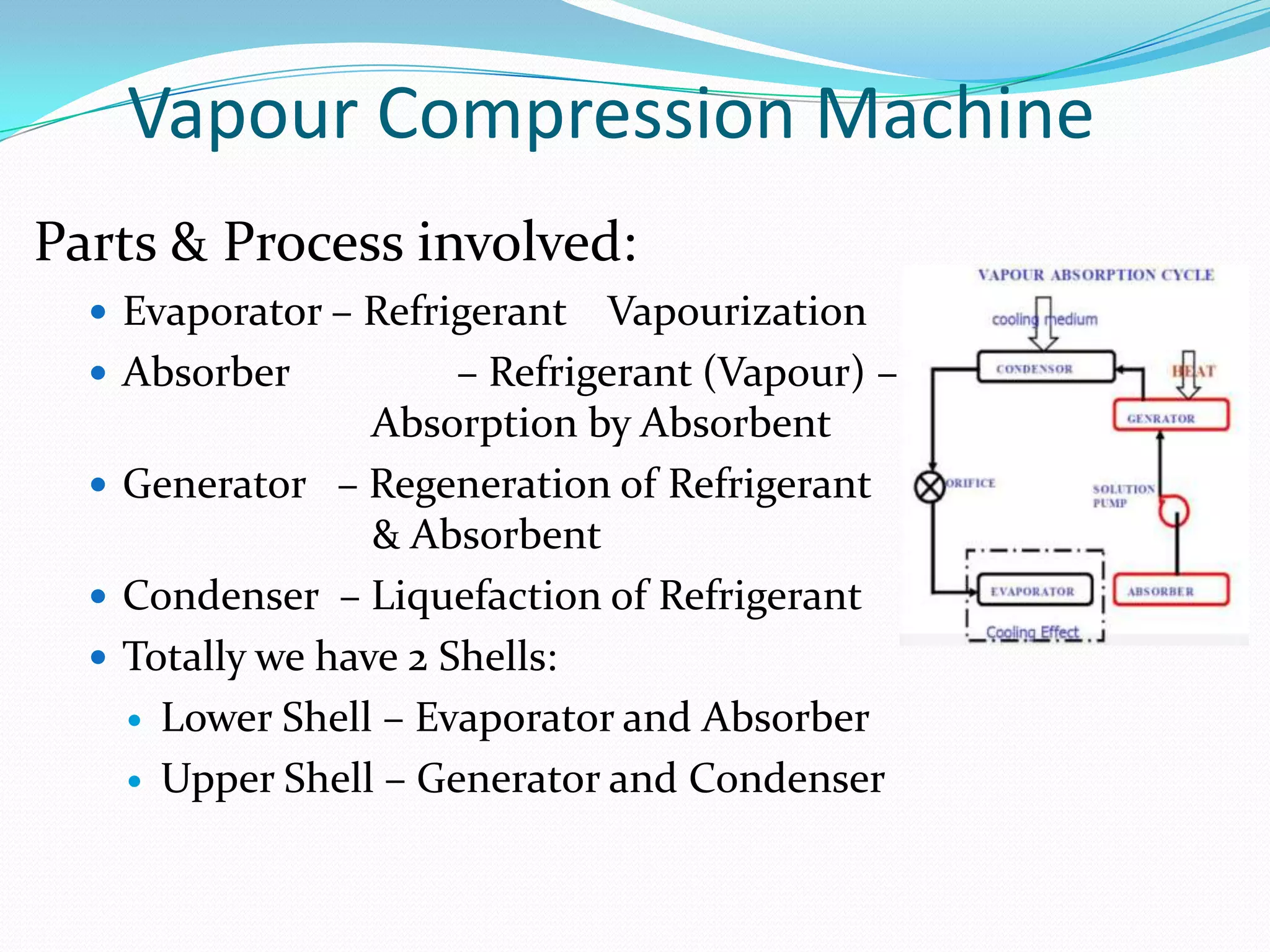

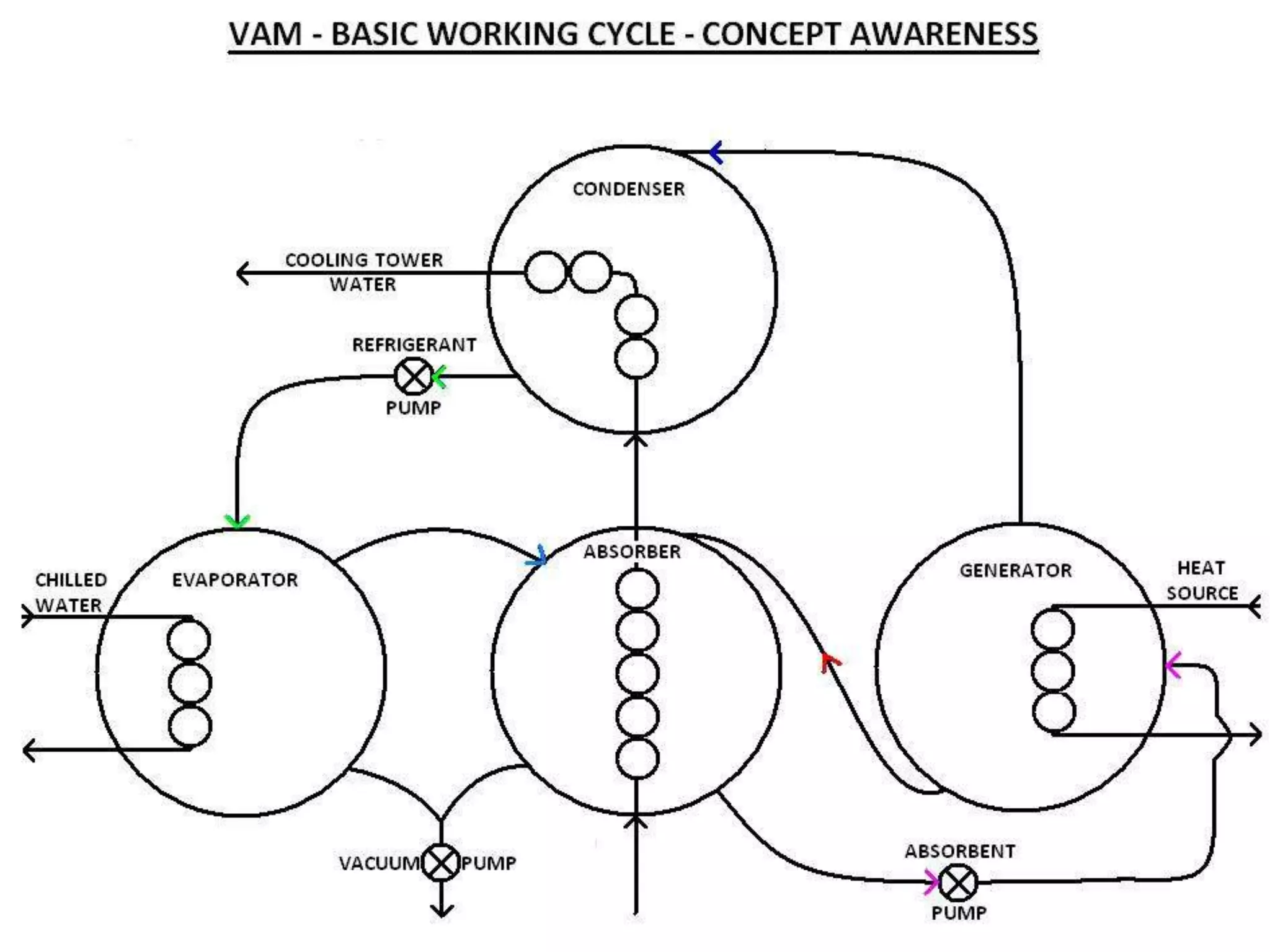

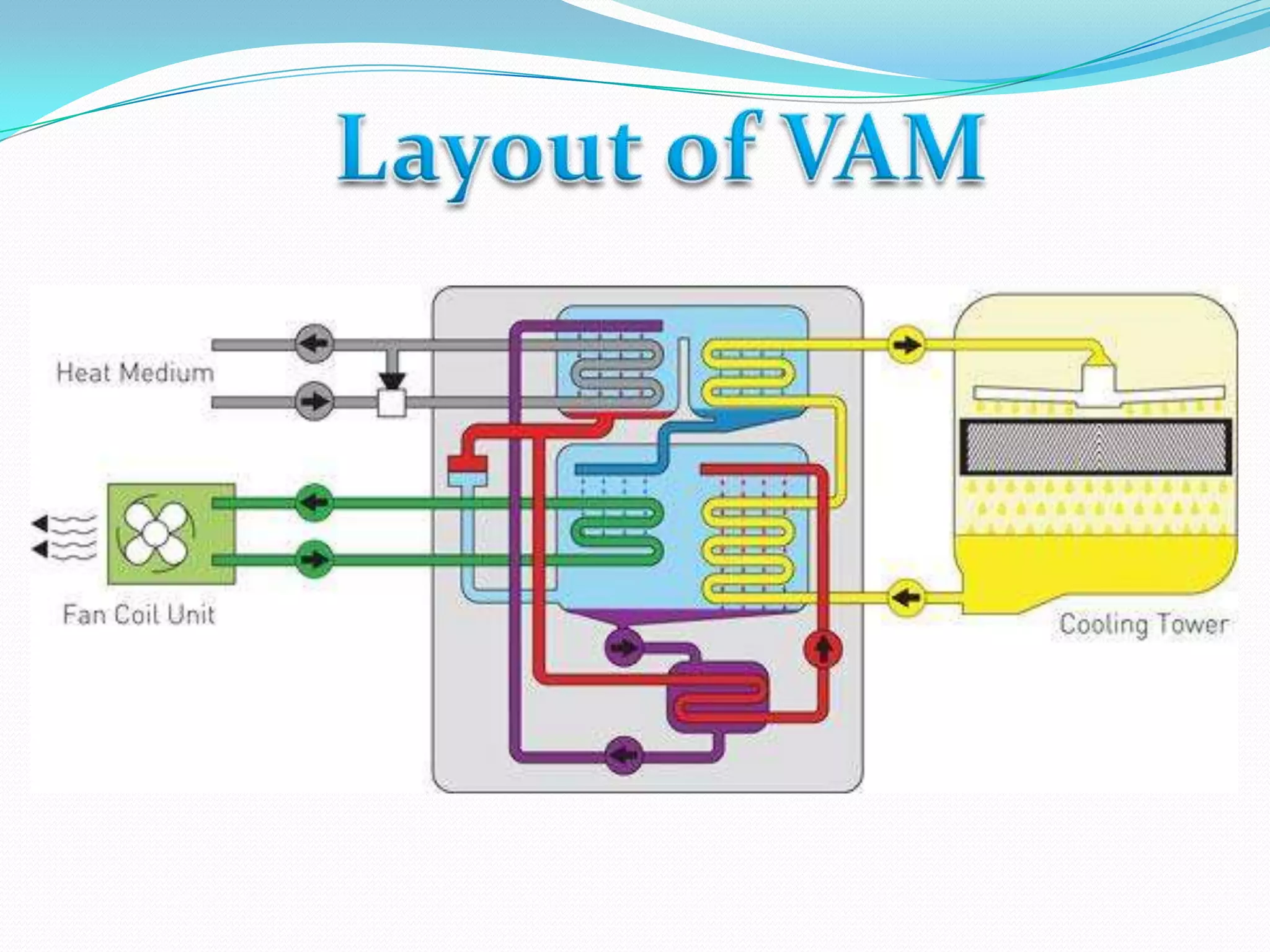

