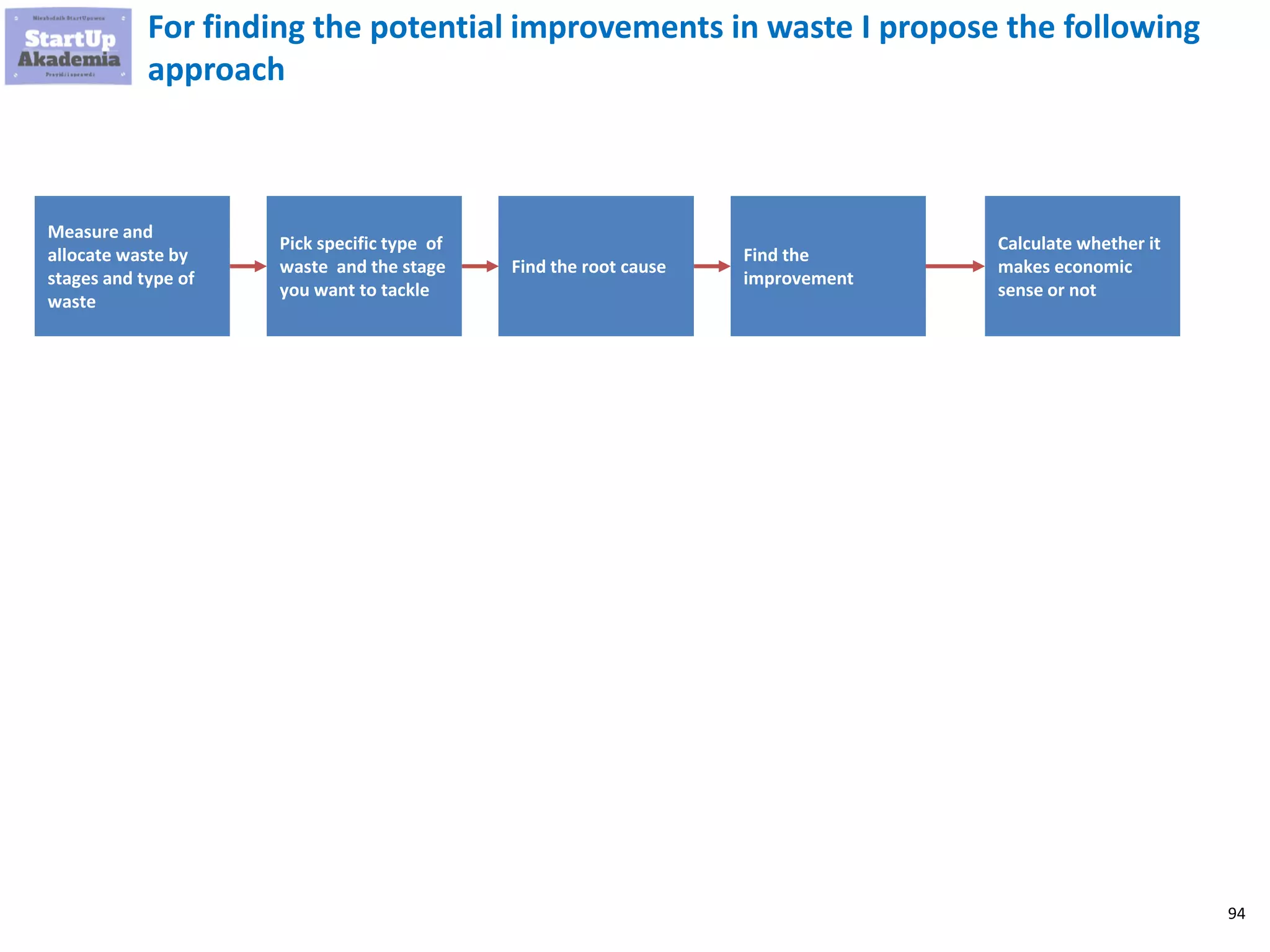

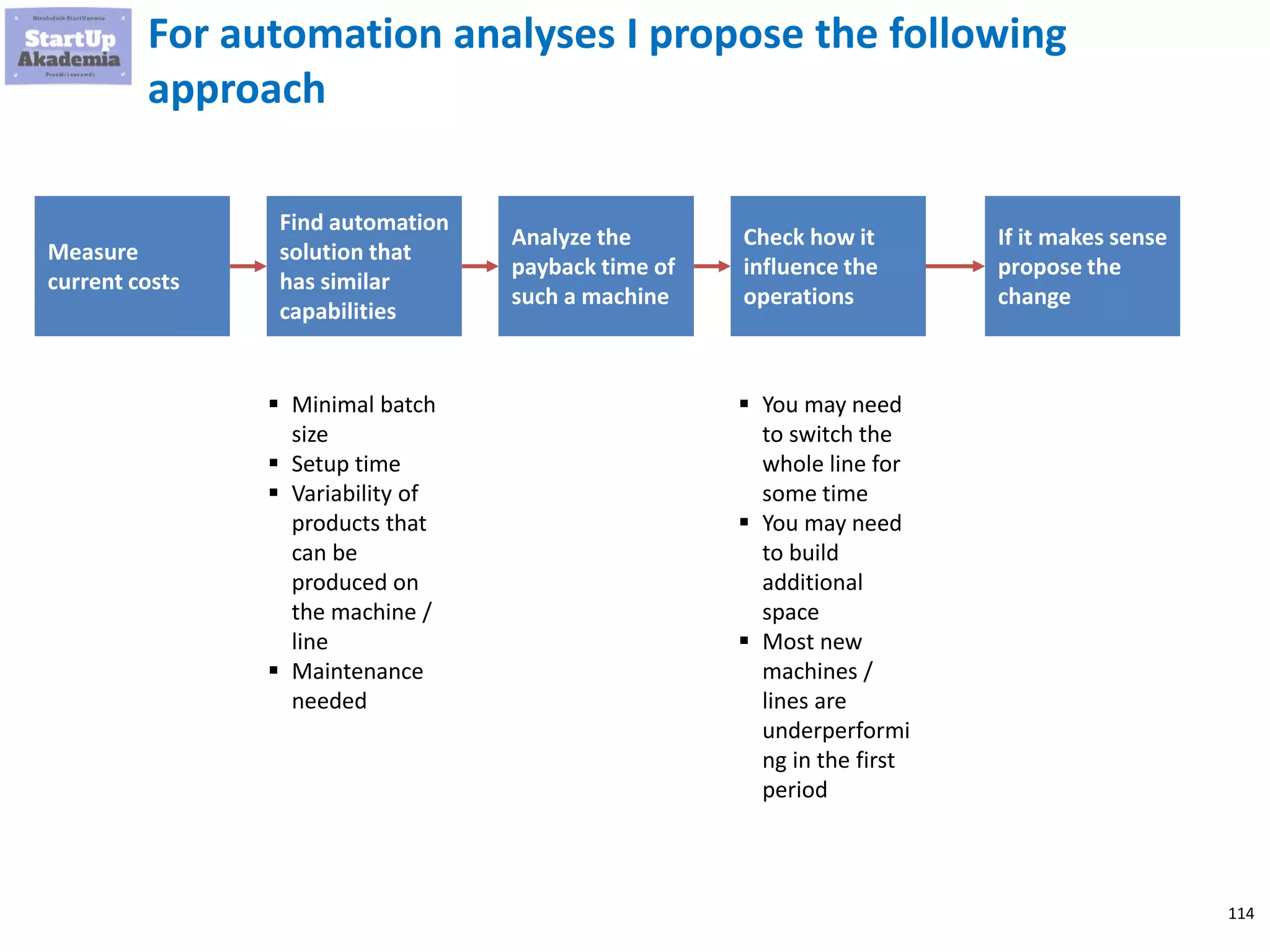

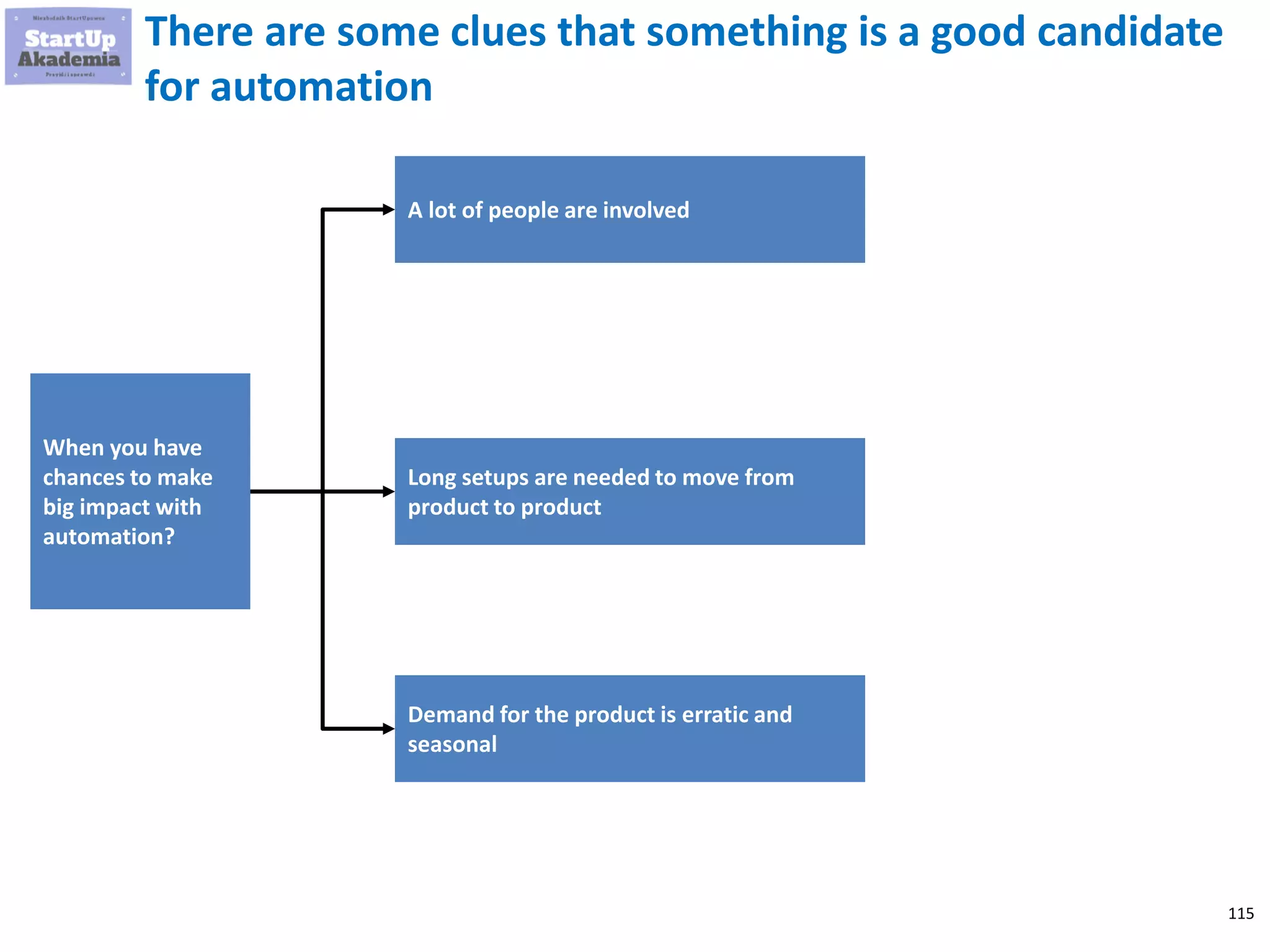

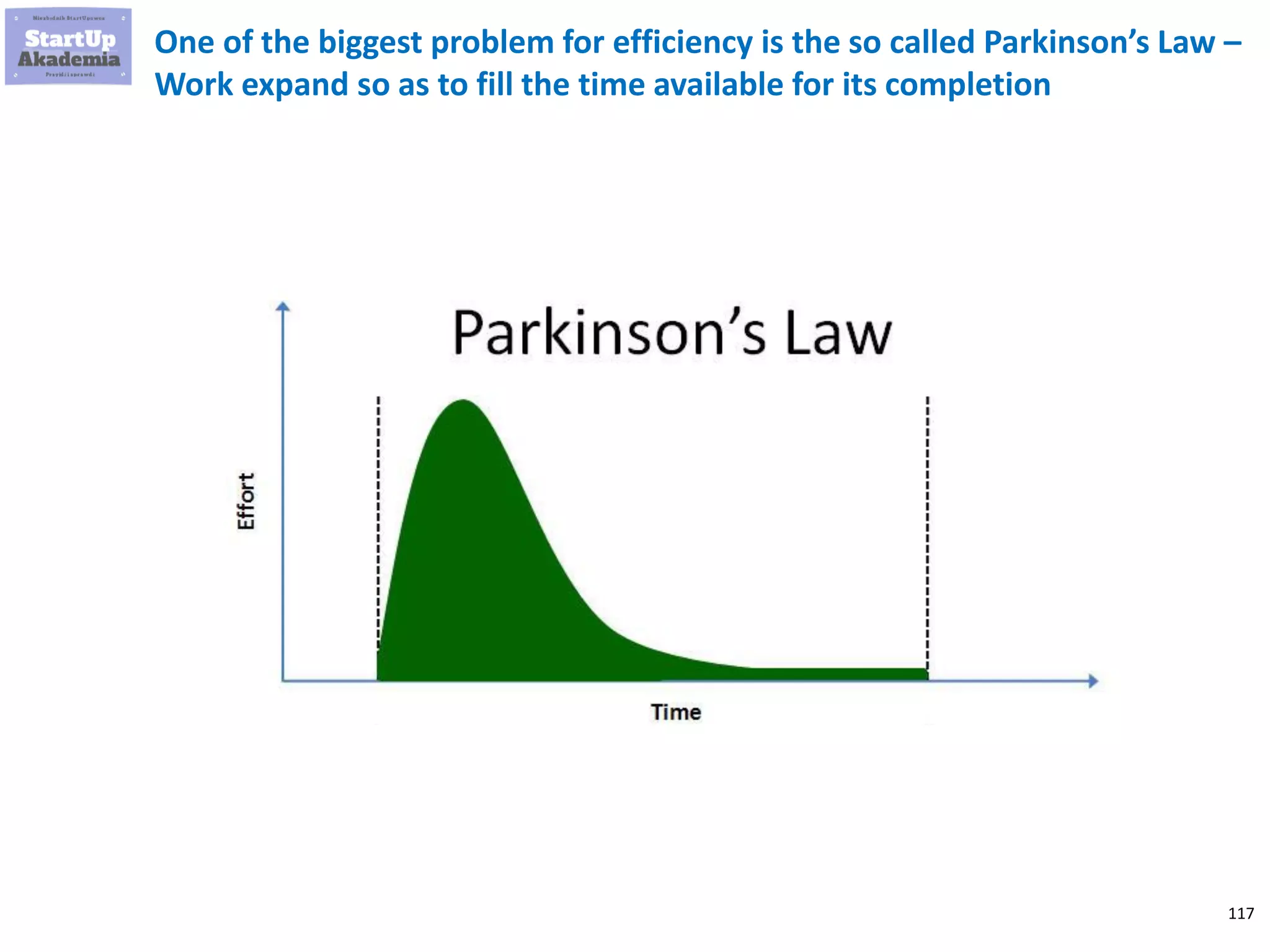

