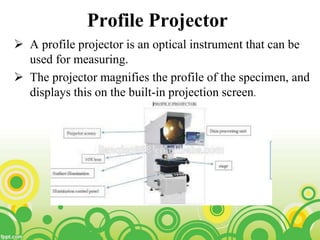

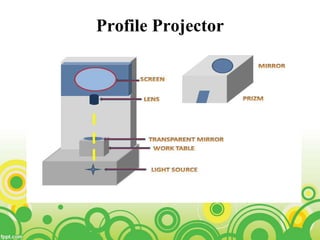

This document is a presentation on profile projectors. It discusses that a profile projector is an optical instrument used for measuring by magnifying a specimen's profile and projecting it onto a screen. There are three main types - bench, vertical, and horizontal. The document outlines the history, working principle, procedures for use, types, applications, advantages such as time and cost savings, and limitations such as it being a fixed device.