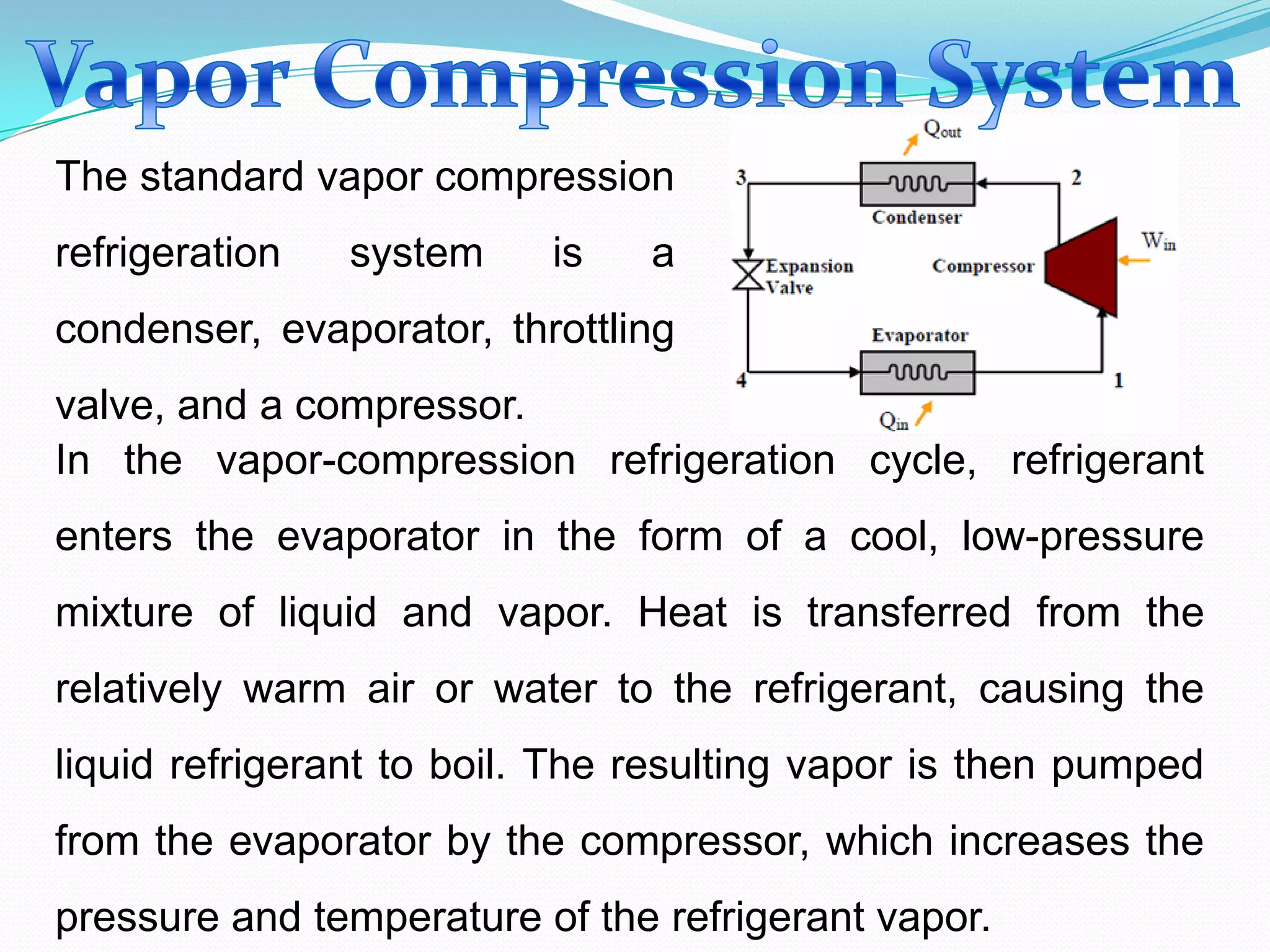

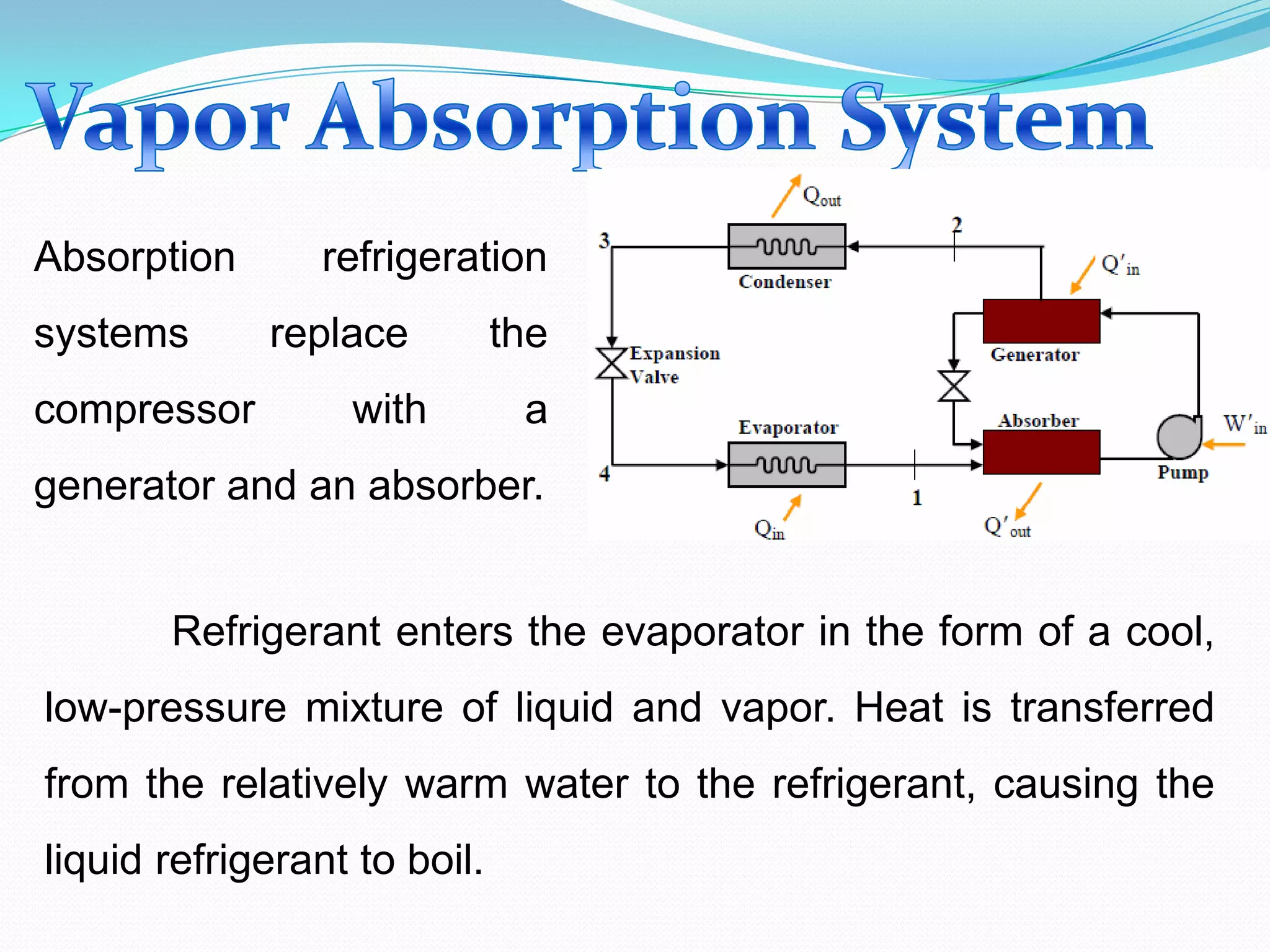

