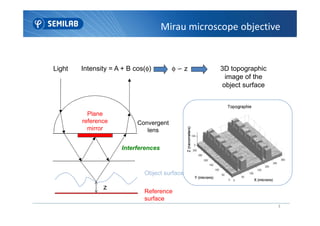

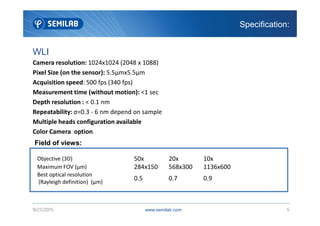

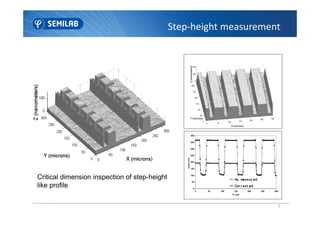

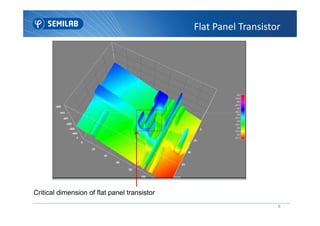

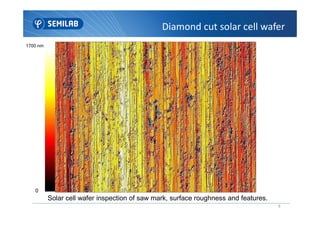

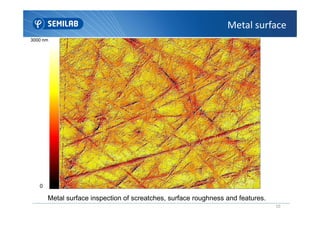

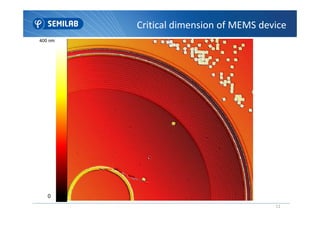

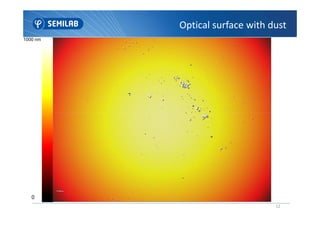

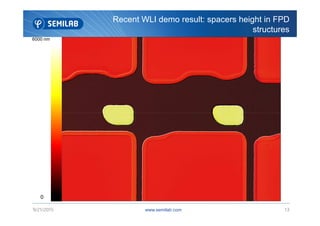

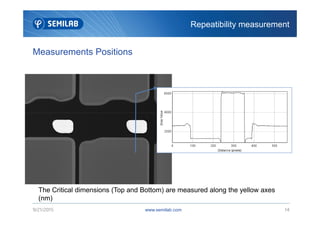

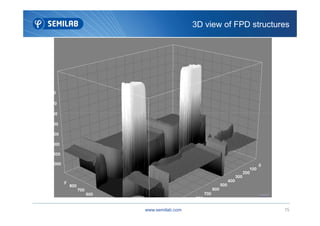

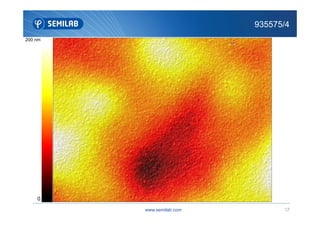

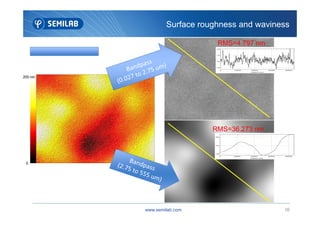

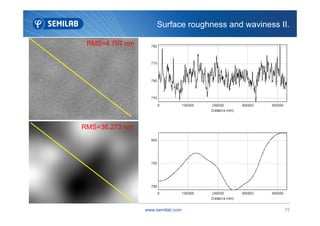

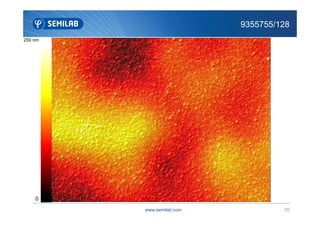

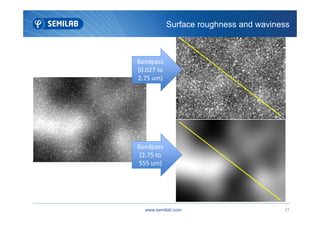

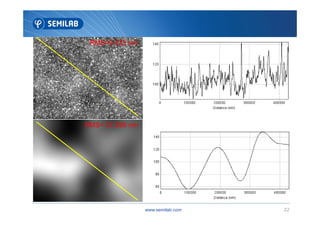

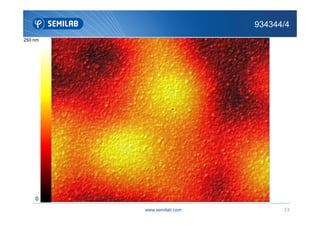

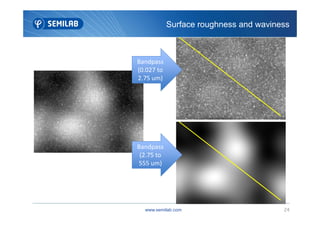

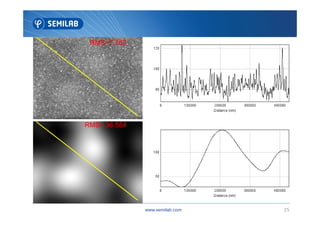

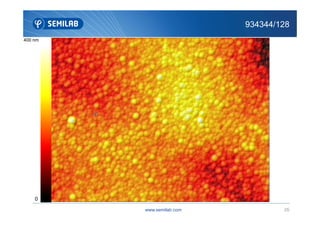

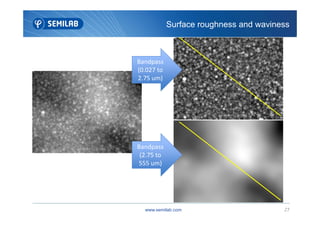

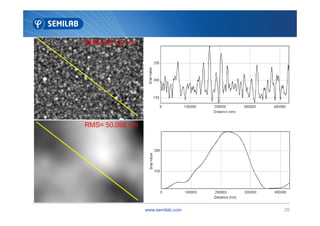

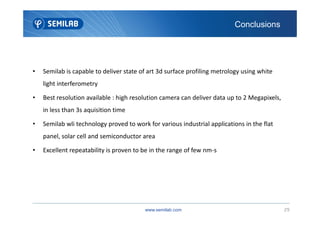

The document discusses the theory and application of white light interferometry for 3D profilometry, emphasizing its capabilities in measuring surface roughness and step heights with high speed and resolution. It highlights the use of a broadband white light source, the non-destructive nature of the technique, and the repeatability of measurements. Semilab, the company referenced, demonstrates successful applications in various industries including flat panels, solar cells, and semiconductors, achieving impressive measurement accuracy and speed.