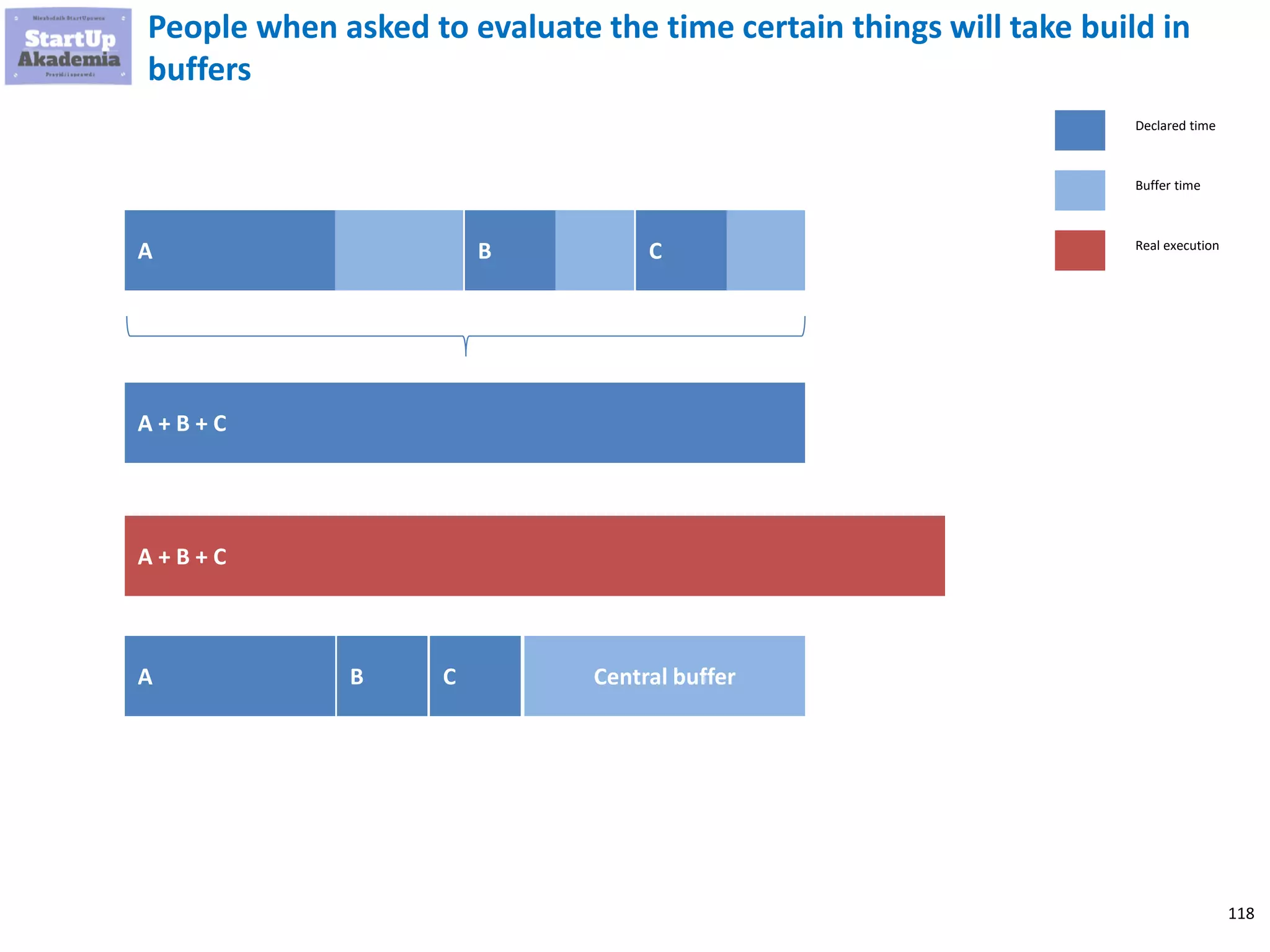

This document provides an overview of lean manufacturing techniques for improving production processes. It discusses concepts like overall equipment effectiveness (OEE), theory of constraints, continuous flow, standardization, 5S, kanban, and waste analysis. Examples are provided to illustrate how to identify and reduce different types of waste in production. The document also includes a case study example of improving processes in a sandwich factory by implementing divisions of labor, standardizing cycle times, and establishing kanban systems.