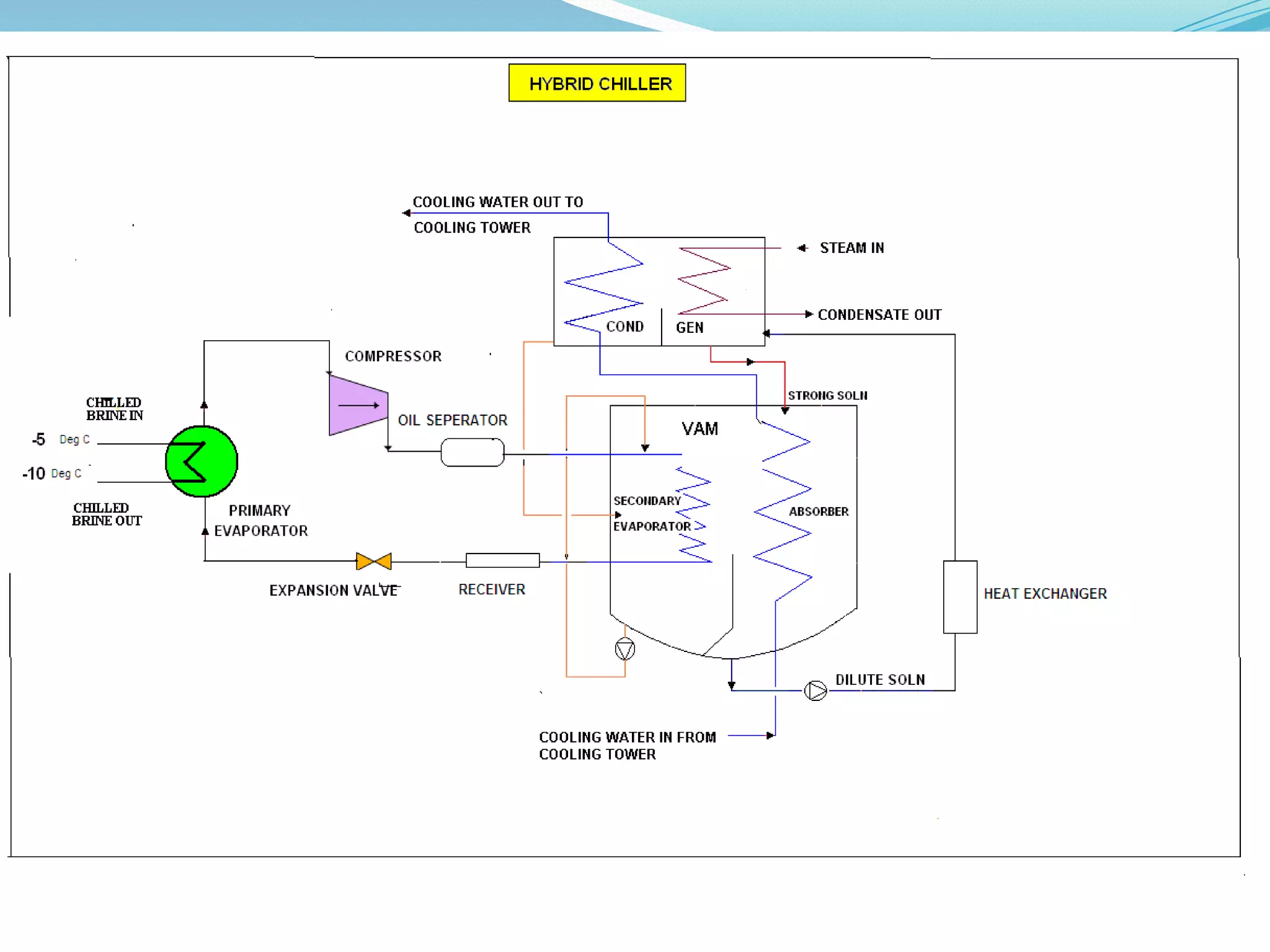

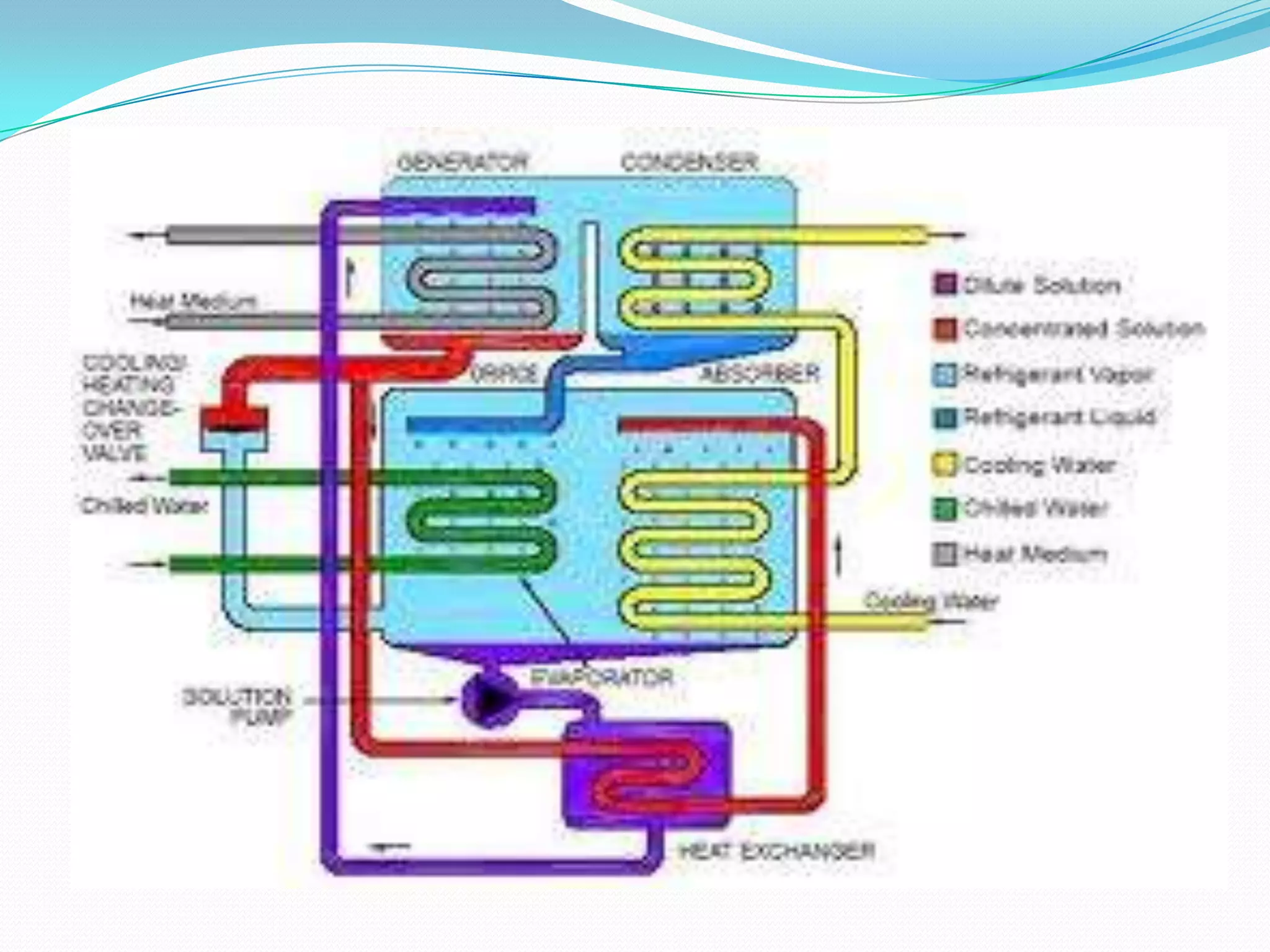

The document describes the key components and processes in a vapor absorption refrigeration system:

1) An evaporator where refrigerant vaporizes and absorbs heat, 2) An absorber where refrigerant vapor is absorbed by an absorbent, releasing heat, 3) A generator where heat regenerates the refrigerant and absorbent, and 4) A condenser where refrigerant condenses and liquefies. Heat from a heat source like steam drives the process without the need for a compressor.