This document provides definitions and information related to risk analysis. It defines key terms like hazard, risk, risk analysis, risk assessment, and reliability. It discusses various quantitative and qualitative methods for risk analysis including fault tree analysis, failure mode and effects analysis, and hazard and operability studies. Failure rate data for some process components is also presented. The document provides an overview of important concepts in quantitative risk analysis including reliability, mean time between failures, and interaction between equipment for series and parallel systems. Overall it serves as a reference on the topic of risk analysis, defining key terms and outlining various approaches.

![Availability is The degree to which a system, subsystem, or equipment is operable

and in a committable state at the start of a mission, when the mission is called for at

an unknown, i.e., a random, time. Simply put, availability is the proportion of time

a system is in a functioning condition

Mathematically, A = E [uptime]

E [uptime] + E [downtime]

ENVIRONMENT (PROTECTION) ACT,1986

The central government, by notification in the official gazette, has notified under

Section 6(2)

(c) the procedures and safeguards for the handling of hazardous substances

(d) the prohibition and restrictions on the handling of hazardous substances in

245

different areas

(f) the procedures and safeguards for the prevention of accidents which may

cause environmental pollution and for providing for remedial measures for

such accidents

Under the Environment (Protection) Rules, 1986, Clause 13(l) the following factors are

to be considered while prohibiting and restricting the handling of hazardous substances

The hazardous nature of the substances in terms of its damage causing potential

to the environment, human beings, other living creatures, plants and property

The substances that may be or likely to be readily available as substitutes for the

substances proposed to be prohibited or restricted

The indigenous availability of the substitute, or the state of technology available

in the country for developing a safe substitute

The gestation period that may be necessary for gradual introduction of a new

substitute with a view to bringing about a total prohibition of hazardous

substances in question

Any other factor that may be considered by the central government to be

relevant to the protection of the environment

CODES STANDARDS FOR RISK ANALYSIS

American Institute of Chemical Engineers have Guidelines for Chemical

Process Quantitative Risk Analysis Hazard Evaluation Procedures, OSHA

has 29 CFR 1910.119, EPA Risk Management Plan (RMP)

Even in non chemical industries codes like Nuclear Regulatory Commission

NUREG/CR-2815 , IEC 61508, SEMI S10 - Safety Guideline for Risk

Assessment, S14 - Safety Guide for Fire Assessment Mitigation for

Semiconductor Manufacturing Equipment

India has its own BIS guidelines for risk assessment in BIS 18001 and also

guidelines by labor ministry, Factories act etc.

This standard prescribes requirements for an OHS Management Systems to

enable an organization to formulate a policy and objectives, taking into account

legislative requirements and information about significant hazards and risks,

which the organization can control and over which it can be expected to have

an influence, to protect its employees and others, whose health and safety may

be affected by the activities of the organization. All the requirements in this

standard are intended to be incorporated into any OHS management system.

This standard also provides imperative guidance on the use of the specification](https://image.slidesharecdn.com/08riskanalysis-140920135027-phpapp02/85/risk-analysis-2-320.jpg)

![1 =Õ [ 1 - exp i (-l t) ]

253

n

P =Õ P i

i

n

R = 1 -Õ (1 - Ri) =

i

n

1

i

QUANTITATIVE TECHNIQUES

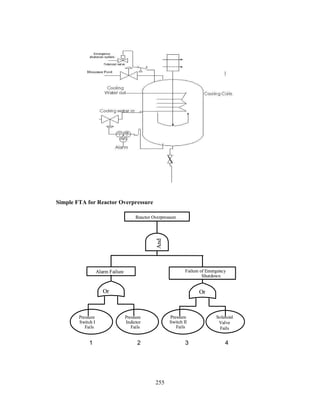

Fault Tree Analysis

A fault tree is a logical diagram which shows the relation between system

failure, i.e. a specific undesirable event in the system, and failures of the

components of the system

It is a technique based on deductive logic. An undesirable event is first defined

and causal relationships of the failures leading to that event are then identified

Fault Tree analysis

Fussel (1976) notes that the fault tree analysis is of major value in

Directing the analyst to ferret out failures deductively

Pointing out the aspects of the system important in respect of the failure of

Interest

Providing a graphical aid giving visibility to those in system management who

are removed from system design changes

Providing options for qualitative on quantitative system reliability analysis

Allowing the analyst to concentrate on one particular system failure at a time

Providing the analyst with genuina insight into system behaviour

Basic Rules For Fault Tree Construction

Ground Rule 1

Write the statements that are entered in the event boxes as faults; state precisely what

the fault is and when it occurs

Ground rule 2

If the answer to the question, Can this fault consist of a component failure? is Yes,

classify the event as a stat-of-component fault. If the answer is No”. Classify the

event as a state-of-system fault

No Miracles Rule

If the normal functioning of a component propagates a fault sequence, then it is

assumed that the component functions normally

Generating Fault Trees

Complete-the-Gate rule

All inputs to a particular gate should be completely defined before further

'analysis of anyone of them is undertaken.

No Gate-to-Gate Rule

Gate inputs should be properly defined fault events, and gates should not be

directly connected to other gates](https://image.slidesharecdn.com/08riskanalysis-140920135027-phpapp02/85/risk-analysis-10-320.jpg)