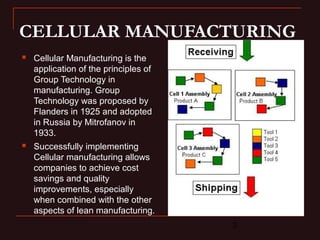

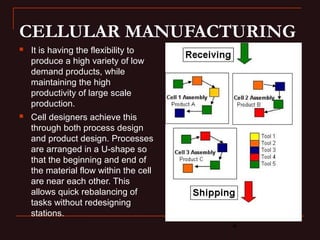

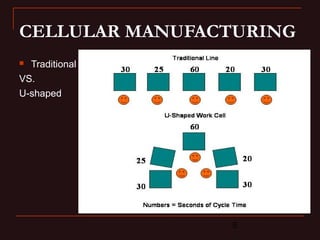

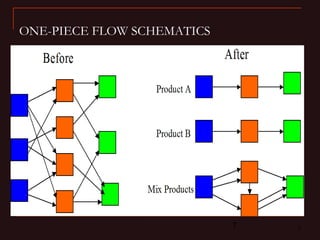

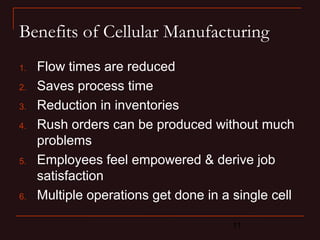

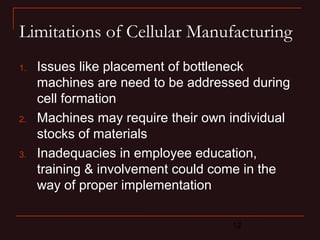

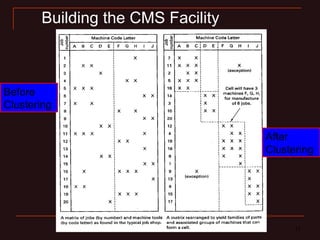

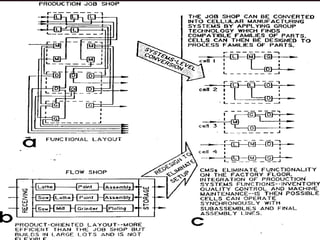

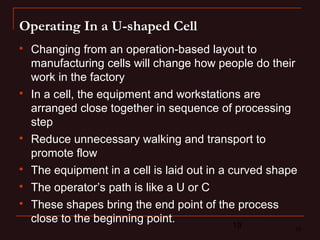

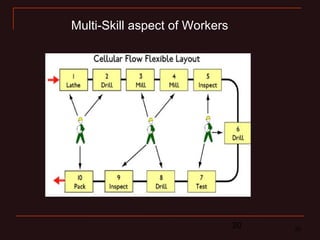

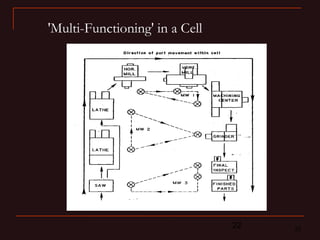

The document discusses cellular manufacturing and its key concepts. Cellular manufacturing involves grouping parts that require similar processing into manufacturing cells. Within each cell, equipment and workstations are arranged closely together in the sequence of processing steps to promote efficient one-piece flow production. It aims to minimize waste by utilizing flexible workers who can operate multiple machines and continuously improve processes.